Ultrathin pure titanium needle-shaped discharge electrode low-temperature plasma generator

A low-temperature plasma and discharge electrode technology, applied in the direction of plasma, electrical components, sanitary equipment for toilets, etc., can solve the problems of easy distortion and deformation, and achieve the effect of not easy to twist, stable and up to standard sterilization, and the installation process is artificially controllable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

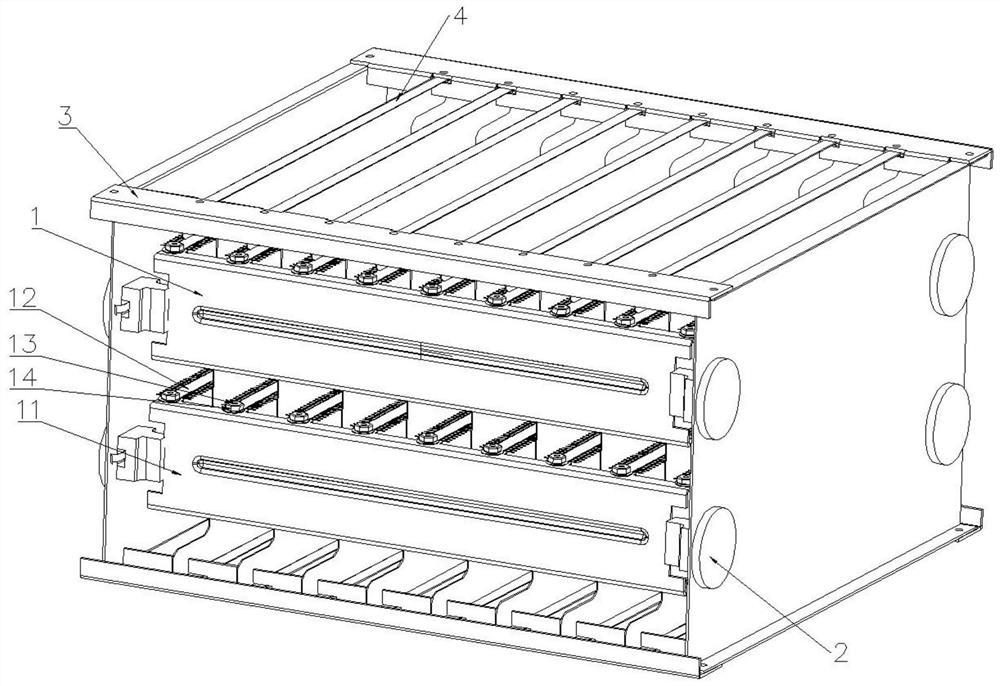

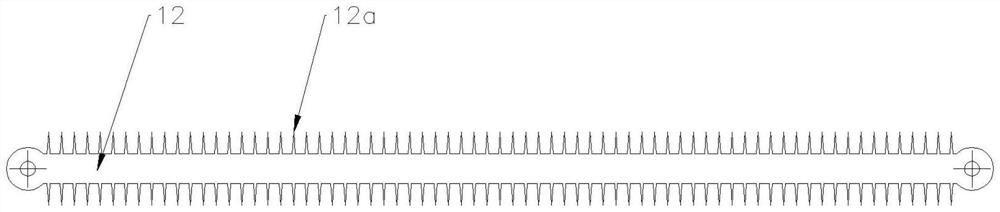

[0040] An ultra-thin pure titanium gold needle-shaped discharge electrode low-temperature plasma generator can solve the problem of easy distortion and deformation during the installation process of pure titanium gold positive electrode discharge needles in the prior art, such as Figure 1-Figure 9 As shown, specifically set to the following structure:

[0041] It includes an installation frame, a negative plate 4, an insulating connection assembly 2 and a set of positive discharge assemblies 1. Wherein, the installation frame includes two rectangular insulating block fixing plates 31 and four negative plate fixing frames 32, the two insulating block fixing plates 31 are horizontally parallel and vertically arranged, and the four negative electrode plate fixing frames 32 are arranged horizontally and horizontally. The insulating block fixing plate 31 is vertical, and the four negative plate fixing frames 32 are located at the four corners of the insulating block fixing plate 3...

Embodiment 2

[0048] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

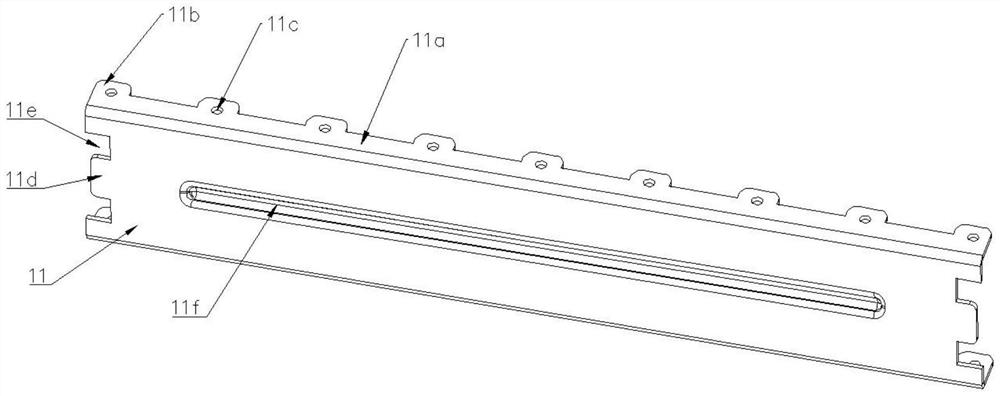

[0049] On the plate surface of the positive discharge pin plate 11, such as the outer plate surface is provided with at least one reinforcing rib 11f. The ribs 11f can be arranged vertically, horizontally or obliquely, preferably horizontally. When multiple reinforcement ribs 11f are provided, all reinforcement ribs 11f are parallel to each other. Setting reinforcing ribs 11f on the surface of the positive discharge pin plate fixing plate 11 can prevent it from being deformed under stress, thereby canceling the structure that uses support rods and nuts to stabilize between the positive electrode discharge pin plate fixing plates 11, so It can improve the structural stability of the positive discharge needle fixing plate 11 and also simplify the overall connection structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com