Intelligent production line for producing refractory bricks

A production line and refractory brick technology, which is applied in the field of refractory bricks, can solve the problems of refractory brick consumption and large manpower, and achieve the effects of saving time, improving efficiency and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

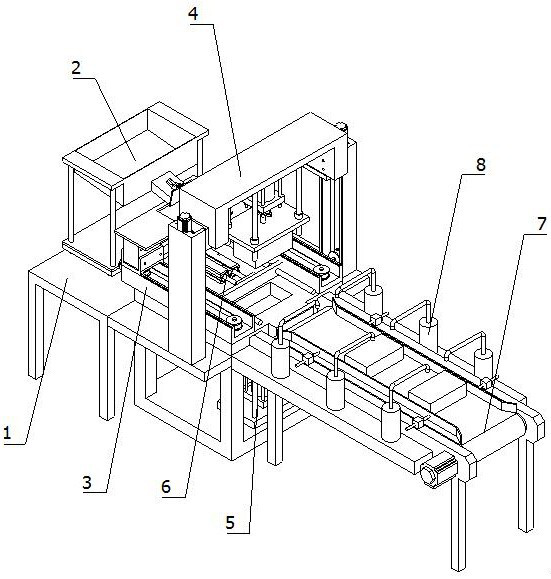

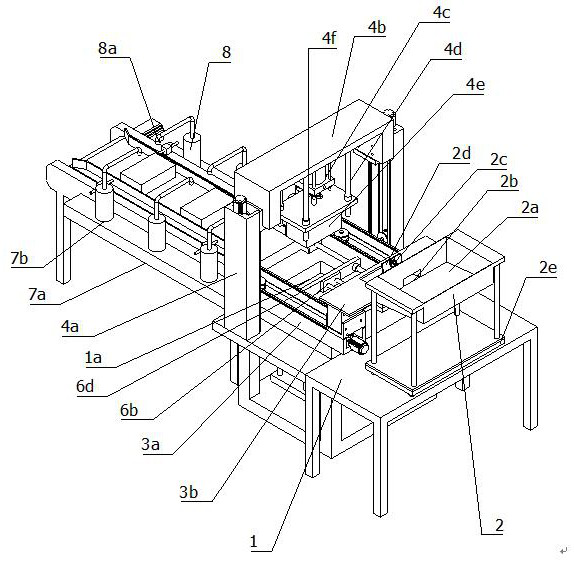

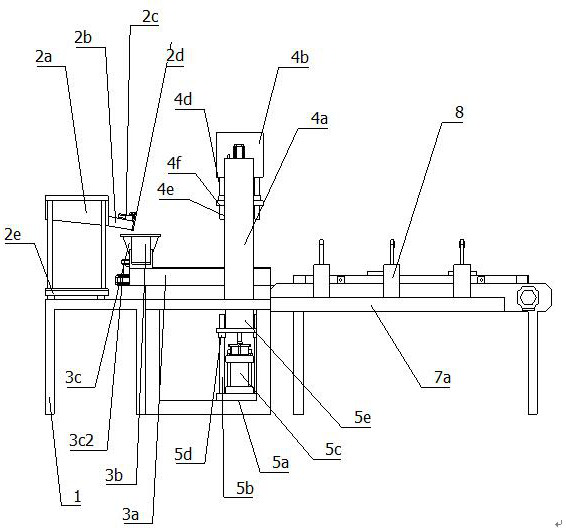

[0053] like figure 1 As shown, in order to achieve the purpose of automatic pressure molding of refractory bricks from raw materials, to solve the technical problem of consuming a lot of manpower in the production of refractory bricks, an intelligent production line for the production of refractory bricks includes,

[0054] Workbench 1;

[0055] The feeding device 2 is installed on the upper side of the workbench 1;

[0056] The feeding device 3 is installed horizontally on the workbench 1, the feeding device 3 is located on the side of the working end of the feeding device 2, and the working direction of the feeding device 3 is set to the horizontal direction;

[0057] The pressurizing device 4, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com