Robots for large cargo transport

A technology of cargo transportation and robots, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems affecting the production efficiency of coal mine construction, etc., and achieve the effect of facilitating remote control, solving limitations, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

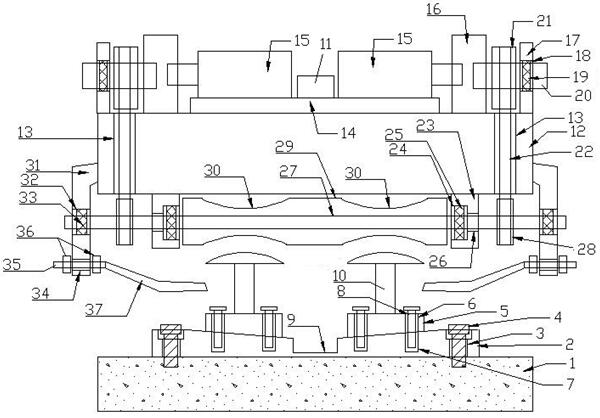

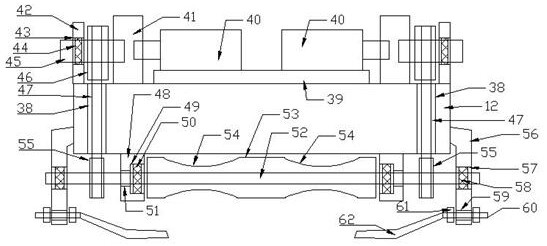

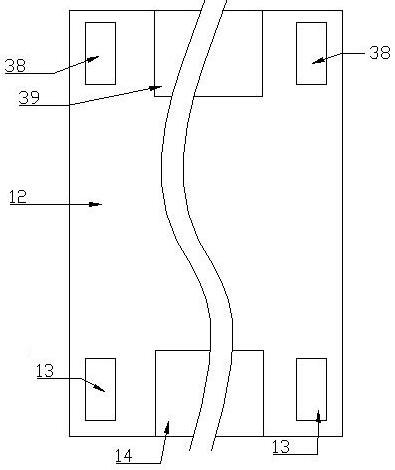

[0022] Such as figure 1 , figure 2 and image 3 The shown robot suitable for large-scale cargo transportation is composed of a bottom support assembly and a cargo delivery assembly used in conjunction with the bottom support assembly; the bottom support assembly includes a base 1 and a support set on the base 1 Plate 2, and the support plate positioning holes 3 symmetrically arranged in both ends of the support plate 2, and the support plate locking bolts 4 that fix the support plate 2 on the base 1 through the support plate positioning holes 3, and symmetrically arranged on the support plate Several sets of auxiliary support plate positioning holes 7 located between the two ends of the plate 2 and between the support plate positioning holes 3, and a set of guide rail limit plates 5 symmetrically arranged on the support plate 2, and a set of guide rail limit plates 5 respectively arranged on the support plate 2. Several groups of guide rail limit plate through holes 6 used ...

Embodiment 2

[0024] Such as figure 1 , figure 2 and image 3 The shown robot suitable for large-scale cargo transportation is composed of a bottom support assembly and a cargo delivery assembly used in conjunction with the bottom support assembly; the bottom support assembly includes a base 1 and a support set on the base 1 Plate 2, and the support plate positioning holes 3 symmetrically arranged in both ends of the support plate 2, and the support plate locking bolts 4 that fix the support plate 2 on the base 1 through the support plate positioning holes 3, and symmetrically arranged on the support plate Several sets of auxiliary support plate positioning holes 7 located between the two ends of the plate 2 and between the support plate positioning holes 3, and a set of guide rail limit plates 5 symmetrically arranged on the support plate 2, and a set of guide rail limit plates 5 respectively arranged on the support plate 2. Several groups of guide rail limit plate through holes 6 used in...

Embodiment 3

[0026] Such as figure 1 , figure 2 and image 3 The shown robot suitable for large-scale cargo transportation is composed of a bottom support assembly and a cargo delivery assembly used in conjunction with the bottom support assembly; the bottom support assembly includes a base 1 and a support set on the base 1 Plate 2, and the support plate positioning holes 3 symmetrically arranged in both ends of the support plate 2, and the support plate locking bolts 4 that fix the support plate 2 on the base 1 through the support plate positioning holes 3, and symmetrically arranged on the support plate Several sets of auxiliary support plate positioning holes 7 located between the two ends of the plate 2 and between the support plate positioning holes 3, and a set of guide rail limit plates 5 symmetrically arranged on the support plate 2, and a set of guide rail limit plates 5 respectively arranged on the support plate 2. Several groups of guide rail limit plate through holes 6 used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com