U-shaped aluminum enclosure machining device

A processing device, U-shaped technology, applied in the direction of feeding device, feeding device, positioning device, etc., can solve the problems of inconvenient processing and waste of manpower, and achieve the effects of saving manpower, improving processing efficiency and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

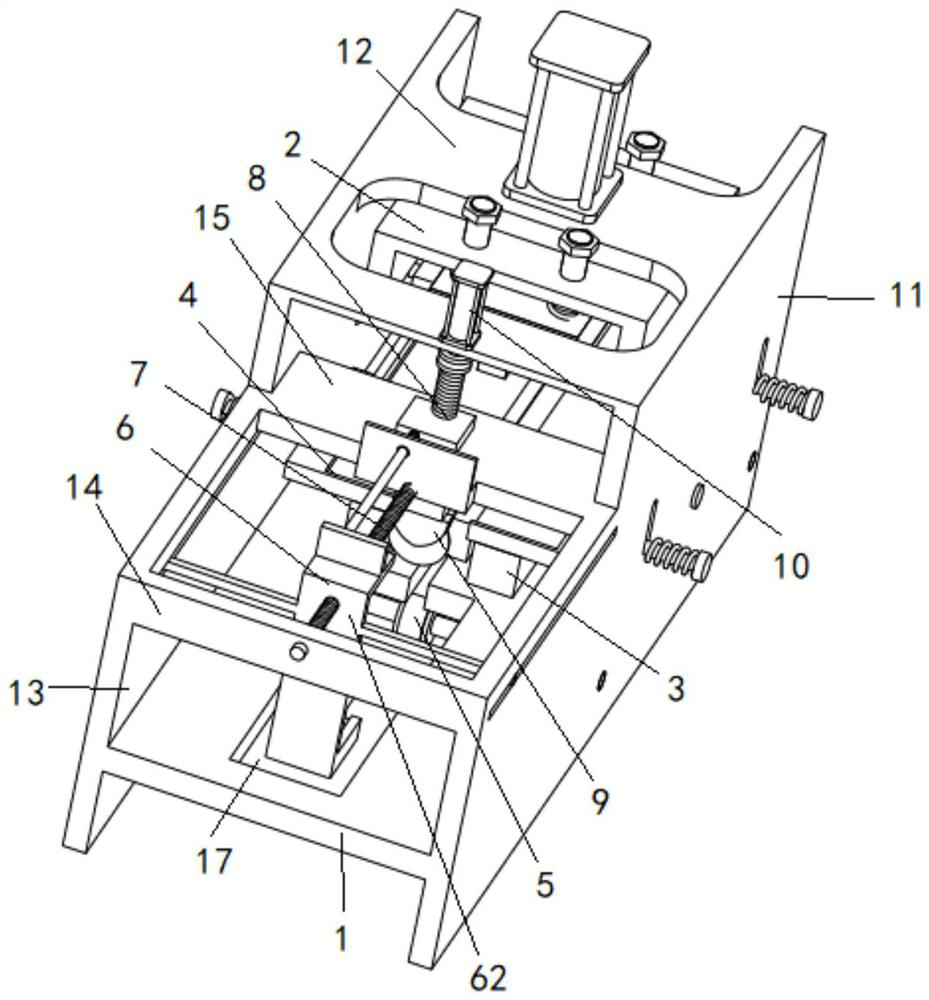

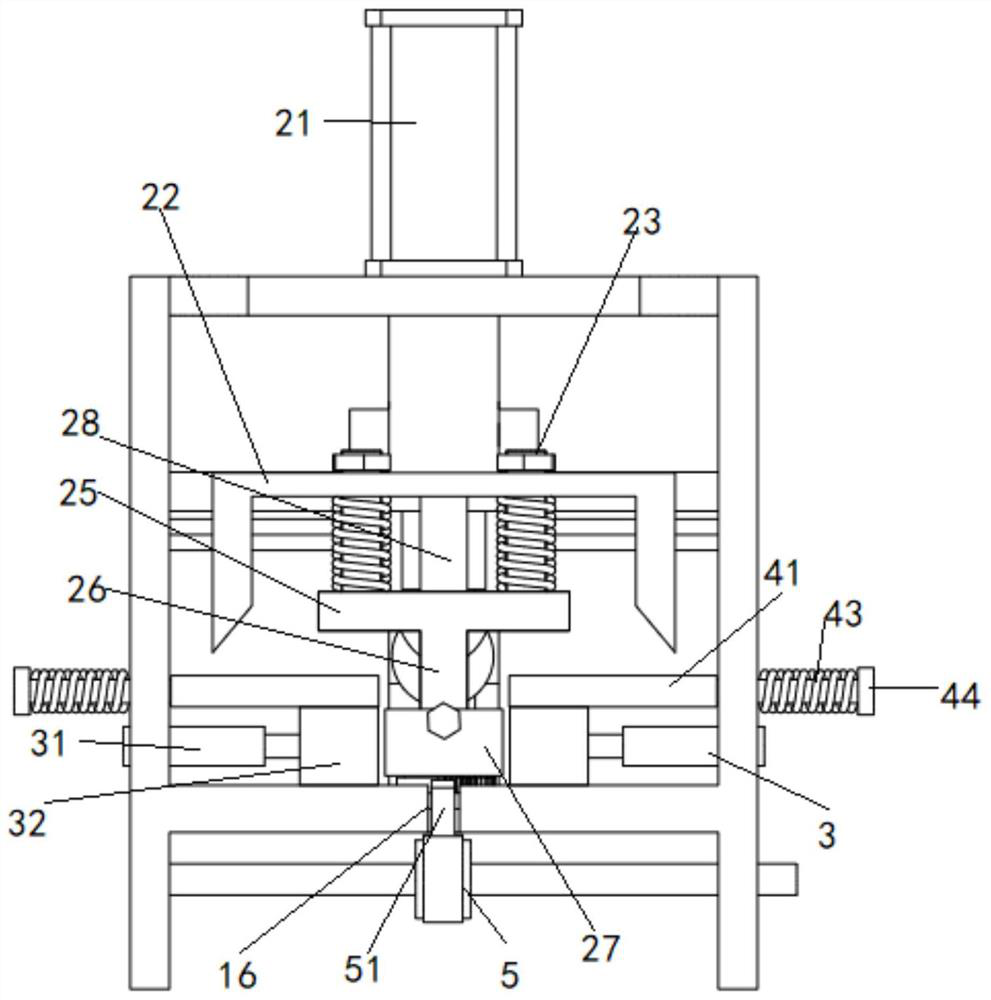

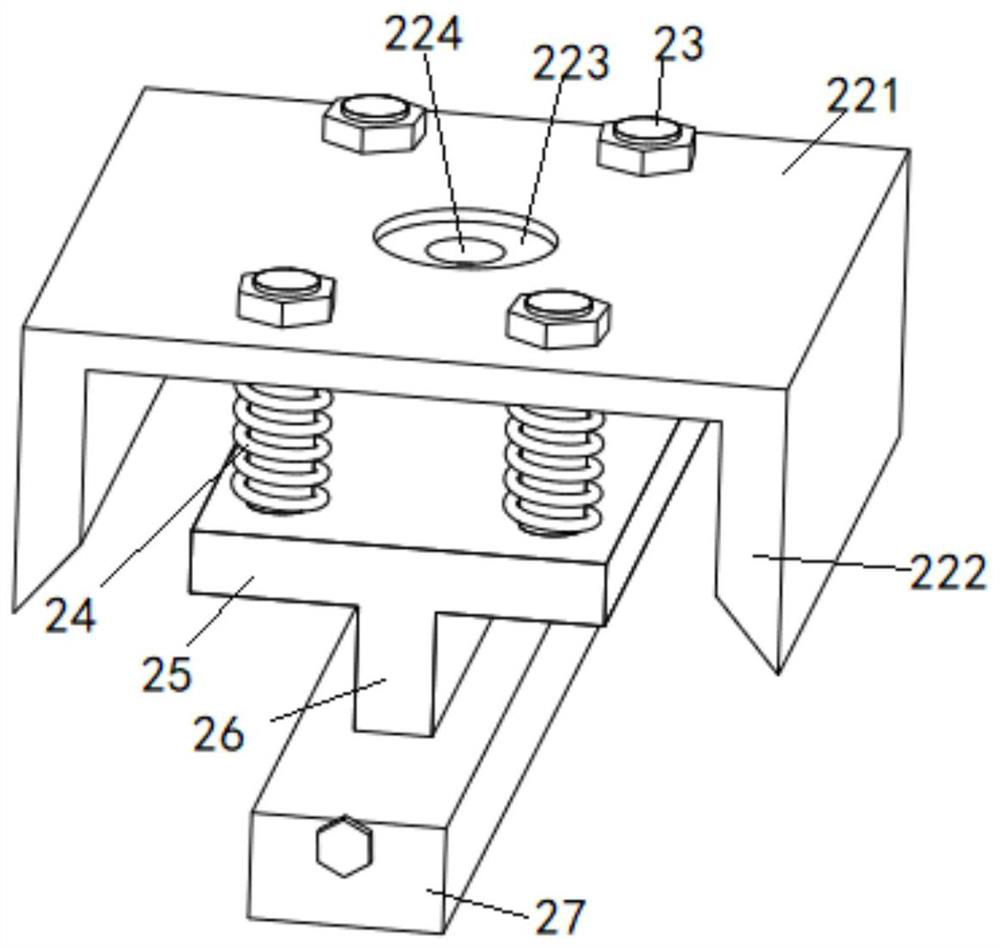

[0032] see Figure 1-7, describe in detail in conjunction with the following examples:

[0033] A U-shaped aluminum square pass processing device, including a processing machine tool 1, two oppositely arranged first support plates 11 are vertically fixed on the front and rear sides of the surface of the processing machine tool 1, and a first support plate 11 is installed in the middle of the surface of the first support plate 11. Fixed slats 12, the middle part of the surface of the first fixed slats 12 is equipped with an elastic stamping mechanism 2, while the two first support plates 11 are relatively equipped with a sizing mechanism 3, and the upper parts of the two sizing mechanisms 3 are equipped with a sizing limiter. Positioning mechanism 4, a transmission unloading mechanism 5 is installed at the bottom of the rear side of the processing machine tool 1; in the process of processing, the aluminum strip is placed on the two positioning and limiting mechanisms 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com