Device and method for measuring tundish liquid level height through robot

A technology of liquid level and tundish, applied in the field of continuous casting and steel casting in iron and steel plants, can solve the problems of time-consuming replacement of parts, cumbersome fixed connection and disassembly, low flexibility of measuring devices, etc., so as to facilitate the guidance of normal production operations, The effect of maintaining high liquid level operation and improving the quality of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

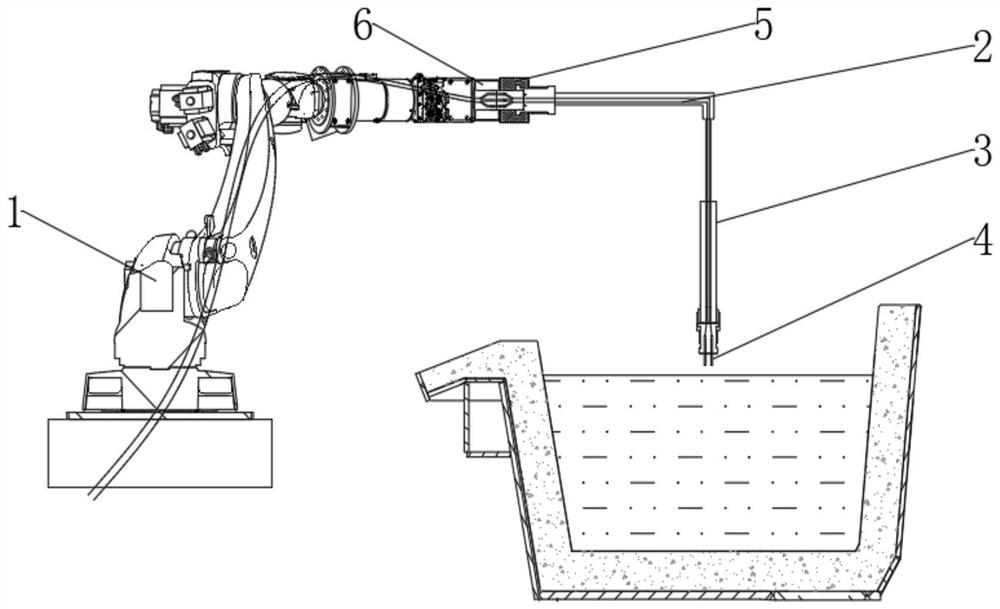

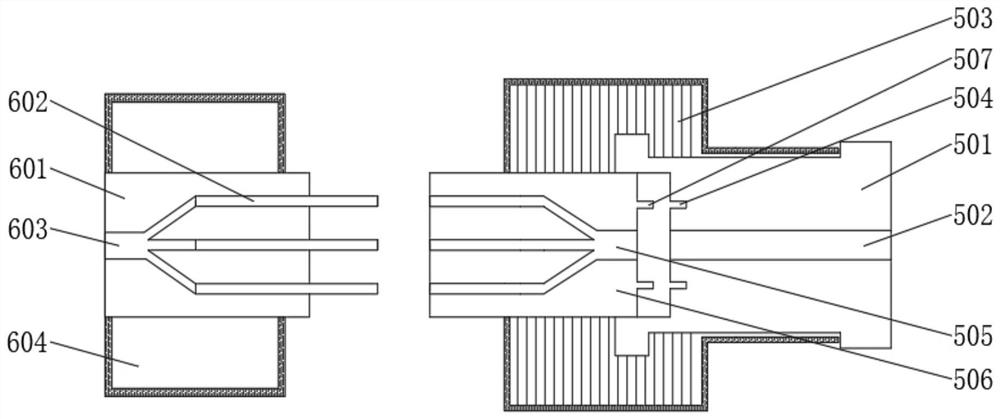

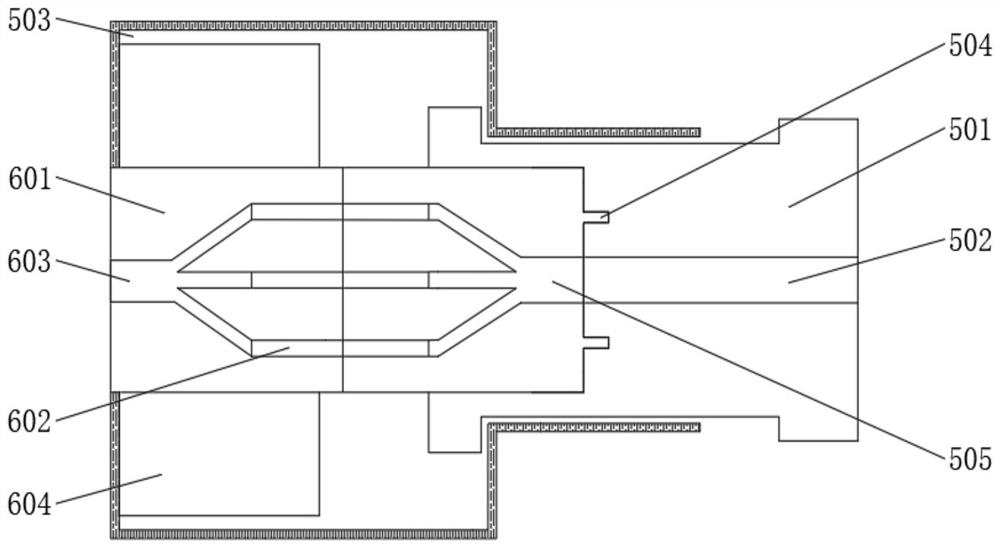

[0043] see Figure 1-4A device for measuring the liquid level of a tundish, comprising a robot 1, the right side of the robot 1 is fixedly connected with a socket 6, the left end of the socket 6 is threadedly connected with an interface 5, and the right end of the interface 5 is fixedly connected with a connector 2, the connector 2 The outer lower right side of the socket is nested with a paper sleeve 3, the end of the connector 2 away from the interface 5 is fixedly connected with a metal sheet 4, the socket 6 includes a socket base 601, and the left end of the socket base 601 is provided with a socket wire groove 603, and the socket base One end of 601 away from the socket wire groove 603 is fixedly connected with a conductive rod 602 inside, a plurality of conductive rods 602 are evenly fixed inside the socket base 601 and extend out of the right end of the socket base 601, and the outside of the socket base 601 is nested and connected with a fixed block 604, The interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com