Traditional Chinese medicine pulverizer

A traditional Chinese medicine grinder and grinder technology, which is applied in grain processing and other directions, can solve the problems of reduced crushing efficiency, impact on crushing accuracy, and reduced efficiency, and achieve the effects of high processing accuracy, improved processing efficiency, and reduced heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

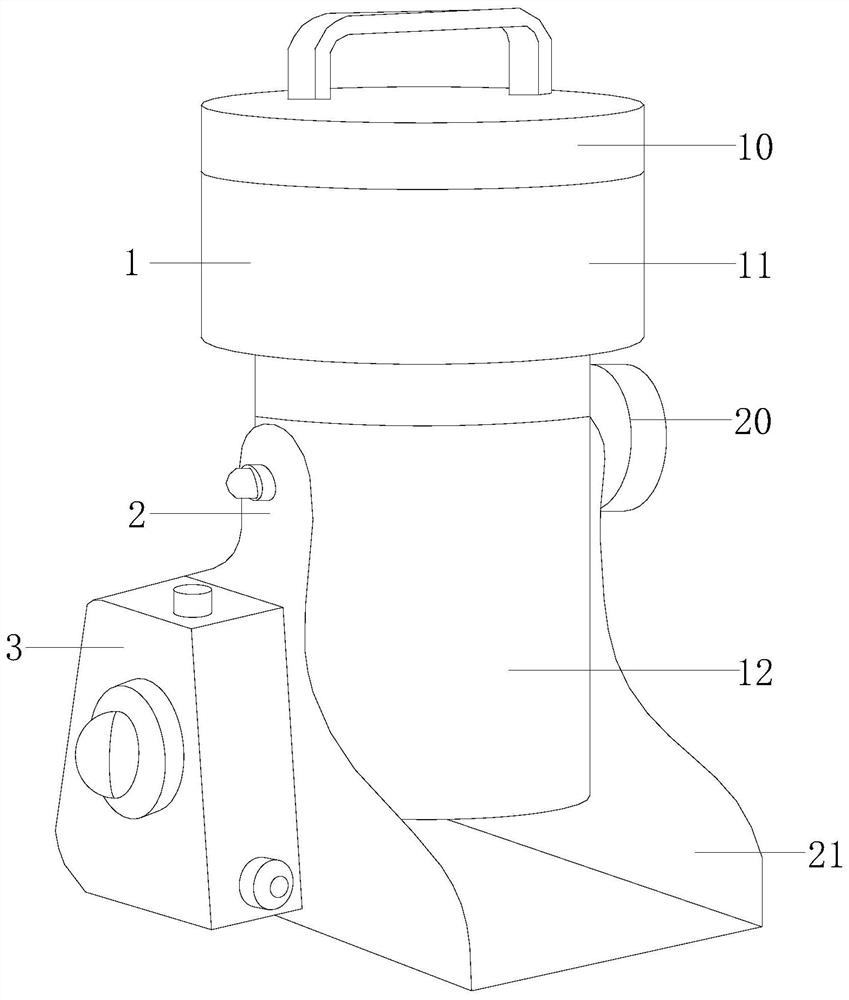

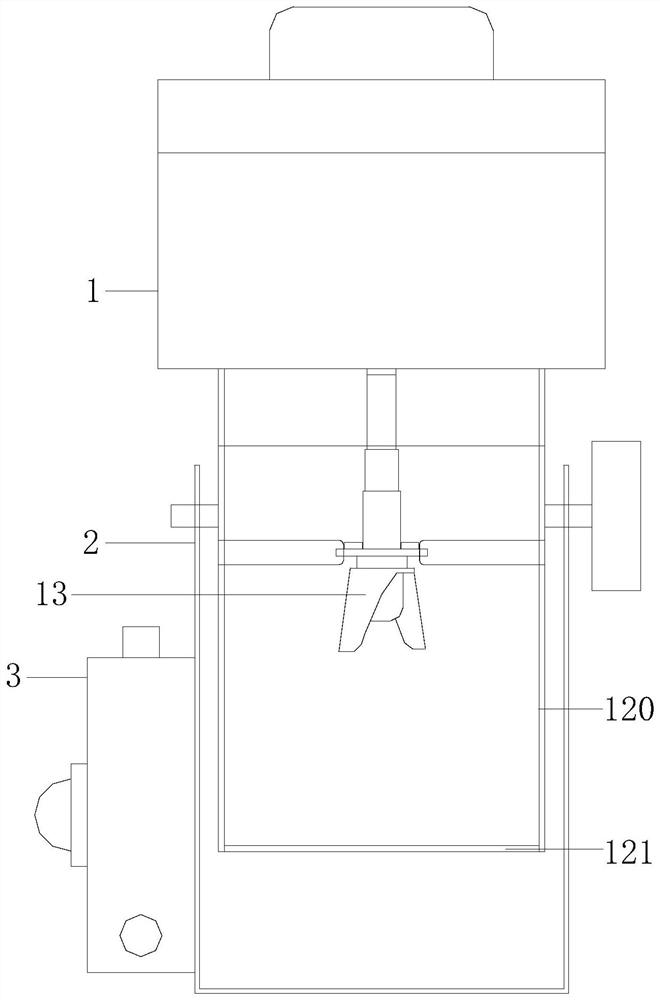

[0026] Example 1 see Figure 1-4 , the present invention provides a technical scheme of a traditional Chinese medicine pulverizer: its structure includes a pulverizer barrel 1, a bucket frame 2, and a control machine 3, the pulverizer barrel 1 is connected to the bucket frame 2, and the control machine 3 is locked in On the bucket frame 2, the pulverizer cylinder 1 is composed of a cylinder cover 10, a feeding upper cylinder 11, a cylinder body 12, and a crushing structure 13. The cylinder cover 10 cooperates with the feeding upper cylinder 11, and the feeding upper The cylinder 11 is installed and connected with the cylinder body 12, the crushing structure 13 is installed on the cylinder body 12, the bucket frame 2 includes the bucket frame rotating shaft 20, the bucket frame body 