Plasma processing apparatus having flexible dielectric sheet

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problem of difficulty in changing the distance between upper and lower electrodes, and achieve the effects of strong radio frequency current passing ability, long service life, and prevention of metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

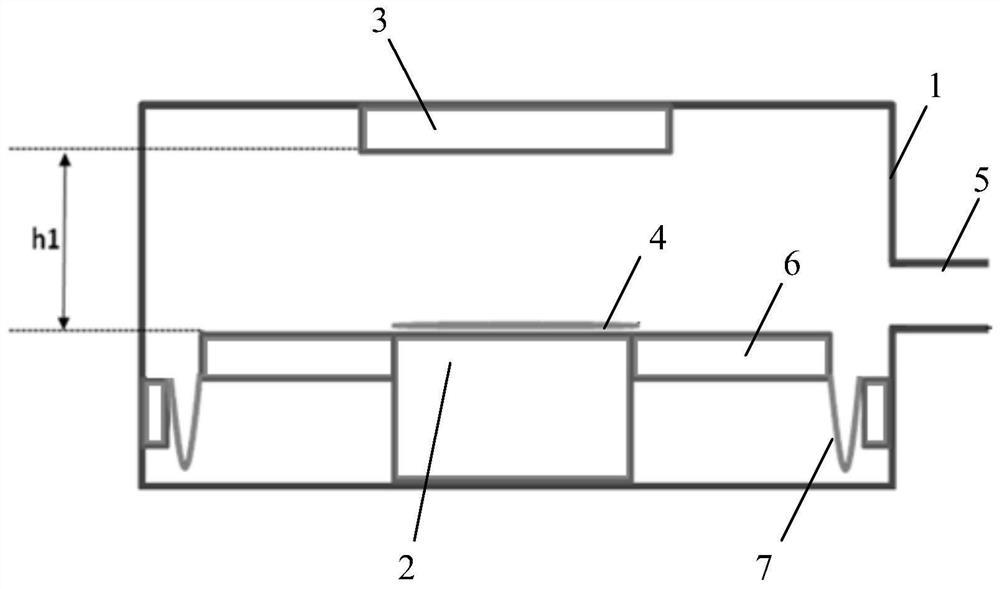

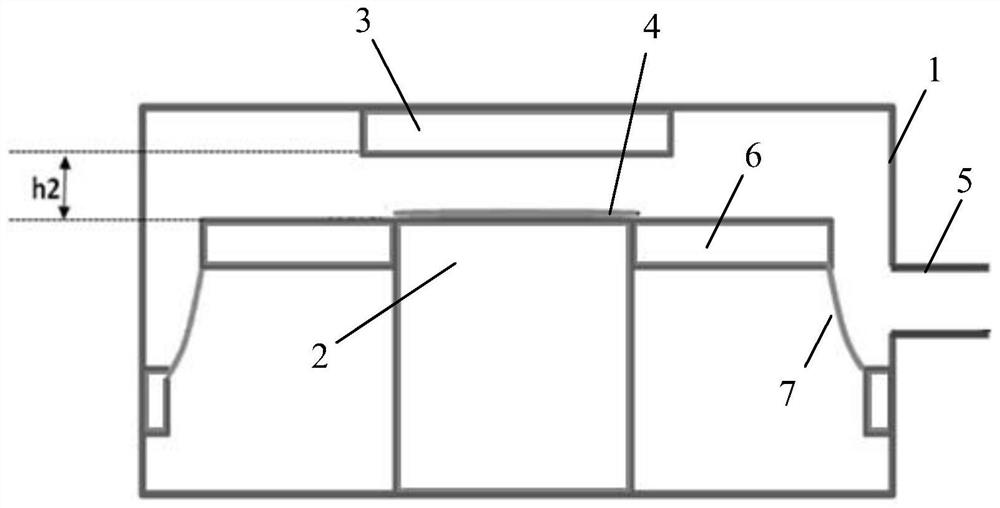

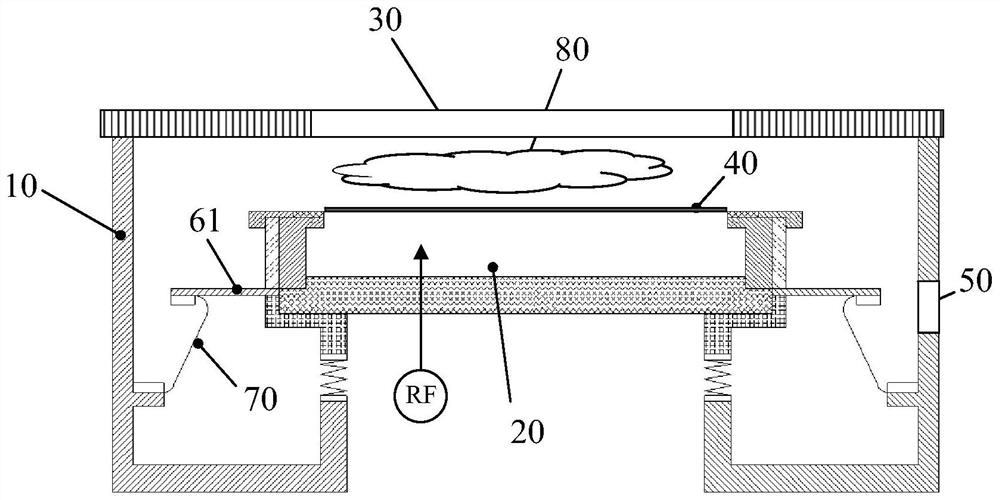

[0040] A plasma processing device provided by the present invention, with image 3 A capacitively coupled plasma processing device is shown as an example, including a vacuum reaction chamber 10 surrounded by the outer wall of the chamber, a base 20 is arranged in the reaction chamber 10, and the top of the base 20 is fixed by an electrostatic chuck Substrate 40; an inlet device for introducing reaction gas into the reaction chamber 10 is provided above the base 20, such as a shower head 30; a processing area is between the shower head 30 and the base 20, and the processing area Surrounded by the cavity of the reaction chamber 10; one side of the cavity is provided with a film transfer port 50, which is convenient for the manipulator to take and place the substrate 40.

[0041] The shower head 30 is used as the upper electrode, and the base 20 is used as the lower electrode. High-frequency radio frequency power can be applied to the upper electrode or the lower electrode to dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com