Yellow rice wine brewing fermentation barrel with cold air stirring and rapid cooling functions and brewing process

A technology of rice wine brewing and fermenting barrels, which is applied in the field of wine making, can solve the problems of slow cooling speed, uneven cooling, residue, etc., and achieve the effects of uniform cooling, accelerated cooling, and eliminating the need for stirring equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

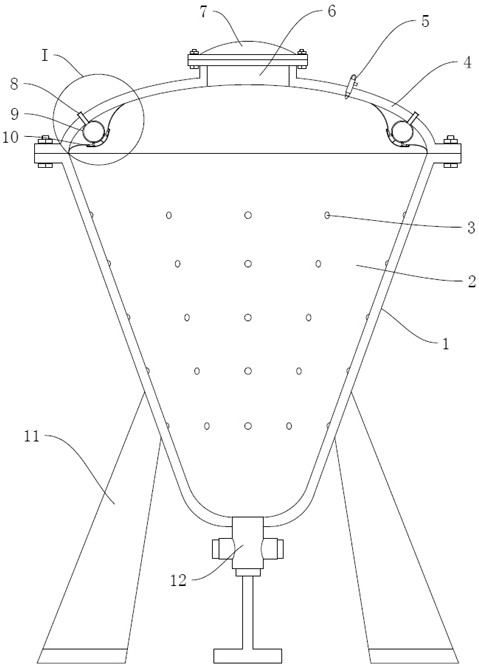

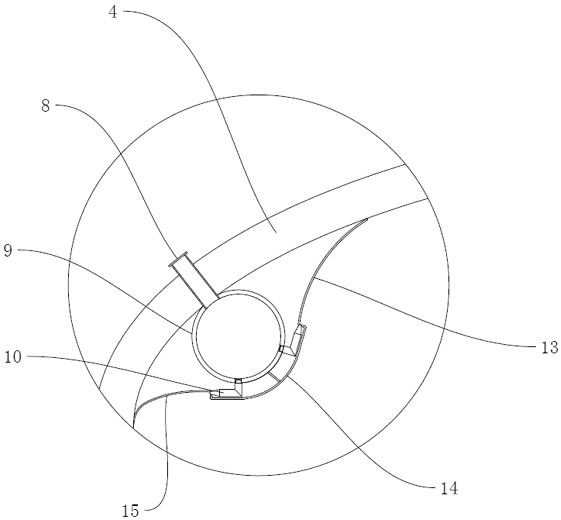

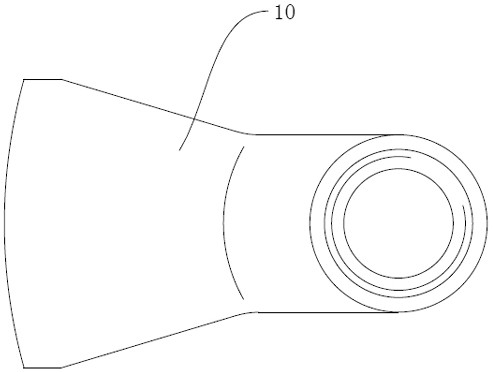

[0031] Such as figure 1 figure 2 image 3 Figure 4 Shown, a kind of rice wine brewing fermenter, comprises barrel body 1 and barrel cover 4.

[0032] The barrel body is in an inverted cone shape, with the large diameter end facing upwards and an opening is set, the barrel cover covers the opening, the small diameter end faces downward, the small diameter end is an arc-shaped bottom, and the middle of the small diameter end is the lowest position, and the outside of the barrel body is connected with supporting feet 11 , there are four supporting legs, and the four supporting legs are arranged symmetrically, and the supporting legs prop up the barrel and keep the axis of the barrel in the vertical direction. A discharge pipe 12 is arranged at the bottom of the staving, and the discharge pipe communicates with the middle of the small diameter end. There is a safety valve inside the discharge pipe, and the safety pressure of the safety valve is set according to the weight of...

Embodiment 2

[0038] Such as Figure 5 Shown, a kind of rice wine brewing fermenter, differs from embodiment 1 in that: barrel body interior is provided with cross bar 19, and cross bar passes through the axis of barrel body and perpendicular to the axis line of barrel body, and cross bar is in 1 / 2 of the barrel body. 2 heights, the crossbar is a hollow structure, and the crossbar is provided with a temperature sensor 3, one of the temperature sensors corresponds to the central position of the barrel body, and the sensing line of the temperature sensor is drawn out of the barrel through the inside of the crossbar. Refer to Example 1 for all the other structures.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap