Feeding equipment for non-woven fabric production

A technology for non-woven fabrics and equipment, applied in the field of feeding equipment for non-woven fabric production, can solve the problems of waste of raw materials, affecting the quality of textiles, prone to coke bottom, etc., to achieve faster melting rate, better use effect, and avoid coke. bottom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

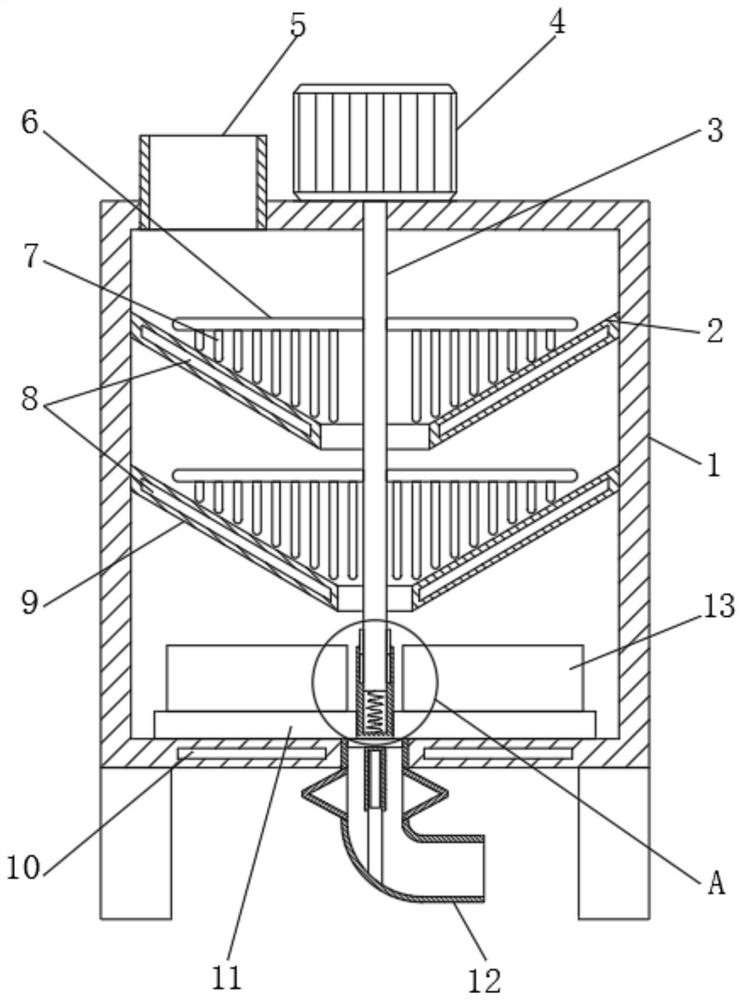

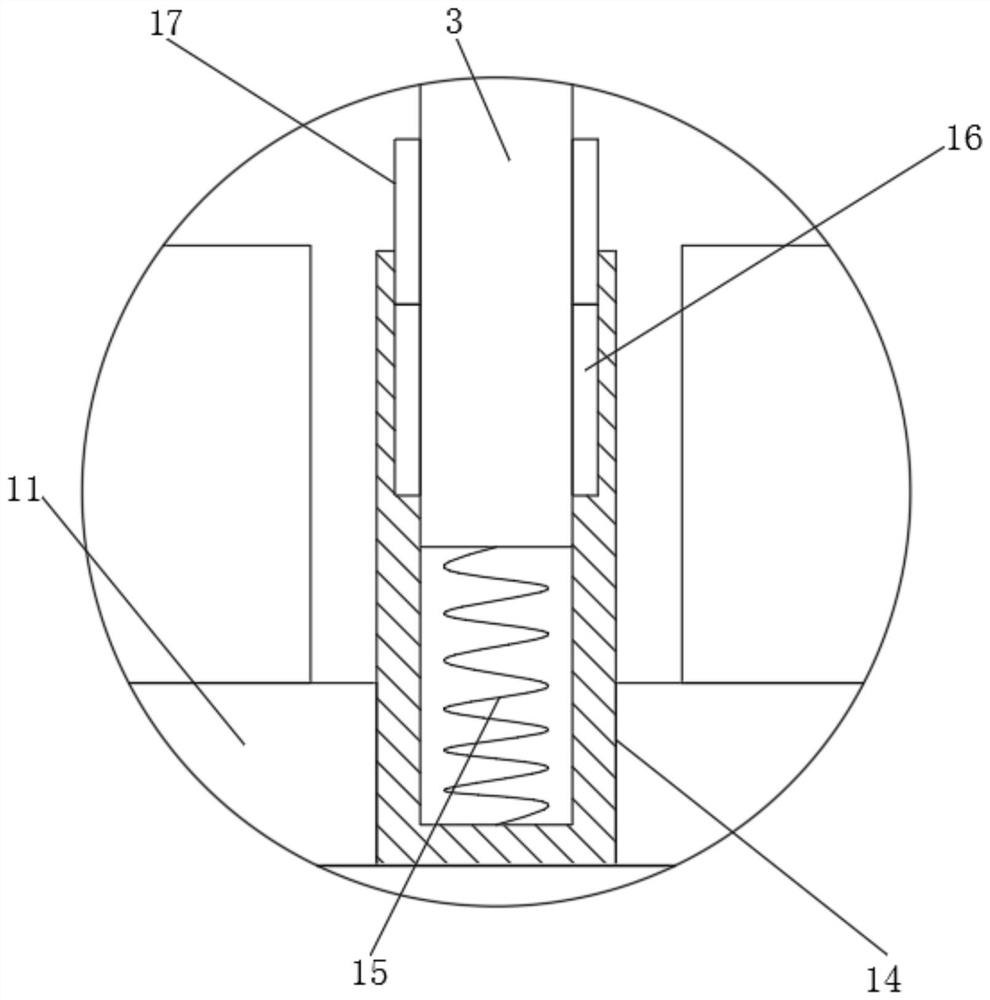

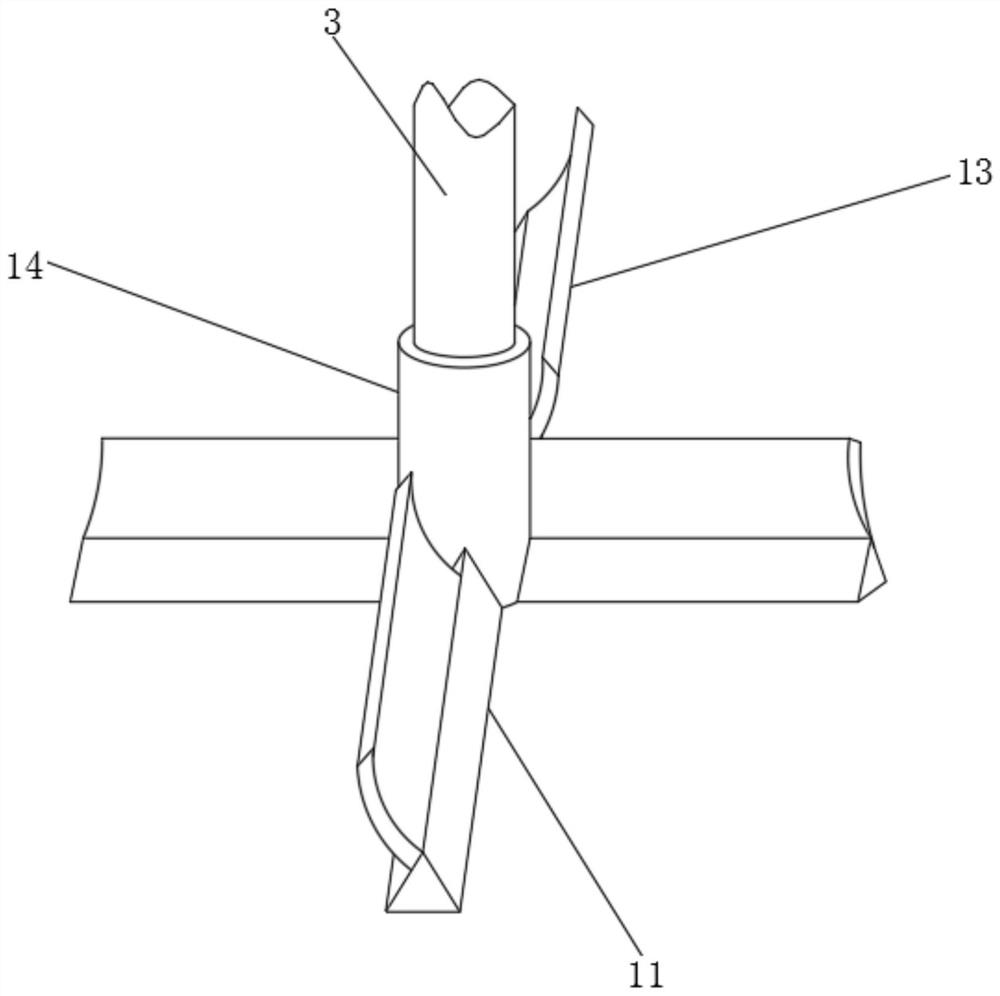

[0031] refer to Figure 1-4 , a feeding device for non-woven fabric production, comprising a tank body 1, the inner wall of the tank body 1 is respectively fixedly connected with a first lower hopper 2 and a second lower hopper 9, and the first lower hopper 2 and the second lower hopper 9 Both are provided with a first heating plate 8, the top outer wall of the tank body 1 is fixedly connected with a motor 4, and one end of the output shaft of the motor 4 is provided with a rotating shaft 3, and the rotating shaft 3 is provided with a stirring mechanism, and the top outer wall of the tank body 1 is provided with an inlet The barrel 5 and one end of the rotating shaft 3 are provided with an anti-scorch bottom mechanism, the bottom outer wall of the tank body 1 is provided with a discharge mechanism, and the bottom inner wall of the tank body 1 is provided with a second heating plate 10 .

[0032] The stirring mechanism includes a crossbar 6 and a rotating rod 7 , the crossbar 6...

Embodiment 2

[0040] refer to Figure 5-6 , a feeding device for non-woven fabric production. Compared with Embodiment 1, this embodiment also includes that the inner walls on both sides of the feeding cylinder 5 are connected with dust shields 22 through the rotation of the ear seats, and the two sides of the feeding cylinder 5 The outer walls are all provided with slide holes, and the inner walls of the slide holes are slidably connected with an arc rod 23, one end of the arc rod 23 is fixedly connected with the bottom outer wall of the dust shield 22, and the outer wall of the arc rod 23 is sleeved with a second spring 24 .

[0041] Working principle: when using, when the raw material is introduced through the feeding cylinder 5, due to the gravity of the raw material, the dust shield 22 rotates and compresses the second spring 24 on the arc rod 23. When the raw material falls, the second spring 24 Resetting the dust shield 22 can block the feeding cylinder 5 again, preventing dust from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com