Accurate modeling method for metal material welding spots

A technology of metal materials and modeling methods, applied in the field of vehicle simulation analysis, which can solve the problems of difficult simulation accuracy of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

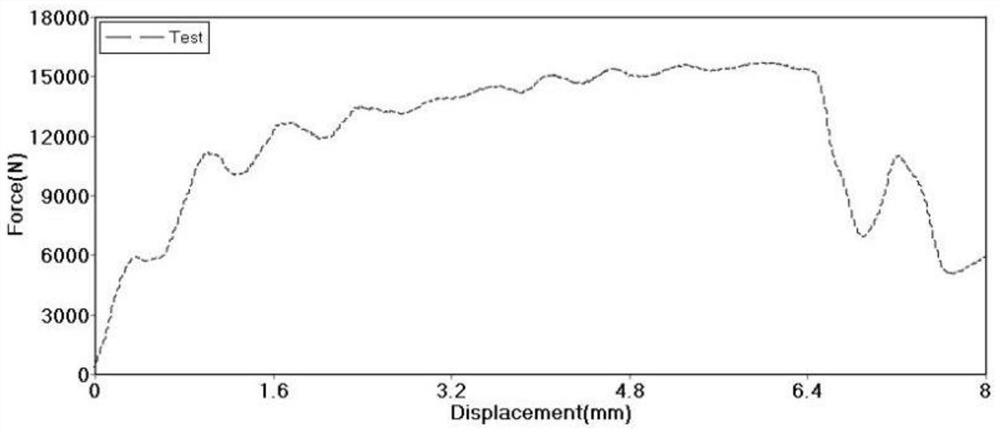

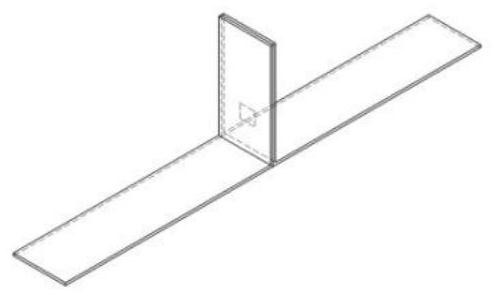

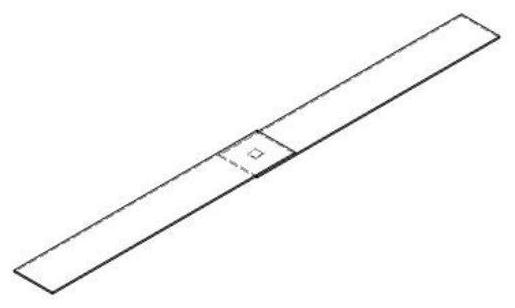

[0025] The specific embodiment of the present invention is to provide an accurate modeling method of metal material solder joints. Since the solder joints are an important component of connecting sheet metal parts, with the deformation of the sheet metal parts during the collision, the solder joints are not subjected to a single load, but a compound load. The force-based solder joint failure judgment needs to decompose the composite stress mode of a single solder joint into tensile force, shear force, peeling bending moment, and plane torque, and conduct simulation analysis and benchmarking respectively. Such as Figure 6 As shown, the precise modeling method of metal material solder joint of the present invention comprises the following steps:

[0026] Step 1: Make lap tensile test, butt joint tensile test and cross tensile test samples with metal materials, measure the thickness of the base metal, the size and position of the solder joints, and obtain different working cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com