LED drive circuit and method

An LED drive and circuit technology, applied in electrical components, energy-saving control technology, etc., can solve the problems of low output current accuracy, high cost, large output current and output current ripple, etc., to reduce system cost, high precision, Reduce the effect of external pins and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

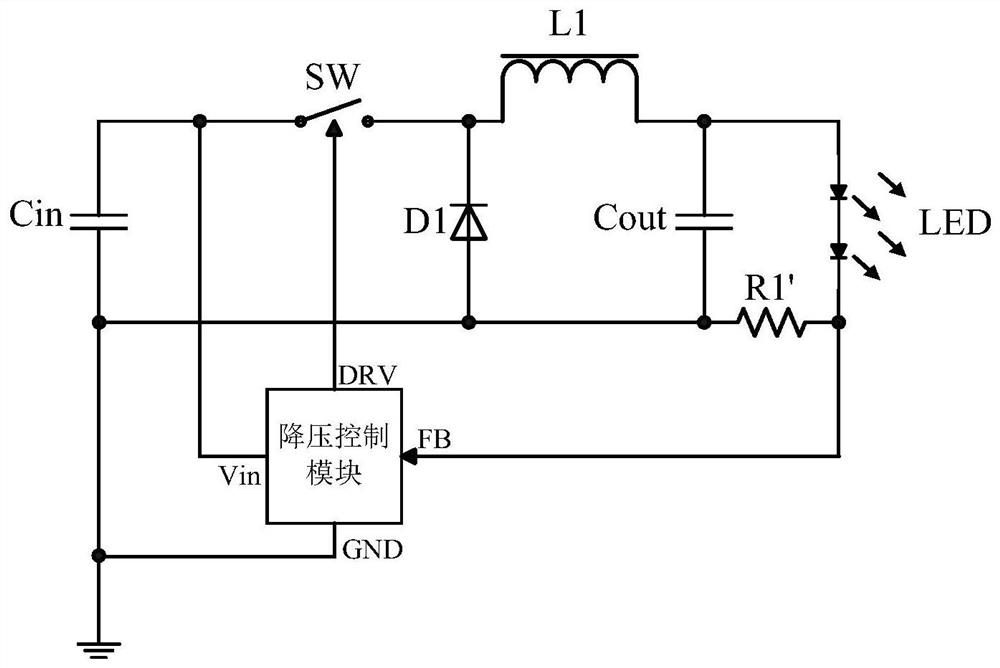

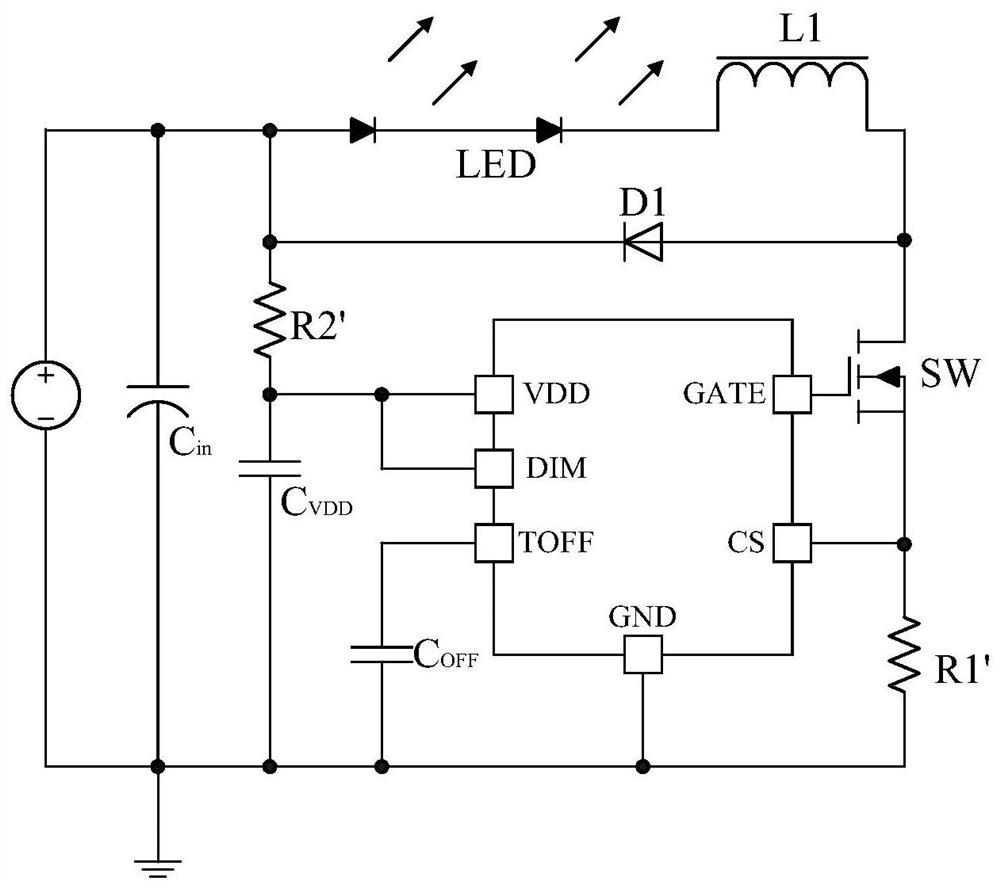

Problems solved by technology

Method used

Image

Examples

Embodiment 1

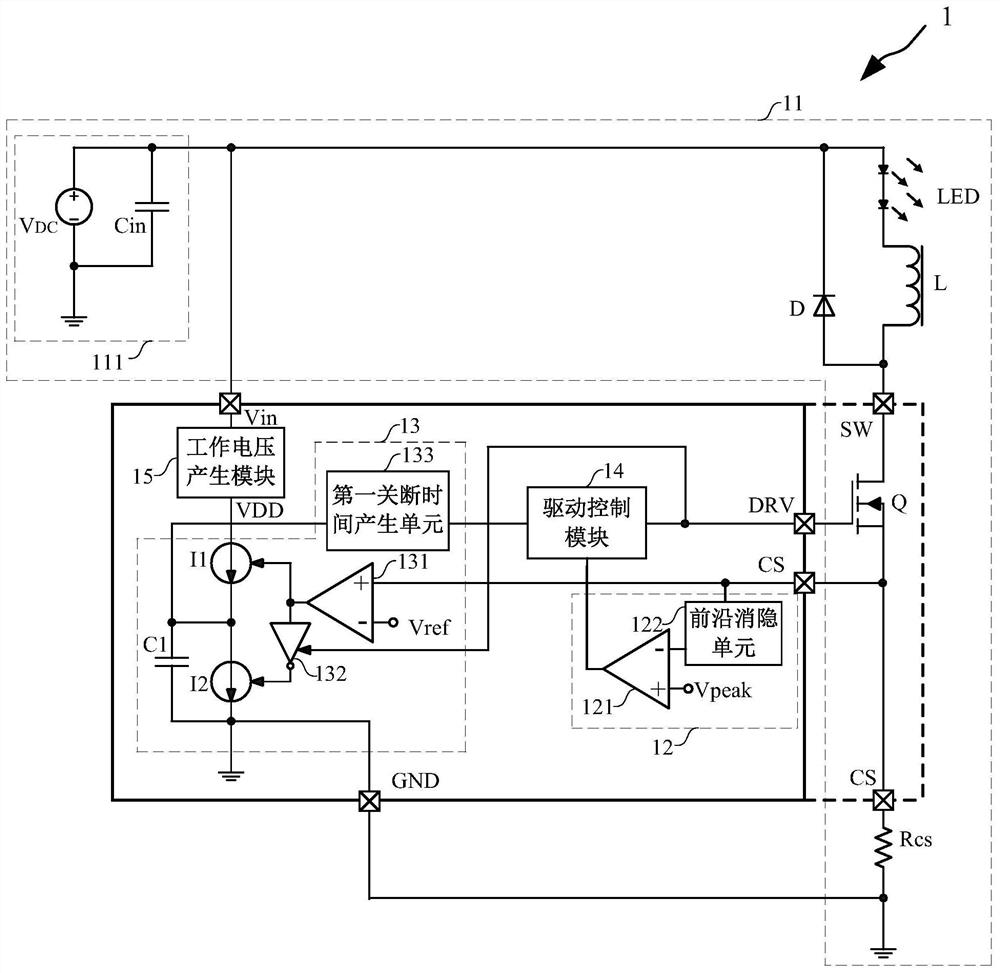

[0061] Such as image 3 As shown, this embodiment provides an LED driving circuit 1, and the LED driving circuit 1 includes:

[0062] Buck module 11, peak value control module 12, off-time control module 13 and drive control module 14.

[0063] Such as image 3 As shown, the step-down module 11 performs step-down processing on the input voltage to provide electric energy for the LED lamp segment.

[0064] Specifically, in this embodiment, the step-down module 11 includes a power input unit 111 , an LED segment LED, an inductor L, a diode D, a power switch tube Q and a sampling unit.

[0065] More specifically, in this embodiment, the power input unit 111 includes a DC power supply V DC and input capacitance Cin, the DC power supply V DC Obtained by methods including but not limited to AC power rectification. The power input unit 111 only needs to provide a DC input voltage, and the implementation is not limited to this embodiment, which will not be repeated here.

[0066...

Embodiment 2

[0097] Such as Figure 5 As shown, this embodiment provides an LED driving circuit, and the difference from Embodiment 1 lies in that the implementation of the off-time control module 13 is different.

[0098] Specifically, the off-time control module 13 includes a transconductance amplifier 134, a first switch S1, a second switch S2, a third switch S3, a first resistor R1, a second resistor R2, a second capacitor C2 and a second switch Off time generation unit 135.

[0099] More specifically, one end of the first switch S1 is connected to the sampling voltage Vcs, and the other end is connected to the non-inverting input terminal of the transconductance amplifier 134, and the non-inverting input terminal of the transconductance amplifier 134 is connected via the first The resistor R1 is grounded; one end of the second switch S2 is connected to the reference voltage Vref, and the other end is connected to the inverting input terminal of the transconductance amplifier 134, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com