Spindle structure of drilling and milling center machine tool

A technology of machine tool spindles and drilling and milling centers, applied in the field of machine tools, can solve problems such as weak drilling capabilities and low-precision machining centers, and achieve the effect of solving high-torque cutting problems and increasing radial rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

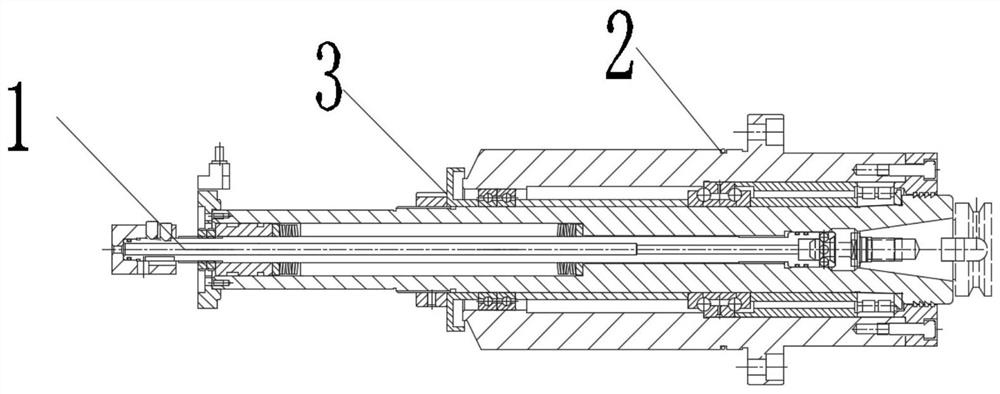

[0028] like figure 1 As shown, a main shaft structure of a drilling and milling center machine tool includes a main shaft 1, a main shaft sleeve 2 and a matching assembly 3, the main shaft 1 is arranged inside the main shaft sleeve 2, and the matching assembly 3 is arranged between the main shaft 1 and the main shaft sleeve 2.

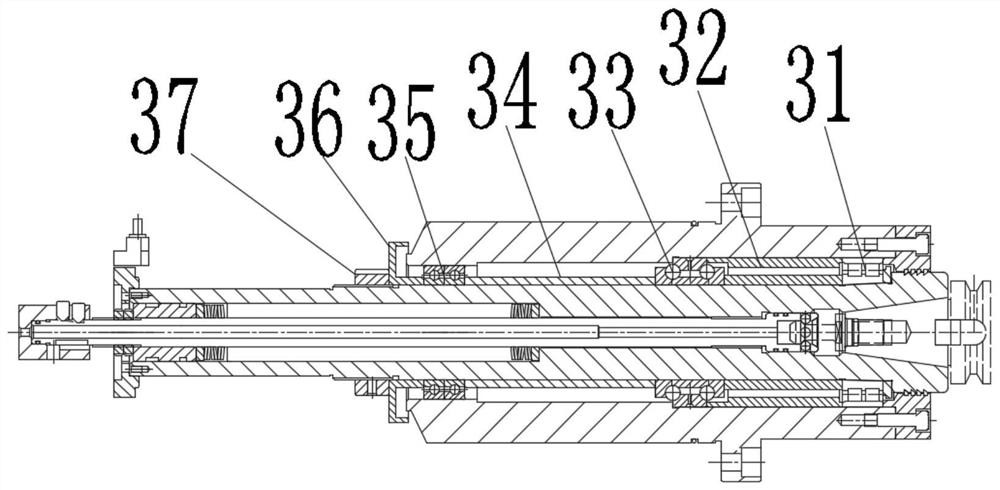

[0029] like figure 2 As shown, the matching assembly 3 includes a double-row radial cylindrical roller bearing 31, a two-way thrust angular contact ball bearing 32, a spacer set 33, a third spacer 34, a deep groove ball bearing 35, an oil deflector ring 36 and a second lock Tight nut 37, double-row radial cylindrical roller bearing 31 is nested in the tail end of main shaft 1, bidirectional thrust angular contact ball bearing 32 is nested in the middle of main shaft 1, spacer set 33 is arranged on the outer periphery of main shaft 1, spacer set 33 two Two-row radial cylindrical roller bearings 31 and two-way thrust angular contact ball bearings 32 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com