FOSB full-automatic bag opening and bagging device

A bagging device, fully automatic technology, applied in the field of FOSB automatic bag supporting and bagging device, can solve the problems of low production efficiency and low degree of automation, and achieve the effect of improving bagging efficiency and the overall structure is simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

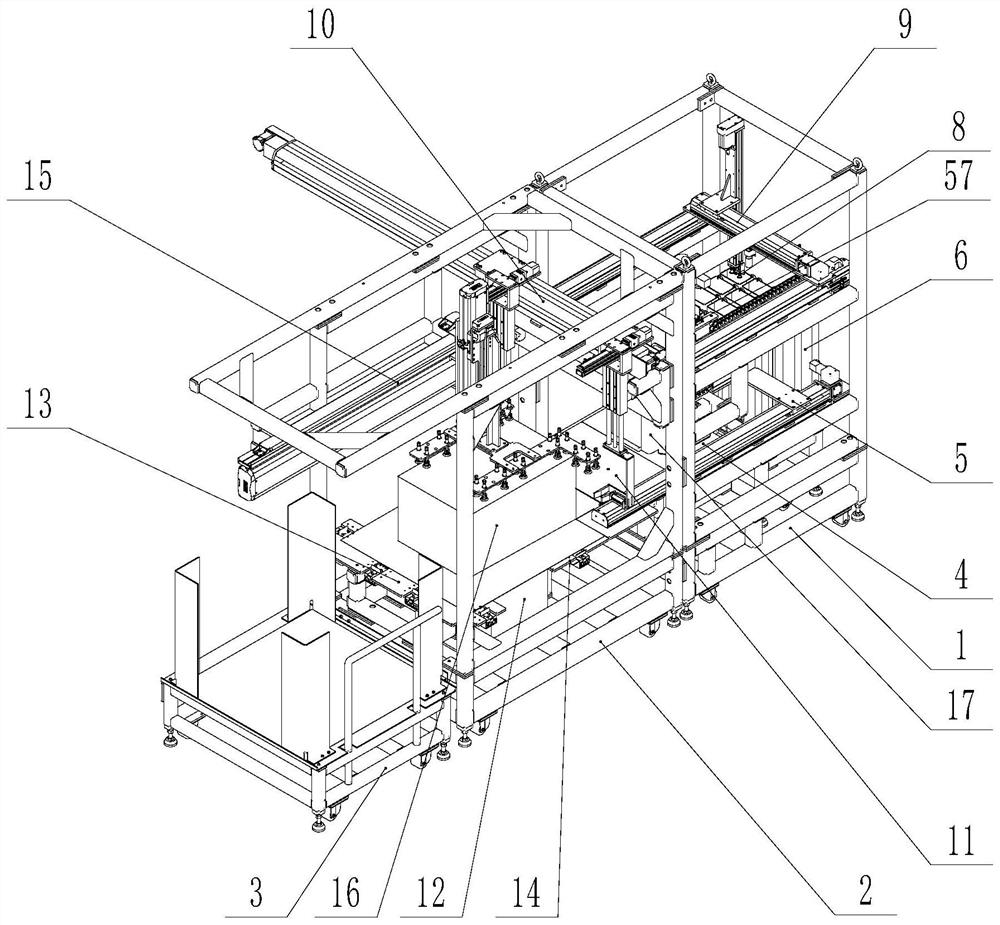

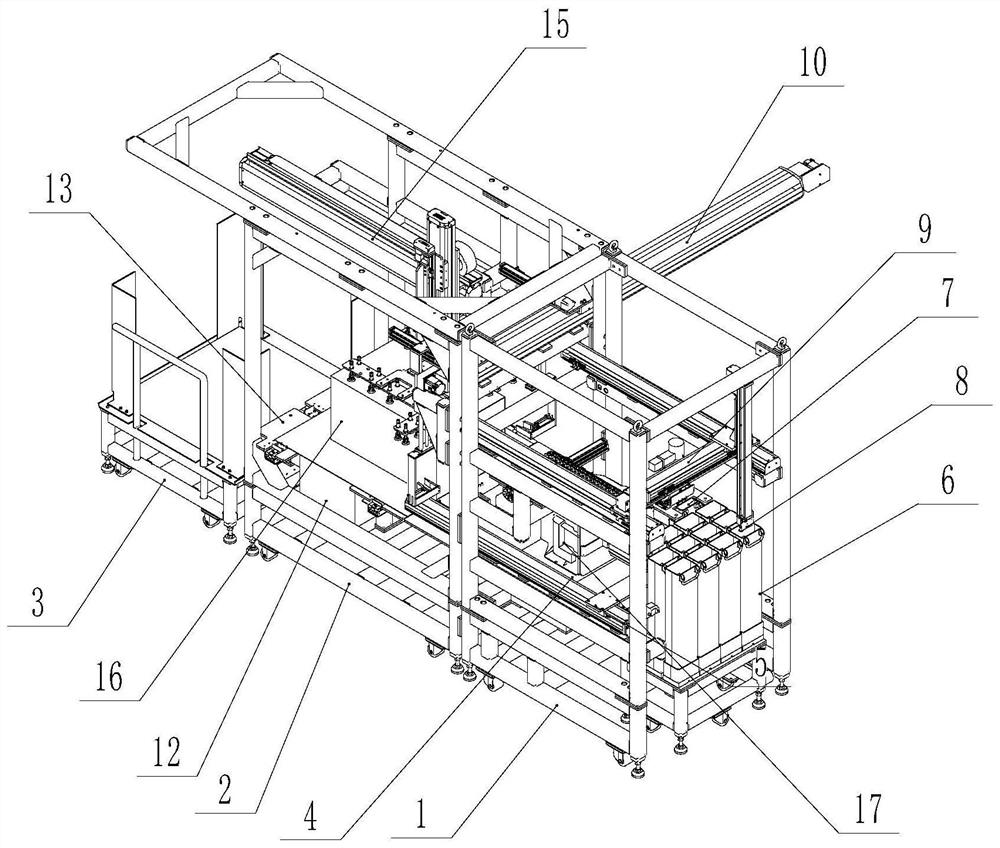

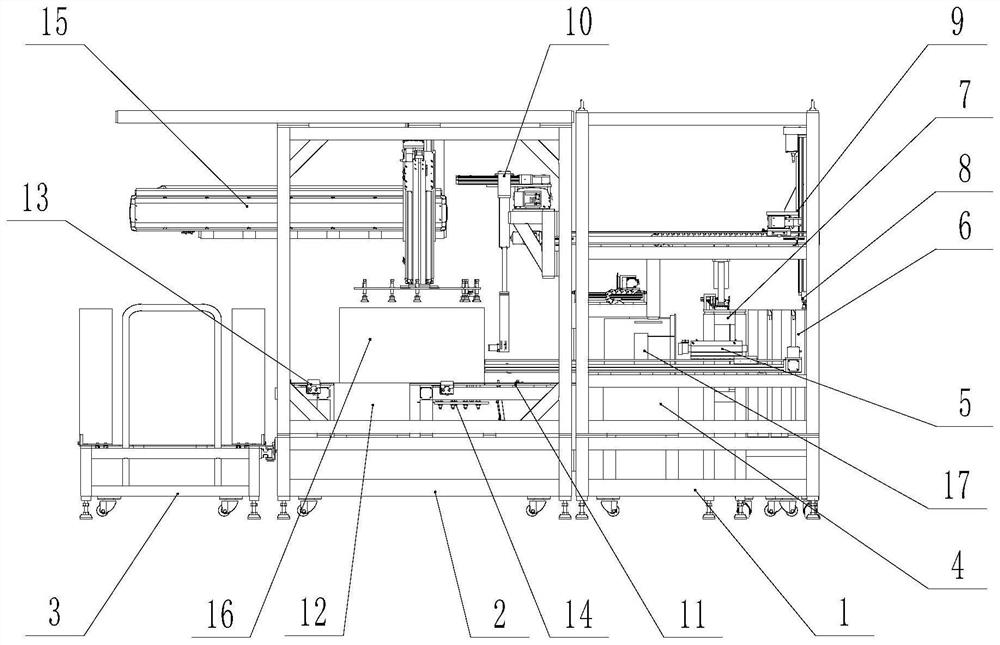

[0053] The present invention will be further described below in conjunction with accompanying drawing:

[0054] Such as Figure 1-18 As shown in the figure, a FOSB automatic bagging and bagging device includes a feeding frame 1, a bag supporting frame 2, a packaging bag storage frame 3, a FOSB placing platform 4, a FOSB horizontal pushing device 5, and a desiccant silo 6. Humidity card silo 7, grabbing device 8, handling device 9, transfer support device 10, bag pressure transition device 11, packaging conveyor belt 12, bag tail positioning device 13, bottom suction cup device 14 and upper bag moving and suction bag device 15,

[0055] Among them, the discharging rack 1, the FOSB placing table 4, the FOSB horizontal pushing device 5, the desiccant silo 6, the humidity card silo 7, the grabbing device 8 and the handling device 9 constitute the discharging station of the device. Place the humidity card and dryer, and push the FOSB to the bagging station are all carried out at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com