Environment-friendly electroplating wastewater treatment equipment

A technology for electroplating wastewater and treatment equipment, applied in metallurgical wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as deficiencies, shrinking the internal volume of chemical reaction pools, excessive drugs, etc., to improve treatment efficiency. Wastewater treatment effect, effect of reducing internal volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

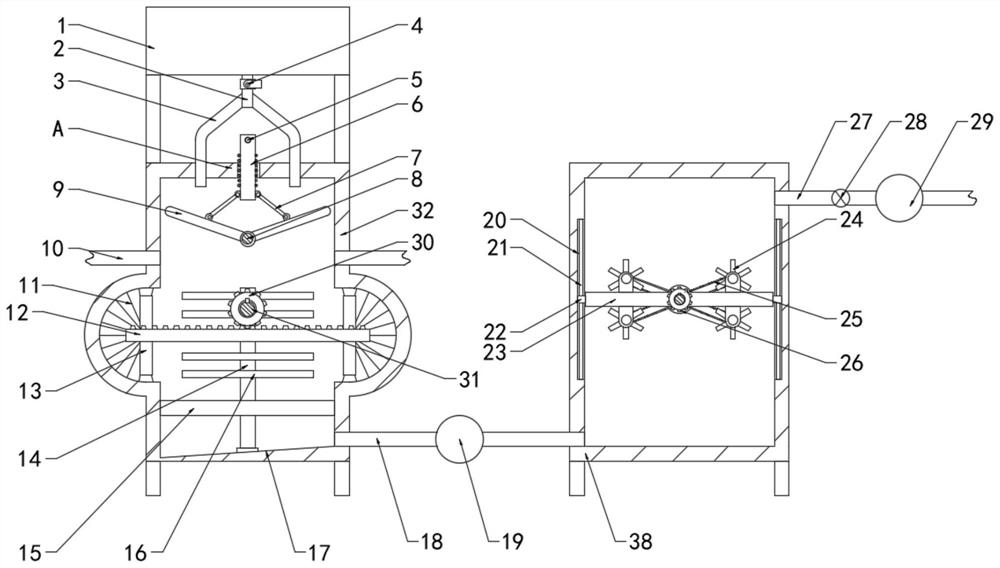

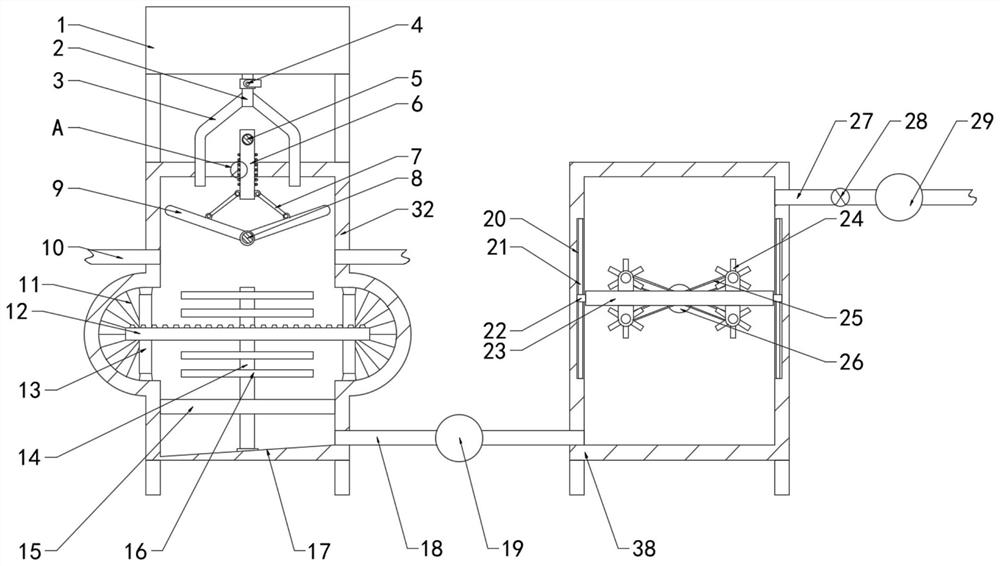

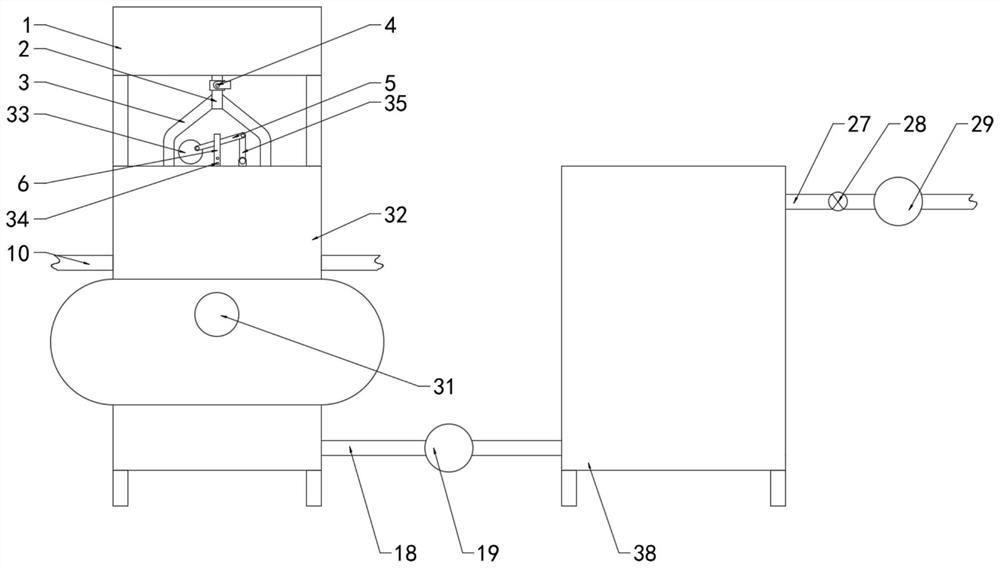

[0050] see Figure 1-9, an environment-friendly electroplating wastewater treatment equipment, comprising a waste liquid treatment tank 32 and a sedimentation tank 38, the waste liquid treatment tank 32 is connected with water inlet pipes 10 on both sides, and the waste liquid treatment tank 32 and the sedimentation tank 38 are connected through a connecting pipe 18 , one side of the settling tank 38 is communicated with an outlet pipe 27, and the connecting pipe 18 and the outlet pipe 27 are respectively equipped with a first delivery pump 19 and a second delivery pump 29. At first, the electroplating wastewater enters the waste liquid treatment tank 32 through the inlet pipe 10 After mixing and stirring with the liquid medicine, the electroplating wastewater is treated for the first time by chemical treatment, so that the toxic substances in it are converted into non-toxic substances or sediments with greatly reduced toxicity. The waste liquid after primary treatment is pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com