Tempered glass controllable steady-flow heating method based on heating furnace

A technology of tempered glass and heating method, applied in the field of machinery, can solve the problems of uneven heating, easy to cause harmonics, current fluctuations, etc., and achieve the effects of uniform control, stable current and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

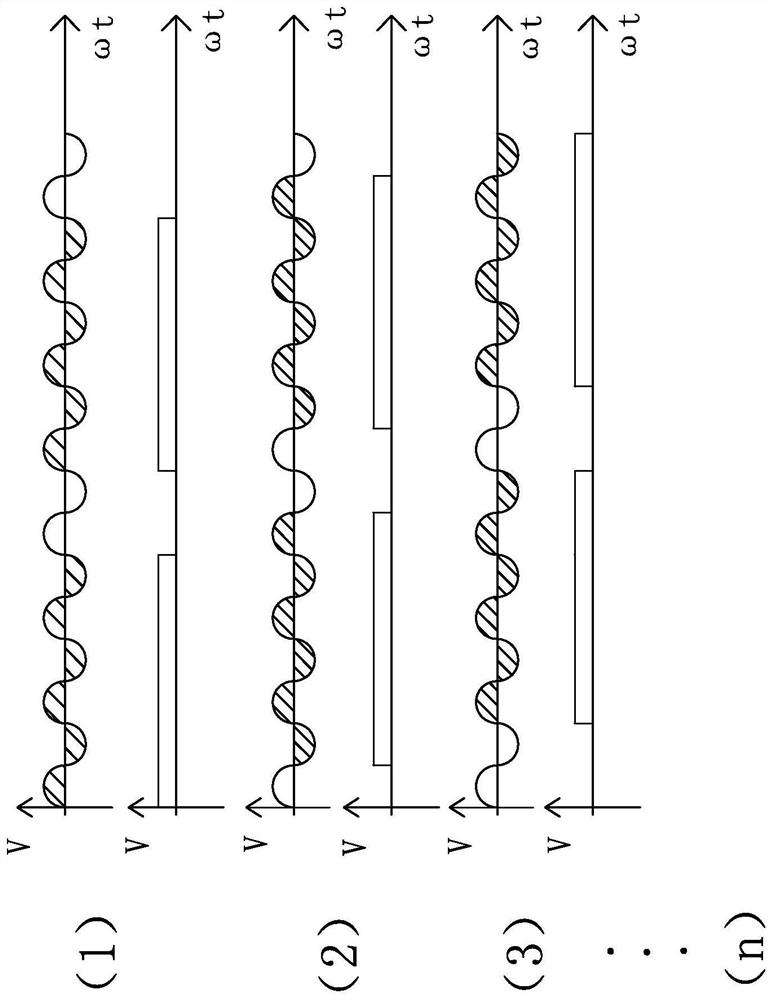

[0030] figure 1 In the two figures in group (1), the upper figure is a schematic diagram of the output voltage of the solid state relay, and the lower figure is a schematic diagram of the pulse signal. Group (2) and group (3) refer to group (1), and follow the rules until group (n). The example state in this figure is the initial stage of heating, and the mains power is 50Hz. figure 1 The middle is sequentially delayed by 0.5Hz, that is, 0.01s; the pulse period is 4Hz, that is, 0.08s, and the duty cycle is 75%. This situation is one of them and can be adjusted according to the actual situation.

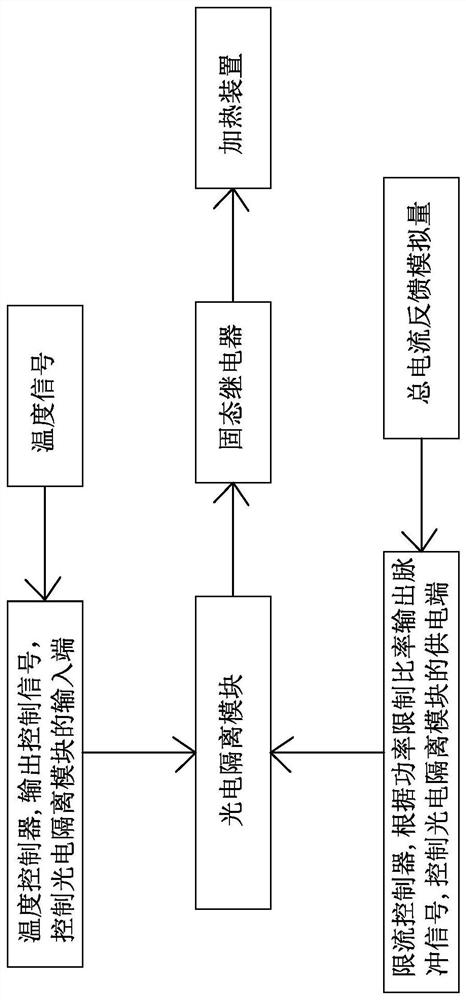

[0031] Such as Figure 1-2 As shown, a controllable and steady flow heating method for tempered glass based on a heating fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com