Scroll compressor

A scroll compressor and moving scroll technology, applied in the field of compressors, can solve problems such as over-compression and increased compression power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

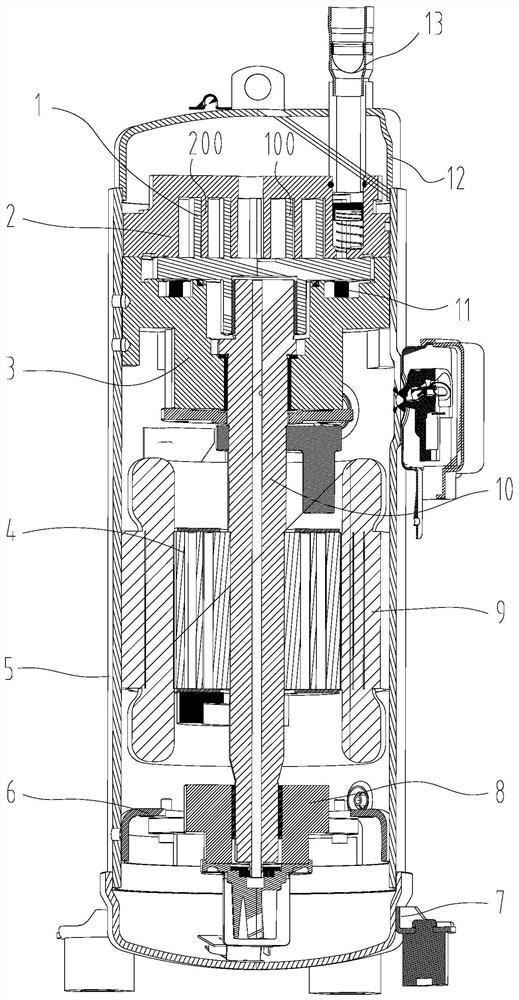

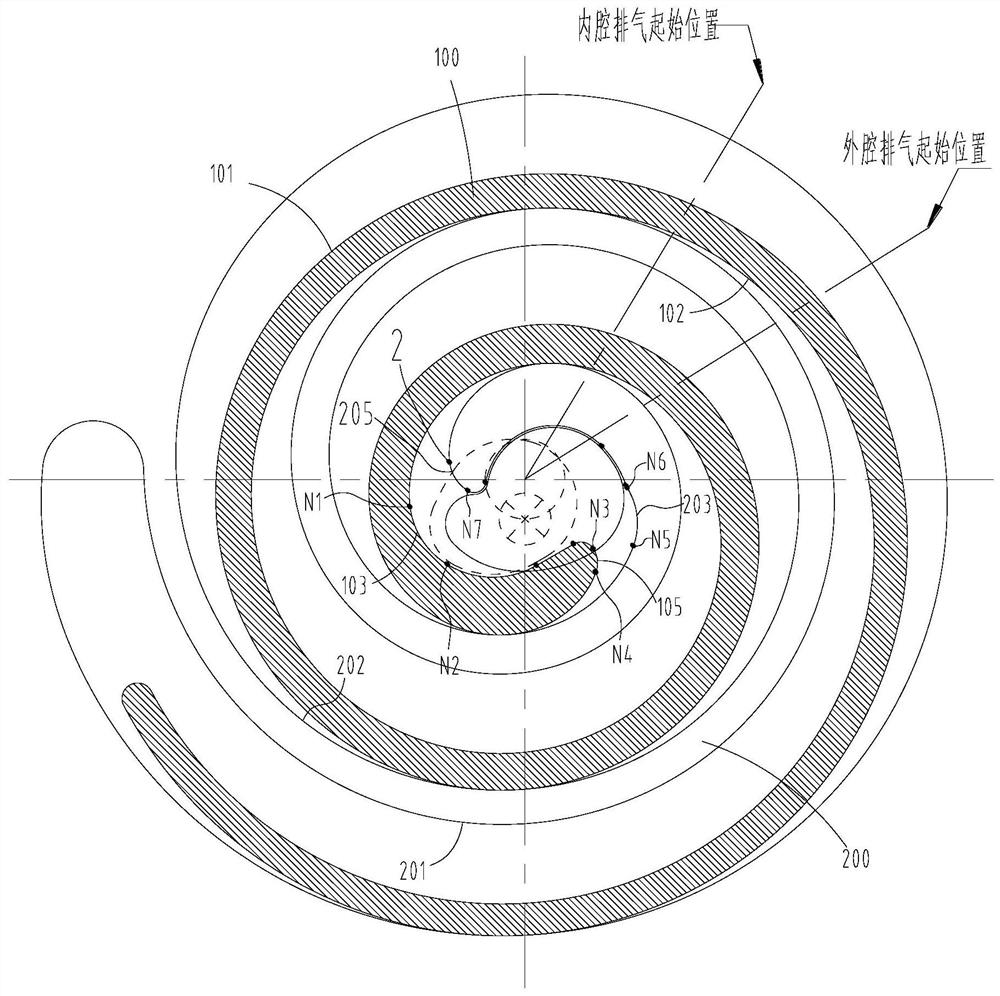

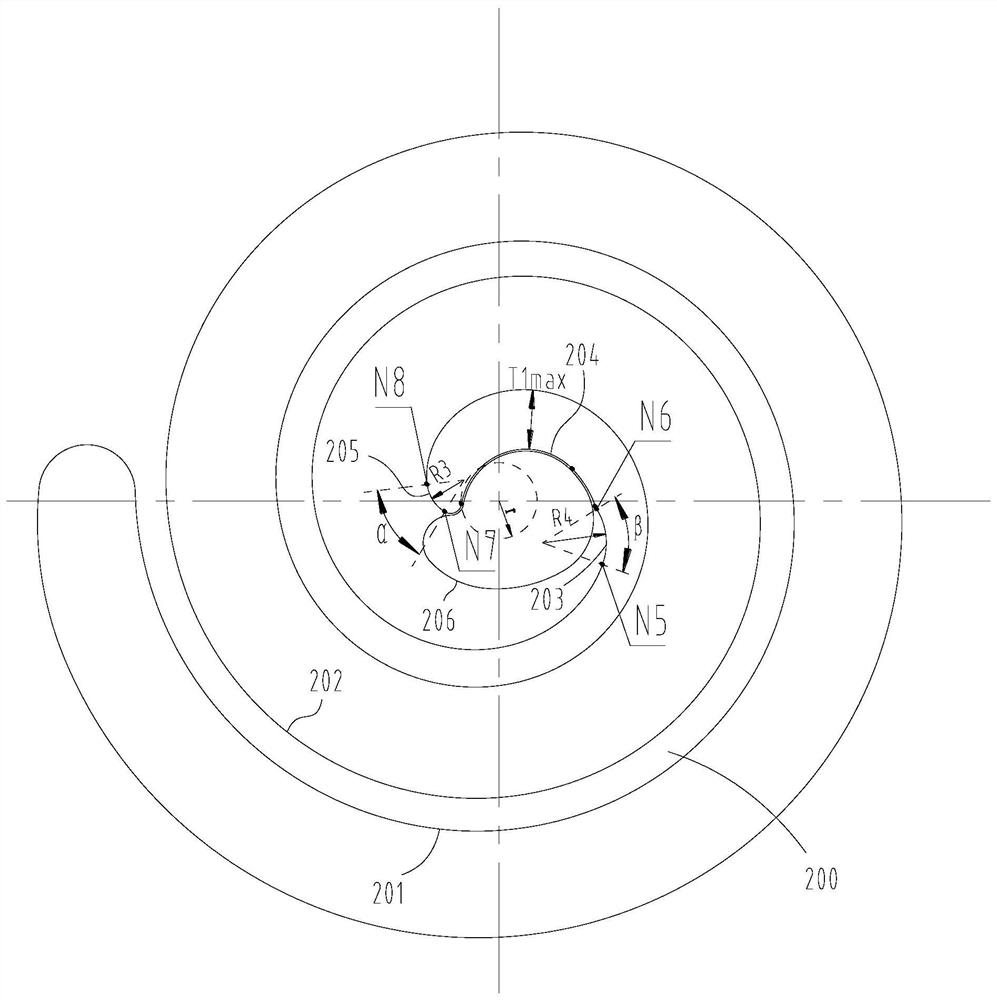

[0028] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present application, the scroll compressor includes a movable scroll 1, a fixed scroll 2, an upper bracket 3, a rotor 4, a casing 5, a lower support ring 6, a lower cover 7, a lower bracket 8, a motor 9. Crankshaft 10, Oldham slip ring 11, upper cover 12, etc. The motor 9 is fixed on the housing 5 through a shrink fit, and the upper bracket 3 is fixed on the housing 5 through eight-point welding. The phase angle difference between the movable scroll 1 and the fixed scroll 2 is 180 degrees, and it is installed on the upper bracket 3. The movable scroll 1 moves under the drive of the crankshaft 10, and meshes with the fixed scroll 2 to form a series of mutually isolated and continuously changing volumes. The crescent-shaped airtight cavity, the fixed scroll 2 is fixed on the upper bracket 3 by screw fasteners. The crankshaft assembly is supported by a lower bracket 8, and the lower bra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap