Beam type bogie frame and beam type bogie

A bogie and beam-type technology, applied in the direction of mechanical conveyors, conveyors, motor vehicles, etc., can solve the problem of large size of the bogie, and achieve the effect of reducing the size of the bogie.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

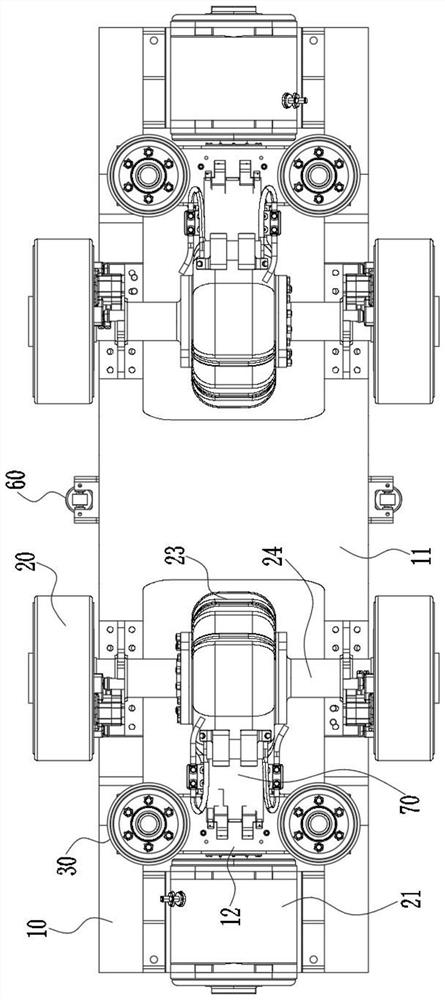

[0035] Such as Figure 4 As shown, urban underground logistics vehicles run in underground pipelines, and drainage ditches for discharging sewage or accumulated water are usually arranged in the pipelines. In the present invention, the top of the drainage ditch is used as the running surface 81 , and the sidewall of the drainage ditch is used as the guiding surface 82 .

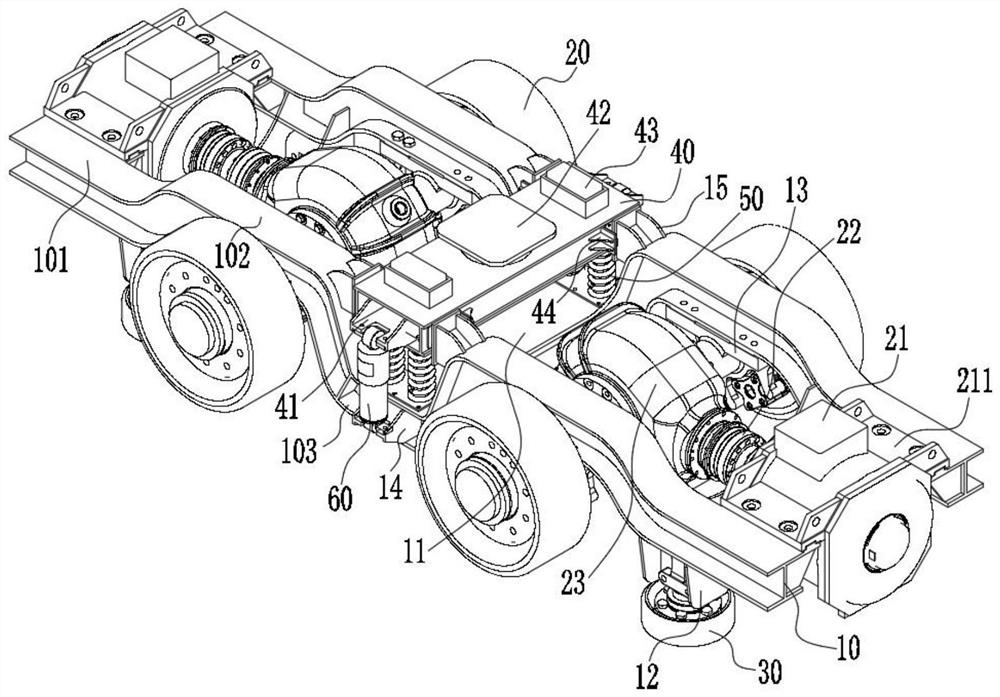

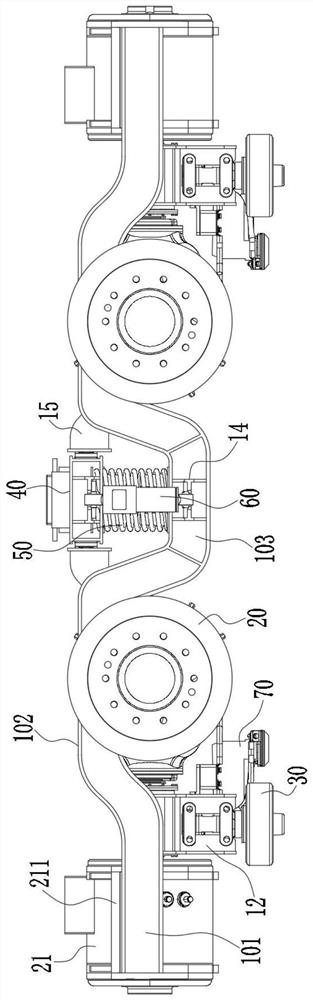

[0036] The invention provides a beam bogie frame, such as Figure 1 to Figure 3 As shown, a beam frame is included, and the beam frame includes longitudinal beams 10 , cross beams 11 and connecting beams 12 . Wherein, the longitudinal beam 10 includes a first straight section 101, a second straight section 102 and a third straight section 103, the middle part of the longitudinal beam 10 is the third straight section 103, and the two ends of the longitudinal beam 10 are the first flat sections. Straight sections 101 , the first straight sections 101 at both ends are arranged symmetrically with respect to the...

Embodiment 2

[0042] The present invention also provides a beam bogie, such as Figure 1 to Figure 3 As shown, it includes the beam bogie frame, traveling wheels 20 and guide wheels 30 in the above embodiments. A wheel shaft 24 is connected between the running wheel frame 13 at the bottom of the second straight section 102 between the two longitudinal beams 10 through a bearing, and the wheel shaft 24 is connected with the running wheel 20 after extending outward. As a power bogie, the beam bogie frame is also connected with a driving motor 21 for driving the traveling wheels 20 to walk. The driving motor 21 is connected to a gear box 23 through a coupling 22, and the driving motor 21 drives the gear box 23 to run. The box 23 drives the traveling wheel 20 to travel through the wheel shaft 24 .

[0043] Such as Figure 1 to Figure 3 As shown, specifically, two supporting plates 211 are connected to both sides of the driving motor 21 by welding or bolting, and the supporting plates 211 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com