Construction Technology of Cement Mixing Pile on Weak Ground in Plateau Alpine Swamp Area

A technology for cement mixing piles and swampy areas, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as slow footage, unsatisfactory construction quality, and easy overturning of construction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

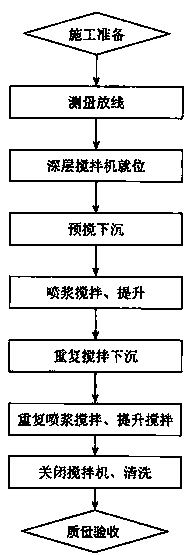

[0017] The specific construction method is as follows:

[0018] 1. After testing and testing, groundwater is acidic water, and the volume expansion of concrete materials is mainly due to the C in cement. 3 A plays a chemical role, and tests have shown that C in grade 42.5 sulfate and chloride corrosion-resistant cement 3 The content of A is less than 5%. The project finally decided to use 42.5-grade sulfate and chloride corrosion-resistant cement as the construction raw material. During the construction process, the reaction between the sulfate soft soil environment and water was minimal, and the sulfuric acid was greatly reduced. Damage of saline soil to concrete. The use of 42.5-grade sulfate- and chloride-resistant cement can make the technical indicators of cement mixing piles in saline soil areas reach the standard.

[0019] 2. The on-site construction site is a swamp area, and the thickness of the silt is more than 3m. In order to ensure the cement mixing

[0020] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com