Chalcogenide glass aspheric lens machining tool and installation method thereof

A technology of aspheric lens and chalcogenide glass, which is applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as product deformation, achieve the effect of improving product quality and solving product deformation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In view of this, the core of the present invention is to provide a chalcogenide glass aspheric lens processing tool, which can solve the problem of product deformation caused by extrusion during the processing of the chalcogenide glass aspheric lens, thereby effectively improving the processing quality of the product.

[0033] Another core of the present invention is to provide a method for installing a chalcogenide glass aspheric lens processing tool.

[0034] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

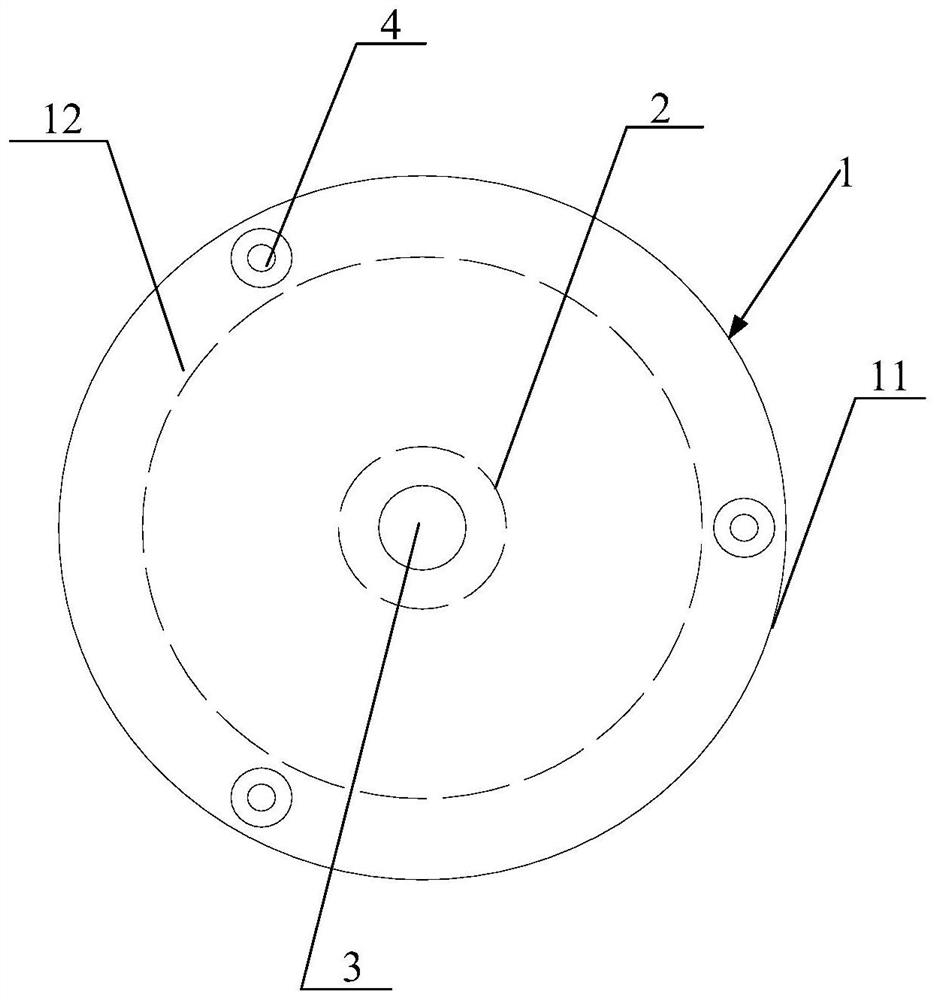

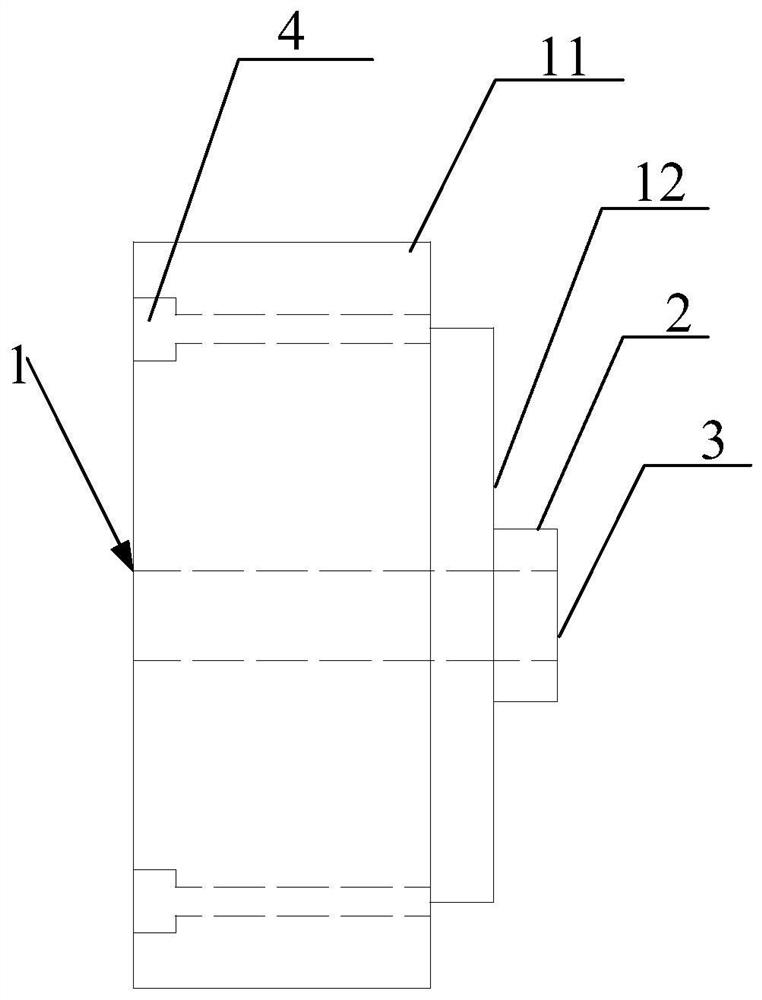

[0035] Please refer to Figure 1-Figure 2 , the chalcogenide glass aspheric lens processing tooling disclosed in the embodiment of the present invention includes: a tooling body 1 for absorbing a chalcogenide glass aspheric lens, and the center of the tooling body 1 is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com