21, the bucket frame rotating shaft 20 is connected with the bucket frame body 21, the cylinder body The body 12 is installed and connected, and the rotating bucket frame shaft 20 is used to change ...

Embodiment 2

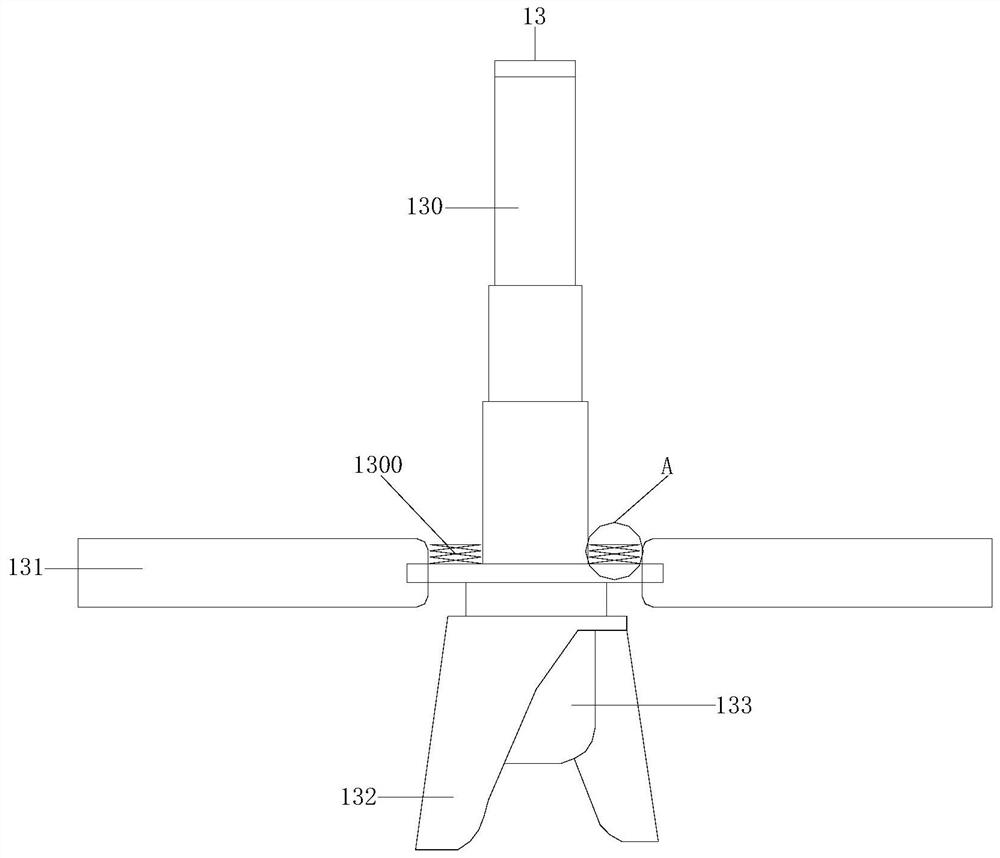

[0028] Example 2 see Figure 5-7 , the present invention provides a technical solution of a traditional Chinese medicine pulverizer: the structure of the crushing double knives 132 includes an inner rotary knife 1320 and an outer rotary knife 1321, and the crushing double knives 132 is a double-knife structure. The heat generated, the inner rotary knife 1320 and the outer rotary knife 1321 are installed on the biaxial motor 133, and the elastic material structure 1300 is used to bounce the material falling to the elastic material structure 1300 to avoid clogging. The material structure 1300 includes a material plate 50, a spring 51, and a lifting air cylinder 52. The material plate 50 is welded to the spring 51, and the material plate 50 is connected to the lifting air cylinder 52. The lifting air cylinder 52 includes a connecting block ring 520, a cylinder 521, air hole 522, the cylinder body 521 is installed and connected with the connecting block ring 520, the cylinder body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com