A kind of thermal insulation spray glue cotton and its glue spray device

A technology for spraying glue cotton and glue, which is applied in spraying devices, textiles and papermaking, cleaning methods and utensils, etc. The effect of reliable delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

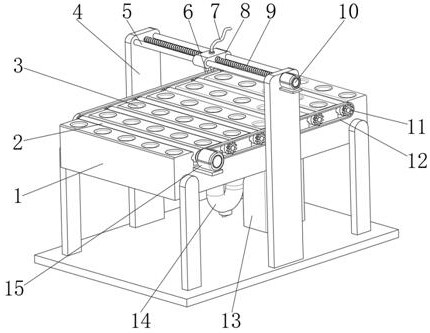

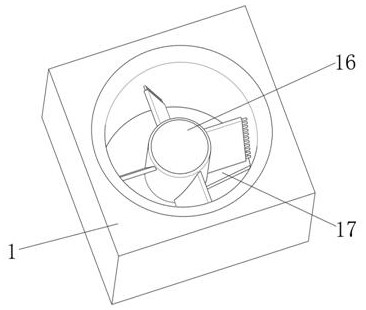

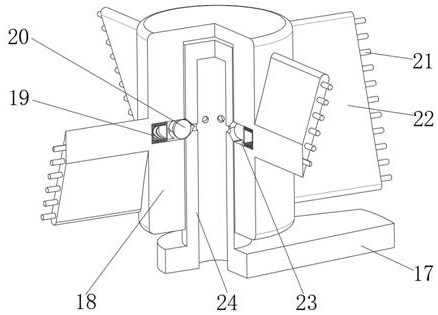

[0041] A kind of glue spraying device of warm glue spraying cotton, as Figure 1-6 As shown, it includes a negative pressure table 1, and a glue spraying mechanism is installed above the negative pressure table 1 through a support frame 4. The glue spraying mechanism includes a moving seat 8 and a glue spraying head 6, and the glue spraying heads 6 are equidistantly installed On the outer wall of the bottom of the movable seat 8, the outer wall of the top of the movable seat 8 is provided with a rubber delivery pipe 7 communicating with the glue spray head 6. The other end of the rubber delivery pipe 7 is connected with a glue supply device, and the outer wall of one side of the support frame 4 is fixed by screws. The translation motor 10 that controls the lateral movement of the glue spray head 6, the two inner walls of the support frame 4 are equipped with a translation stud 9 through the bearing seat, and one end of the translation stud 9 is connected to the output end of th...

Embodiment 2

[0054] A thermal spray cotton, such as Figure 1-7 As shown, when the thermal spray cotton is produced, the above-mentioned glue spraying device is used for production in the glue spraying link.

[0055] In order to ensure the heat preservation effect; the raw materials of the heat preservation spray-bonded cotton are 4080 low-melting point polyester fibers, polyester staple fibers and ultrafine fibers; wherein the percentage of ultrafine fibers accounts for 25% to 45% of the total mass of the raw materials, or even 30%.

[0056] In order to improve product quality; such as Figure 7As shown, when the heat-preserving glue-sprayed cotton is glue-sprayed, the suction force in the U-shaped tube 14 is controlled between 1.5-3.5Mpa, even 2Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com