Building steel bar cutting device

A cutting device and technology for construction, applied in the field of construction, can solve the problems of difficult to guarantee cutting quality and efficiency, and difficult to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

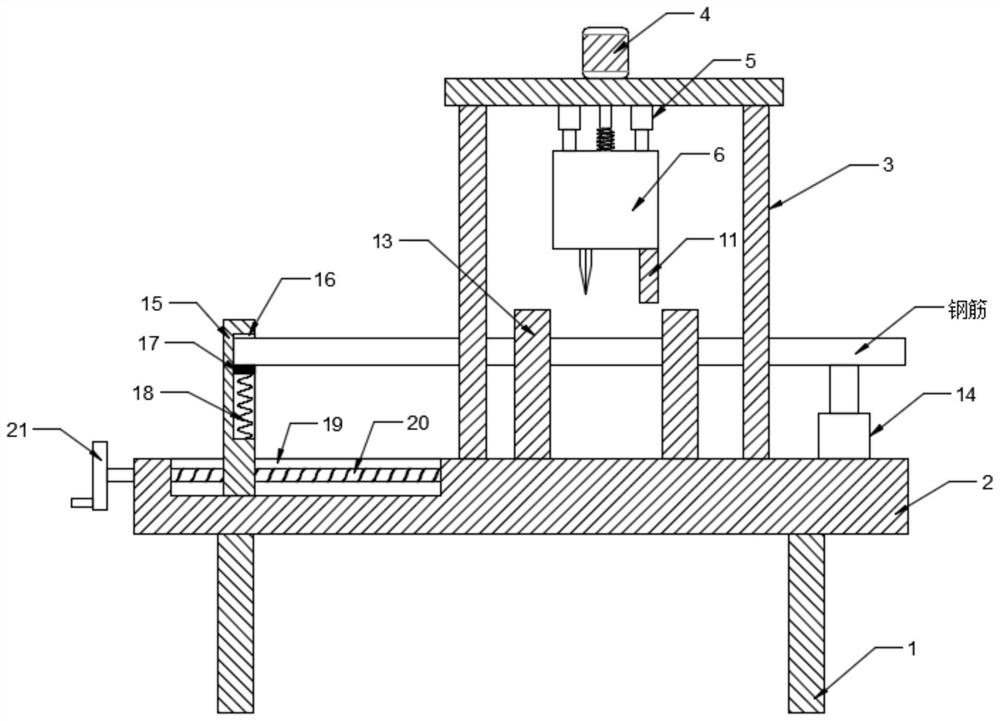

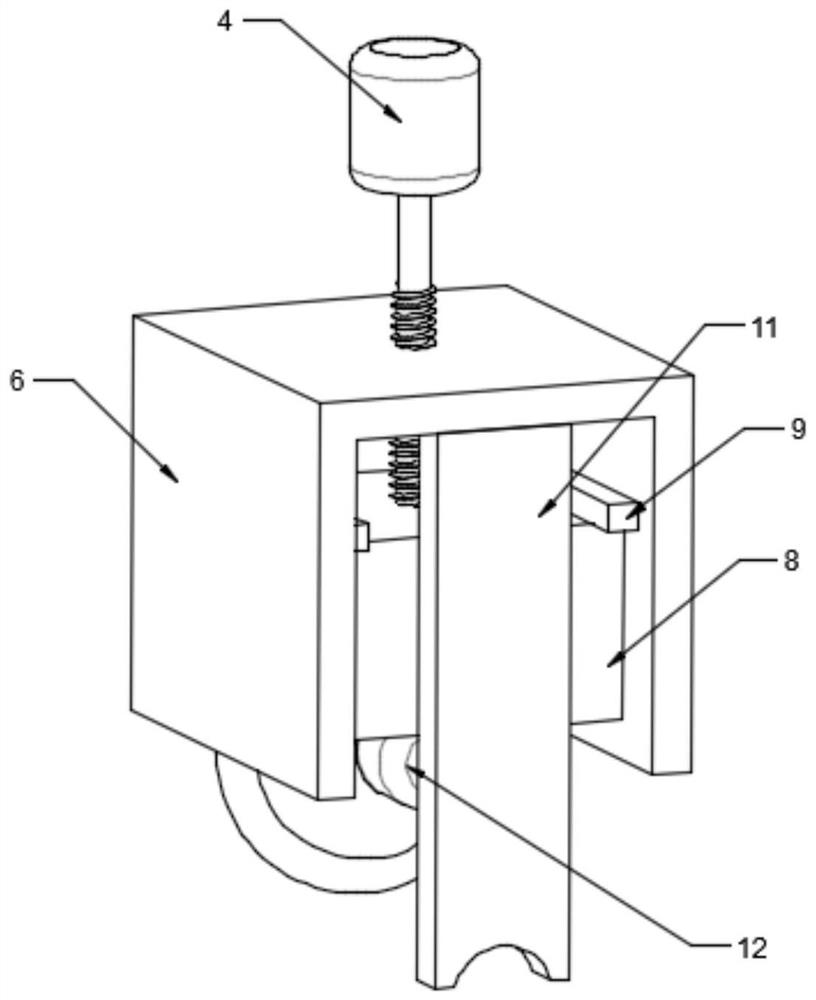

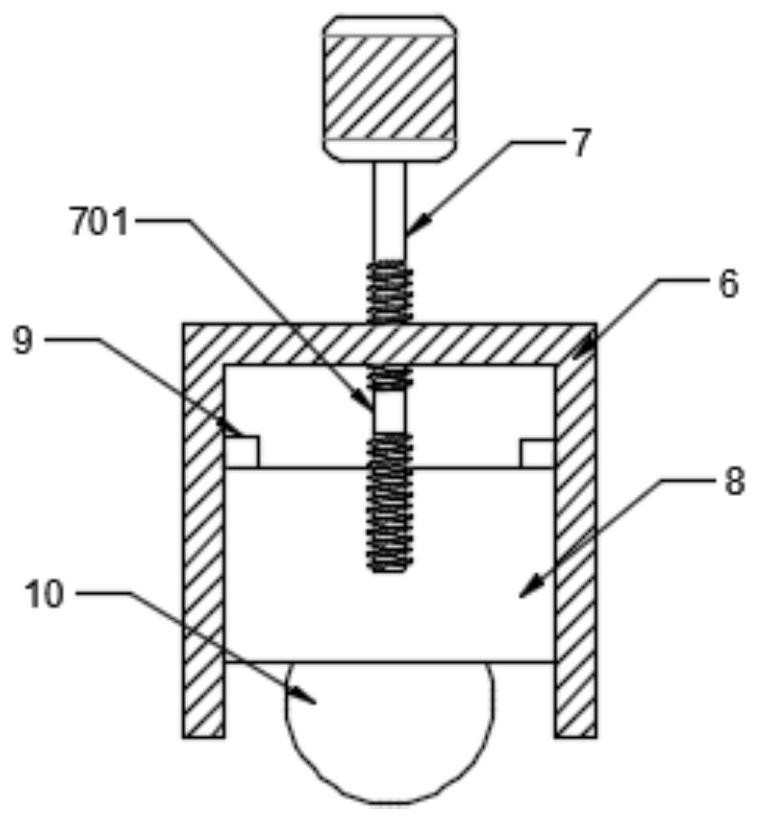

[0025] see Figure 1-5 , a steel bar cutting device for construction, comprising a column 1, a workbench 2 and a stand 3, the stand 3 is installed on the workbench 2, the workbench 2 is installed on the column 1, and the stand 3 is provided with a steel bar cutting Assemblies, the specific type of the steel bar cutting assembly is not limited. In this embodiment, preferably, the steel bar cutting assembly includes a drive motor 4, a telescopic rod 5, a lifting frame 6, a screw mandrel 7, a lifting block 8, a clip 9, a cutting Knife 10, pressing plate 11 and cutting motor 12, described driving motor 4 is fixedly installed on the stand 3 and the output end is driven and connected with screw mandrel 7, and the middle part of described screw mandrel 7 is provided with smooth section 701, and described lifting frame 6 passes through The telescopic rod 5 is installed on the stand 3 and is threadedly connected to the top of the smooth section 701. The lifting block 8 is slidably inst...

Embodiment 2

[0033] In order to improve the practicability, this embodiment is further improved on the basis of Embodiment 1. The improvement is that: the workbench 2 is provided with a cutting position adjustment assembly, and the specific type of the cutting position adjustment assembly is not limited. Among the examples, preferably, the cutting position adjustment assembly includes a sliding rod 15, a chute 19, a threaded rod 20 and a rotating disk 21, the chute 19 is provided on the workbench 2, and the threaded rod 20 is rotatably installed in the chute 19 and one end extends to The outside of the workbench 2 is fixedly connected with the turntable 21, the sliding rod 15 is slidably arranged in the chute 19 and is threadedly connected with the threaded rod 20, the surface of the workbench 2 outside the chute 19 is provided with a scale, and the sliding is adjusted through the turntable 21. The position of the bar 15 can determine the cutting position when one end of the steel bar touch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com