Reinforced glass fiber impregnating compound as well as preparation method and application thereof

A technology of glass fiber and sizing agent, applied in the field of glass fiber sizing agent, can solve the problems of affecting the impregnating mechanical properties of products, poor similar compatibility, and unfavorable comprehensive performance of SMC products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

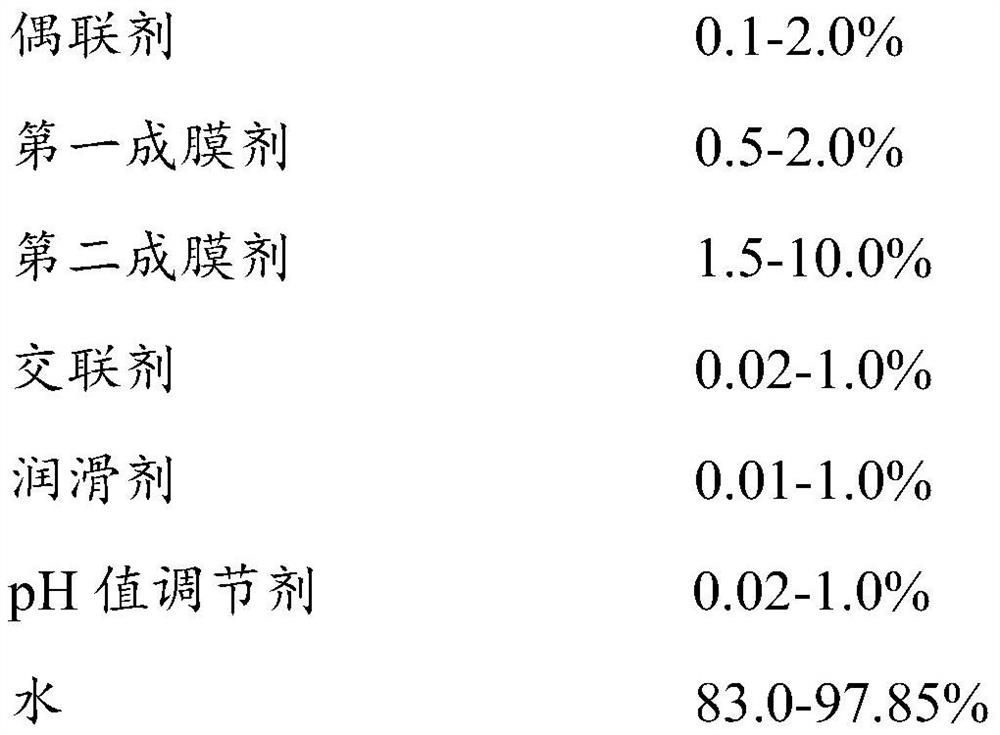

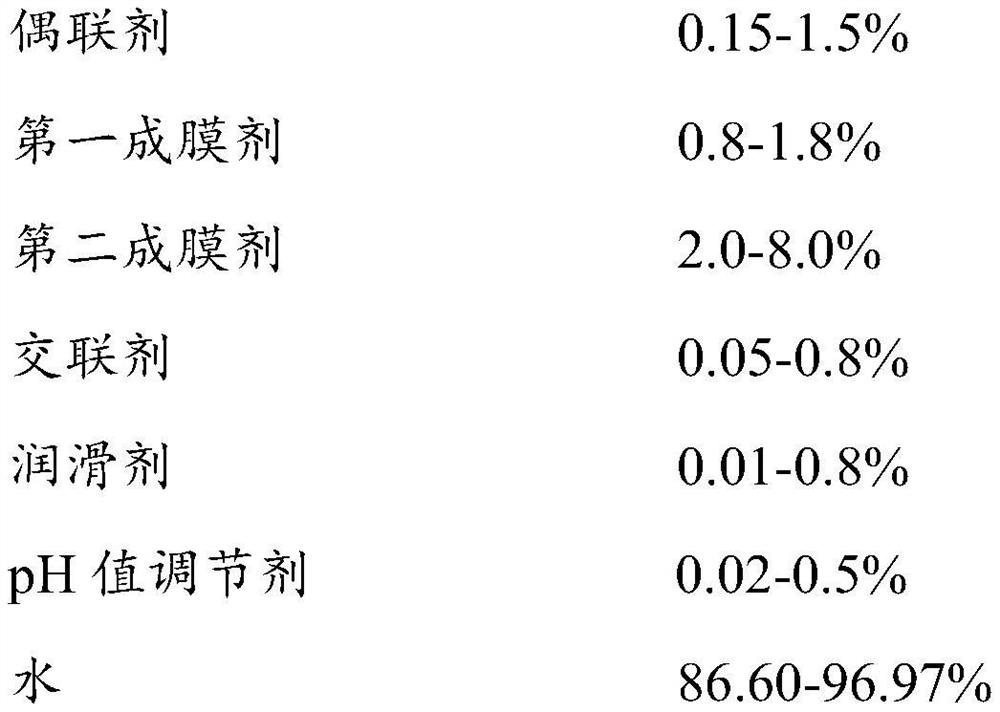

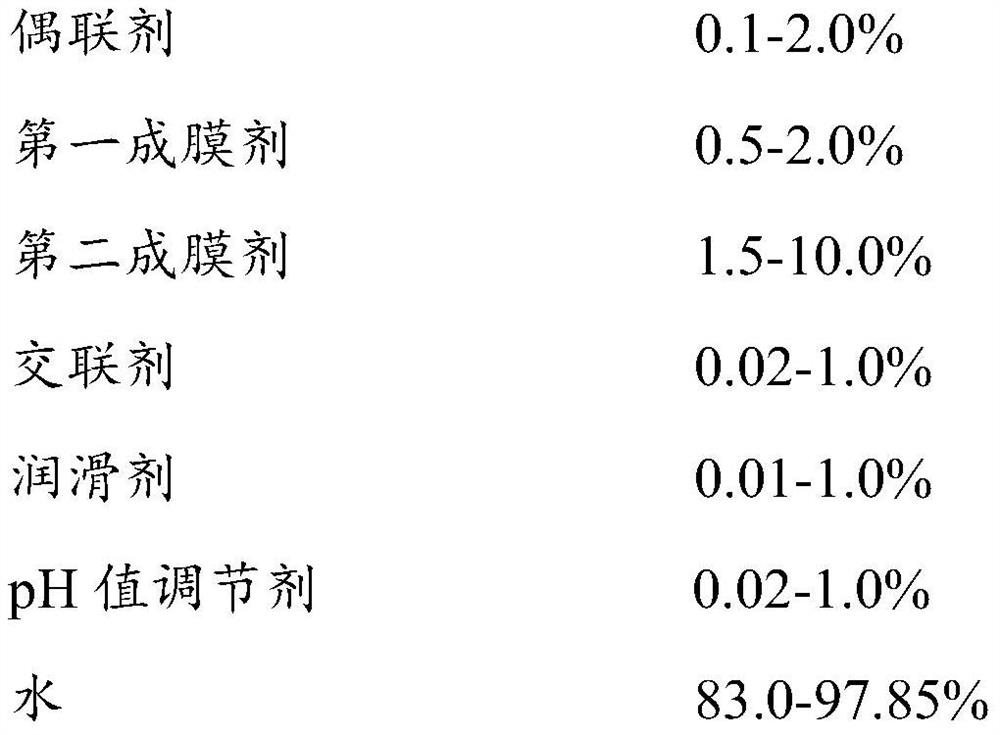

Method used

Image

Examples

preparation example Construction

[0060] According to the prescription of embodiment 1-10 in table 1, strengthened glass fiber sizing is prepared, and its preparation method comprises the steps::

[0061] 1) Add water 30 to 50 times the mass of the first coupling agent in the first container, adjust it to acidity with a pH adjuster, stir and add the first coupling agent until the mixture is uniform, and disperse until clarification;

[0062] 2) Add water equivalent to the mass of the second coupling agent of 30 to 50 in the second container, adjust it to acidity with a pH regulator, add the second coupling agent with stirring, and disperse evenly until clarification;

[0063] 3) Add 2 to 4 times the normal temperature water of the epoxy emulsion into the third container, then add the epoxy emulsion, and stir until evenly dispersed;

[0064] 4) Add 2 to 4 times the normal temperature water of the polyurethane emulsion into the fourth container, then add the polyurethane emulsion, and stir until evenly dispersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com