Quick-drying high-solid polyurea coating, its preparation method and application

A high-solid, polyurea technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., to achieve the effects of reducing construction time, excellent mechanical properties, and improving construction production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

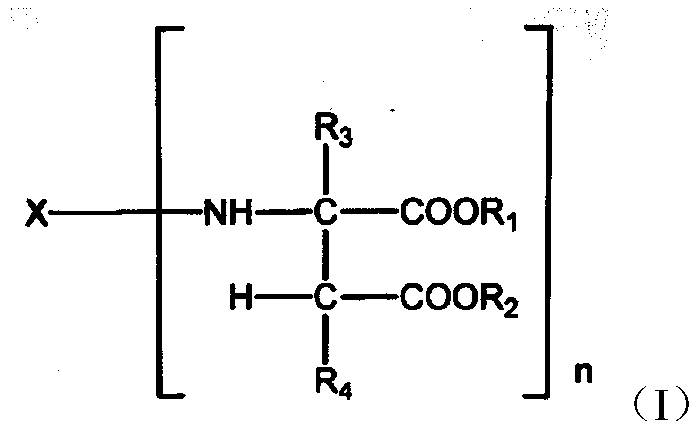

Method used

Image

Examples

preparation example Construction

[0068] According to a typical embodiment of the present invention, a method for preparing a quick-drying high-solid polyurea coating is provided. The preparation method comprises the following steps: 1) adding 5 to 15 parts of composite antirust pigment, 10 to 45 parts of pigment and filler, and 1 to 5 parts of auxiliary agent and part of the solvent, grind until the fineness reaches 20 microns, and the temperature reaches 60-65°C; add 0.1-1.5 parts of the adhesion promoter and the remaining part of the solvent, and mix well to obtain component A; 2) 15-35 2 parts of isocyanate curing agent is component B; 3) before use, mix component A and component B to prepare a quick-drying high-solid polyurea coating.

[0069] Preferably, a solvent is used to adjust the viscosity of component A in step 1).

[0070] According to a typical embodiment of the present invention, according to the construction technology, the solid volume of the fast-drying high-solid polyurea coating of the pr...

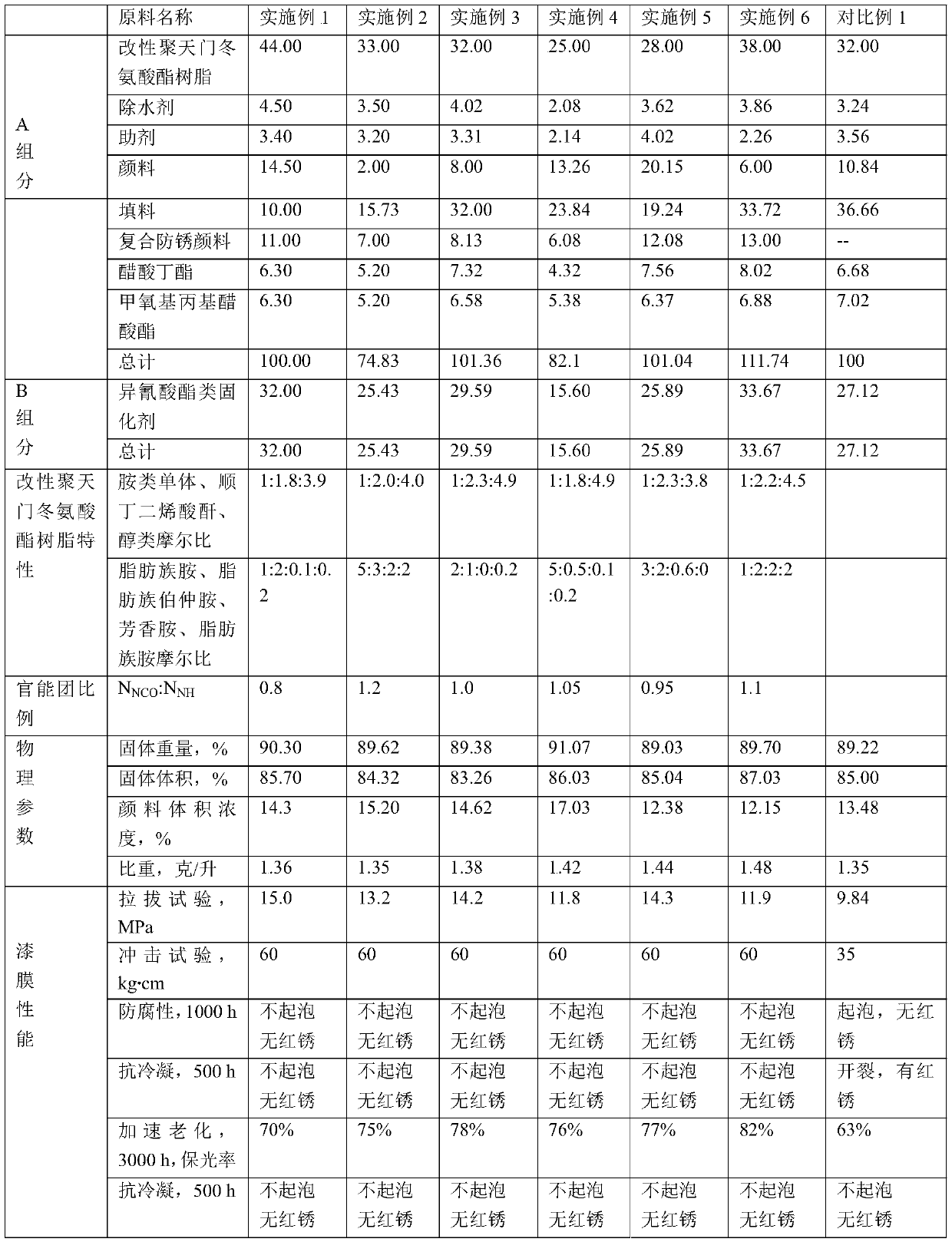

Embodiment 1 to 6

[0095] The quick-drying high-solid polyurea coating in embodiment 1 to 6 among the present invention is realized by following production technology:

[0096] Component A: Add modified polyaspartic acid ester resin, add water remover, rheological agent, wetting and dispersing agent, leveling agent, anti-rust pigment and pigment filler during stirring; grind until the fineness reaches 20 microns, temperature Reach 60~65℃; add light stabilizer, UV absorber, adhesion promoter and butyl acetate, mix well; adjust viscosity with methoxypropyl acetate.

[0097] B component: polyisocyanate.

[0098] Before use, mix component A and component B according to the weight ratio shown in Table 1 to prepare the quick-drying high-solid polyurea coating of the present invention.

[0099] The compositions, physical parameters and film properties of the quick-drying high-solid polyurea coatings provided in Examples 1 to 6 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com