Machining performance evaluation of transmission shaft and control method based on key process

A processing performance and control method technology, applied in the direction of comprehensive factory control, genetic rules, gene models, etc., can solve problems such as inaccuracy, limited evaluation indicators, and inability to guarantee working life, and achieve the effect of expanding the optimization range and accurate service life

Active Publication Date: 2022-05-31

BEIHANG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the evaluation of processing performance is based on individual typical processes, and the evaluation indicators are limited, which cannot meet the life evaluation requirements of the transmission shaft.

In addition, process optimization is carried out for a single process, ignoring the influence of other process parameters. Such an evaluation is one-sided and inaccurate. It is difficult to accurately optimize process parameters and cannot guarantee the overall working life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The present invention is further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] Step S5: based on the genetic algorithm, the key process parameters of the transmission shaft are optimized.

[0040] N=N

[0041] In the formula: N is the total life. N

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

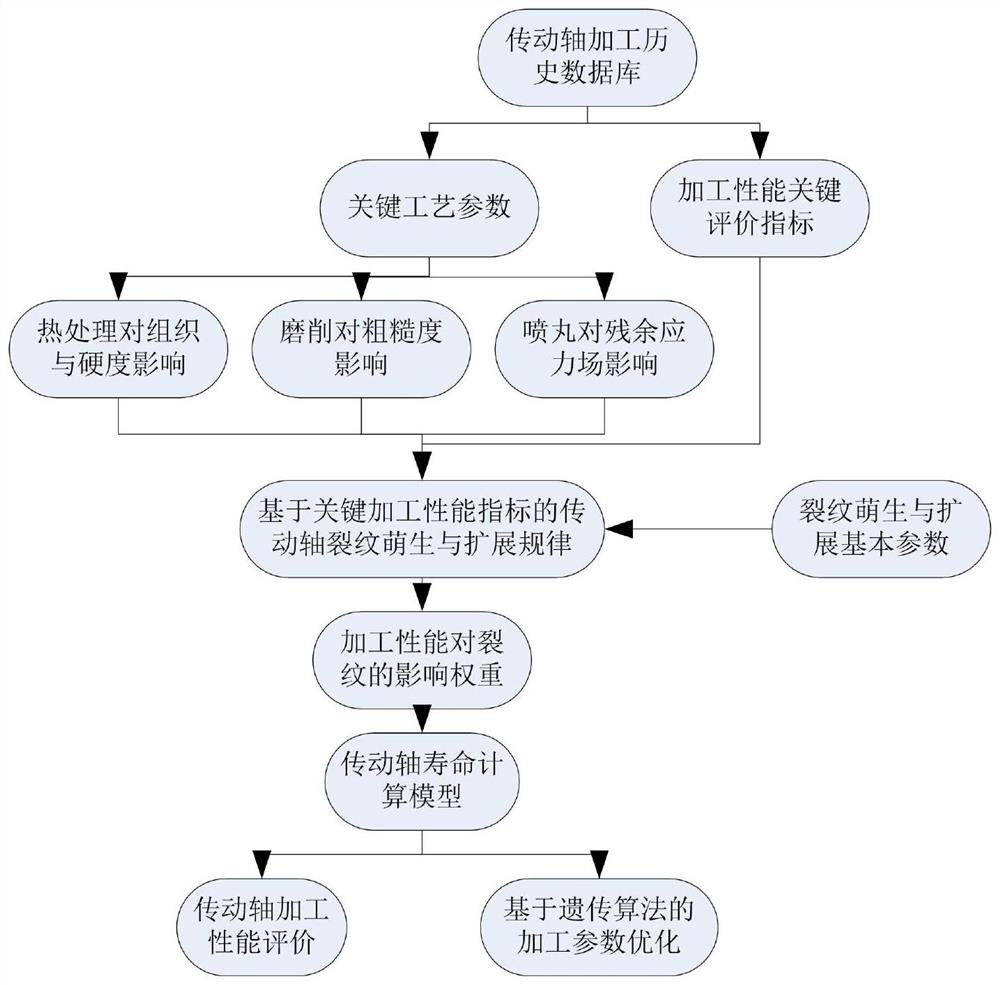

The present invention is an evaluation of transmission shaft processing performance and a control method based on key processes, including: 1. Extracting key process parameters and process performance key evaluation indicators in the transmission manufacturing process; 2. Obtaining key process control parameters based on simulation and test analysis The law of influence on its performance evaluation index; 3. On the basis of obtaining the relevant parameters of crack initiation and propagation of typical materials of the transmission shaft, study the influence law and influence weight of the processing performance evaluation index on the crack; 4. Evaluation of the processing performance of the transmission shaft The index is an intermediate variable, and the calculation model of the transmission shaft life is constructed; 5. Based on the genetic algorithm, the key process parameters of the transmission shaft are optimized. The present invention extracts relevant laws from historical simulation and test data, constructs the relationship between key process parameters, machined surface quality and cracks, can quickly predict and evaluate the surface processing performance, and can also optimize the process parameters according to the use requirements. Provide a theoretical basis for the high reliability design and manufacture of drive shafts.

Description

A drive shaft machining performance evaluation and control method based on key technology technical field The invention belongs to the long-life transmission element manufacturing field, be specifically related to a kind of transmission shaft machining performance evaluation and key Process control method. Background technique [0002] The transmission shaft is one of the key elements in the transmission systems such as heavy-duty vehicles and ships, and its working conditions are harsh and the load is complex. Future vehicles have higher and higher requirements for mobility, reliability and light weight. The requirements are also constantly increasing. How to ensure the service life of the drive shaft on the basis of light weight is the future design of the drive shaft An important issue facing manufacturing. The machined surface performance of the drive shaft directly determines its service life, and the surface roughness can be In order to directly affect the st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G06F30/27G06N3/12G06F119/04G06F119/08G06F119/16

CPCG06F30/27G06N3/126G06F2119/04G06F2119/08G06F2119/16Y02P90/02

Inventor 王延忠张炜余博

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com