A construction method of combined formwork

A construction method and combined technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, formwork/formwork components, etc., which can solve the problem of less turnover times and long mold matching cycle , not easy to repair and other problems, to achieve the effect of convenient adjustment and disassembly, reduce construction cost, and ensure pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

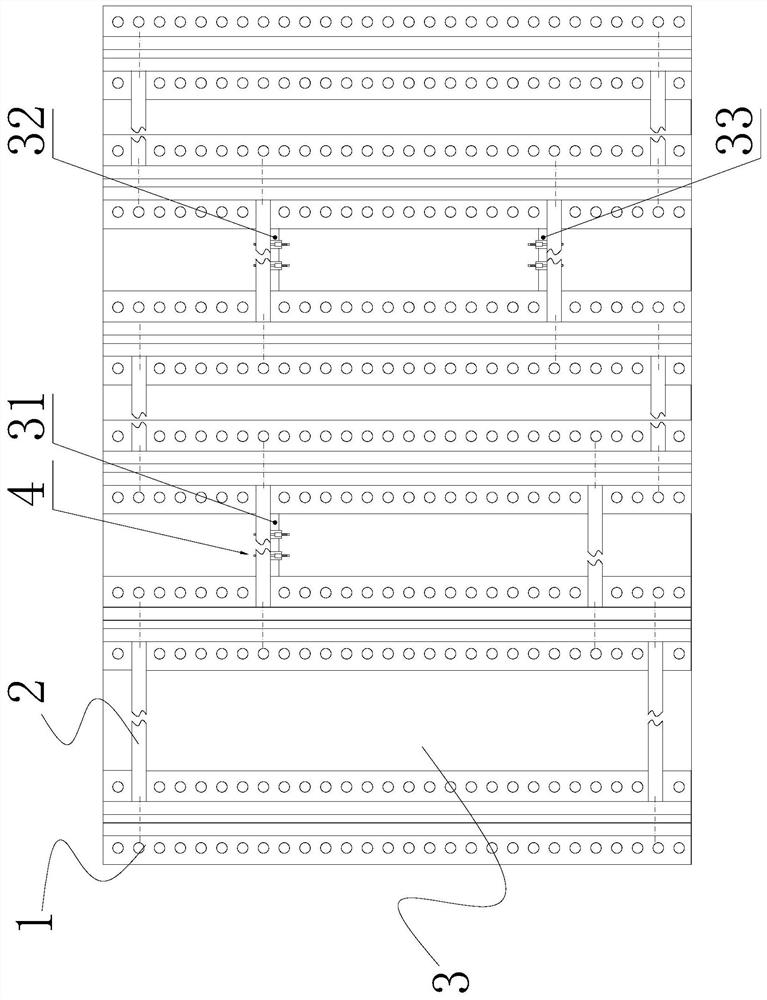

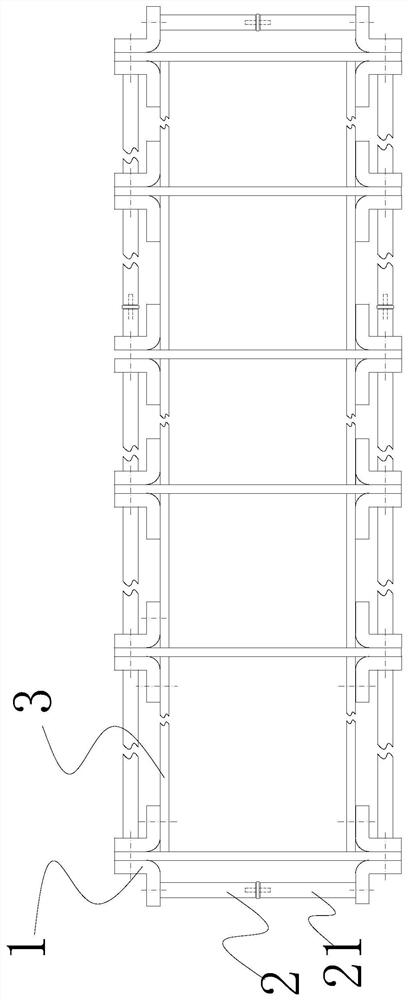

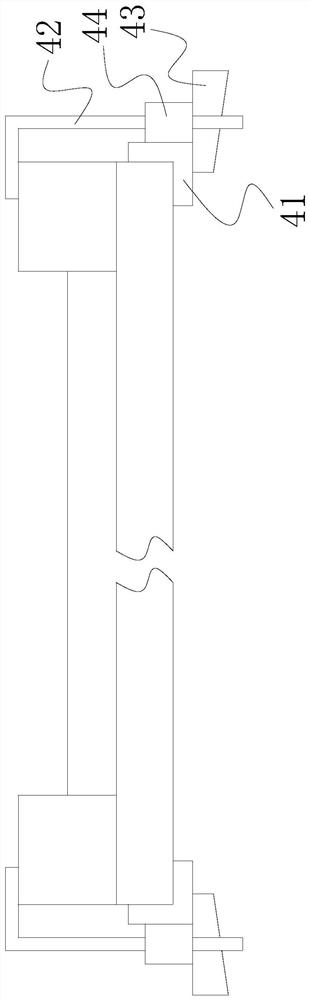

[0033] see Figure 1 to Figure 5 . It is a construction method of a combined formwork, and the combined formwork used includes a column 1, a connecting beam 2, and a panel 3. The number of columns 1 is twelve, and each column is composed of a first angle aluminum and a second angle aluminum. The two folded edges of each corner aluminum are respectively provided with a plurality of connection holes distributed along the length direction at intervals. The panel is a hollow plastic plate, and the number of the connecting beams 2 is multiple, and each connecting beam 2 is a bar-shaped structure made of aluminum, and the two-axis end surfaces of the bar-shaped structure are respectively provided with threaded holes. The specific steps are:

[0034] 1) According to the construction drawings, the position line of the wall body, the position line of the door opening, and the position line of the window opening pop up on the floor. They are all elongated, and the width is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com