Quantitative limiting valve for crude oil conveying pipeline

A technology for conveying pipelines and restricting valves, which is applied in the direction of lifting valves, valve details, and valve devices. Effect of service life and damage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

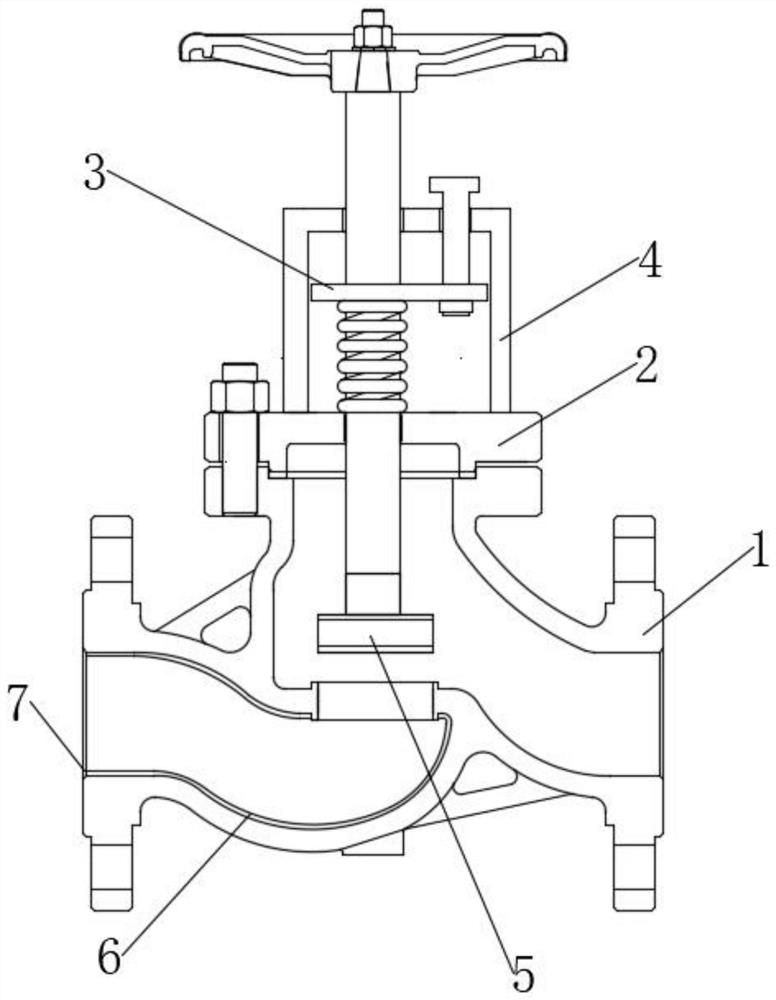

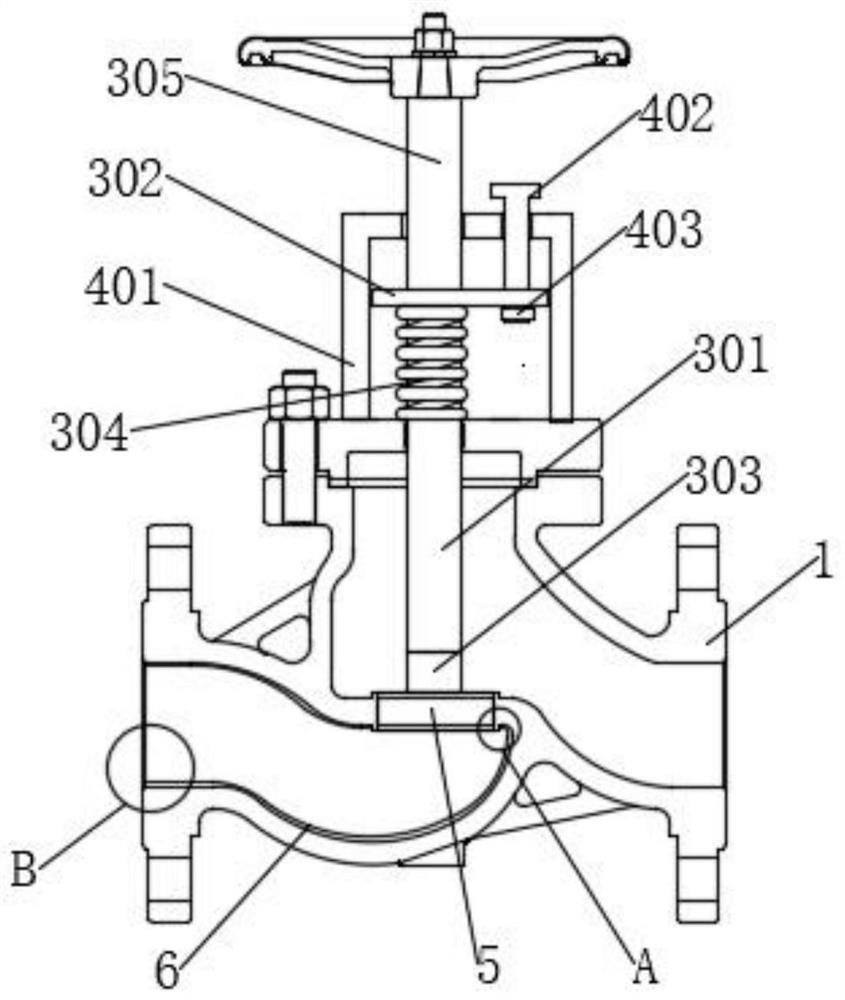

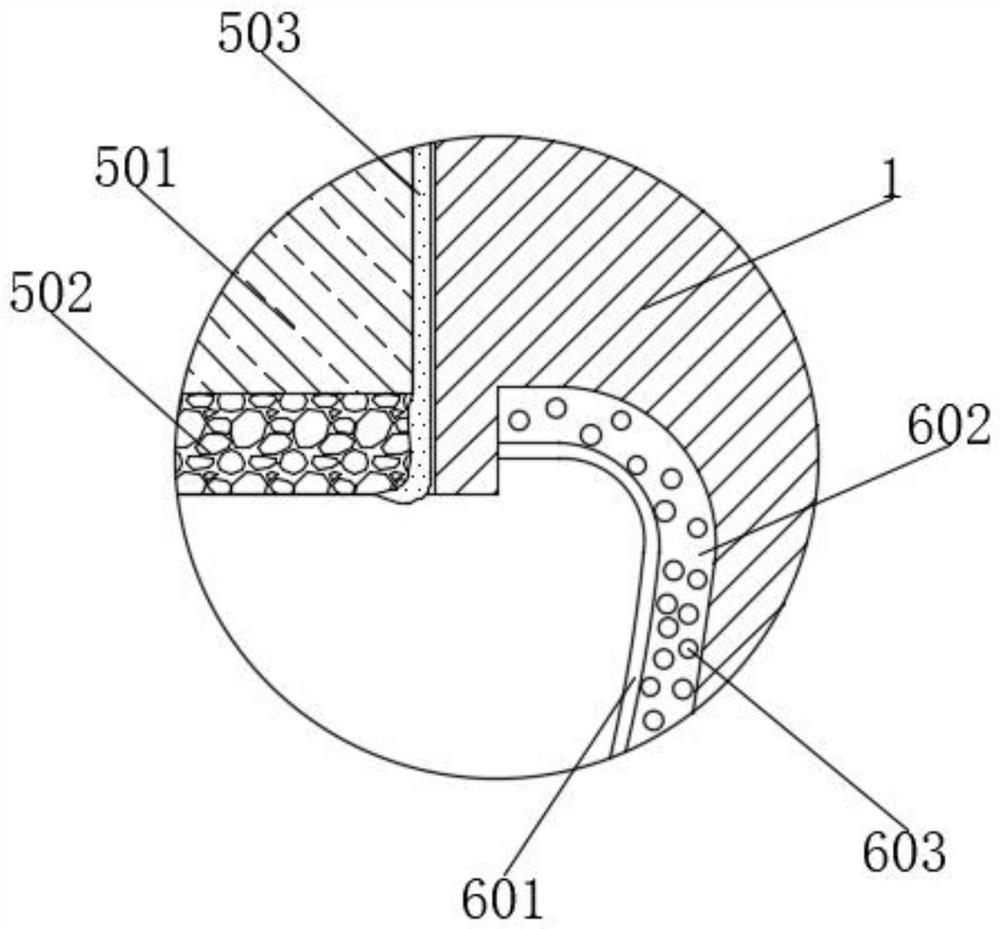

[0034] see Figure 1-2 , a quantitative limiting valve for crude oil transportation pipelines, comprising a valve casing 1, a bonnet 2 is clamped on the upper end of the valve casing 1, an adjusting rod 3 is inserted on the bonnet 2, and an adjusting rod 3 is fixedly connected to the bottom end of the bonnet 2. Rod 3 matching sealing ring, both ends of the valve housing 1 are fixedly connected with flange end caps, the flange end caps are fixedly connected with a fixed ring matching the protective film 6, and the valve body and the valve body are connected through the flange end caps. The pipes are connected, and the flange end cover seals the boundary of the protective film 6 .

[0035] see Figure 1-3 The valve cover 2 is fixedly connected with a pressure regulating mechanism 4, the pressure regulating mechanism 4 includes a housing 401, the housing 401 is screwed with an adjusting bolt 402, and one end of the adjusting bolt 402 located in the housing 401 is rotatably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com