Anchor rod drilling machine with geological recognition function

A rock bolt rig, functional technology, applied in bolt installation, directional drilling, earthwork drilling and mining, etc., can solve problems such as unfavorable drilling work, safety accidents, difficult geological real-time grasp, etc., to improve convenience, practicability, and guarantee The effect of safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

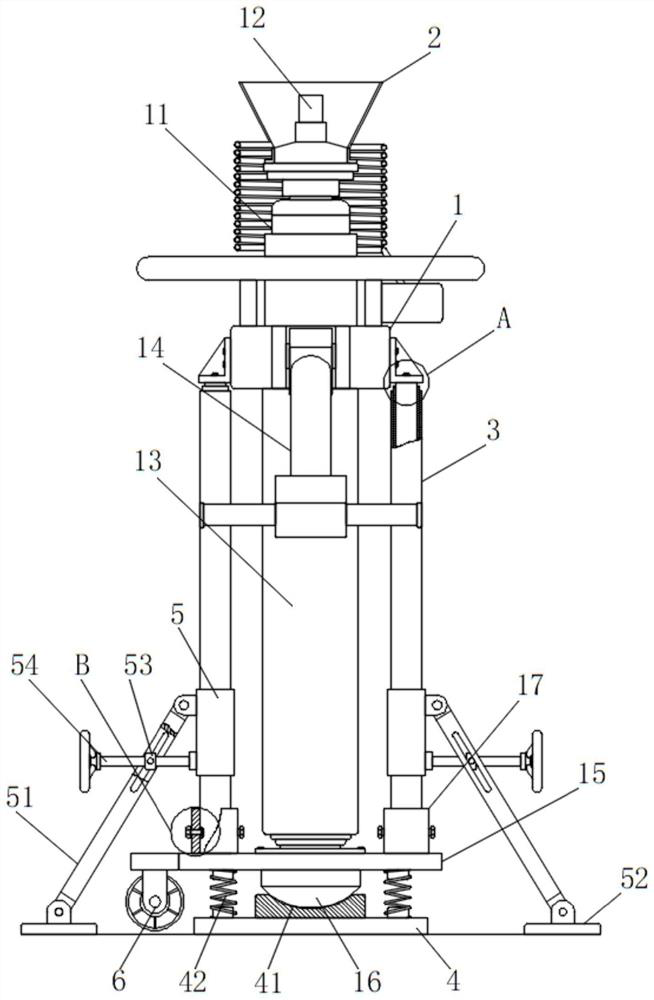

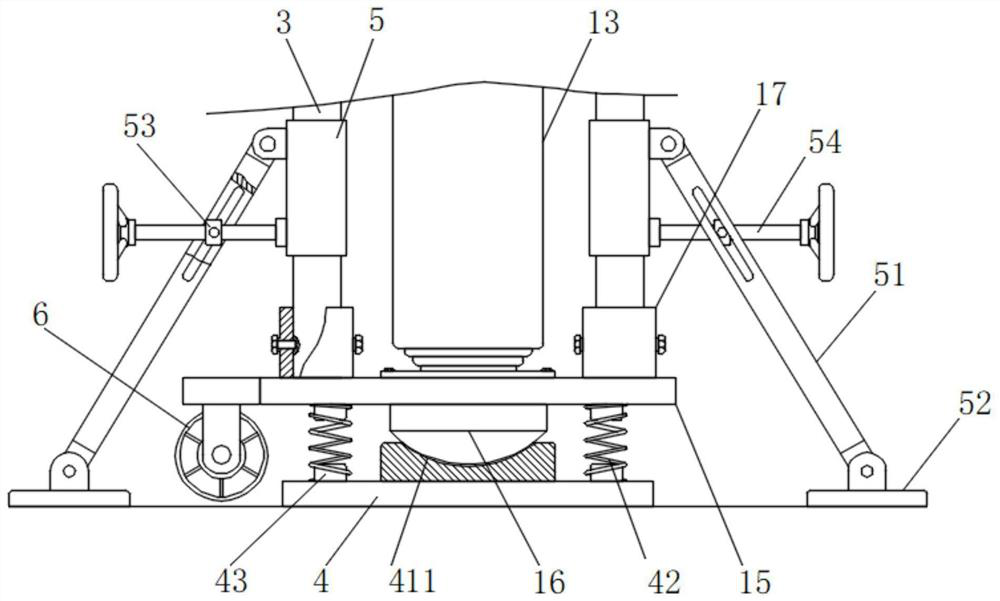

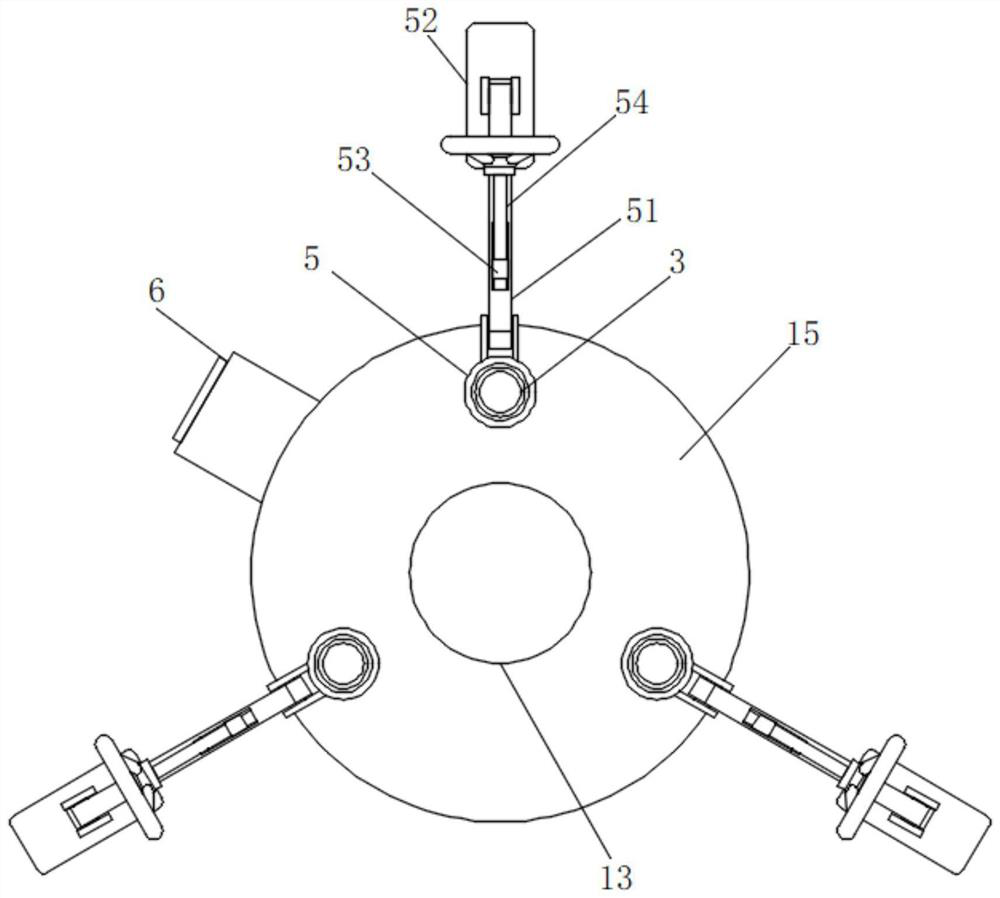

[0035] The implementation method is as follows: insert the hexagonal drill pipe into the hexagonal hole of the drill pipe joint 12, let the drill pipe slowly rotate, use the expansion and contraction of the outrigger 13 to drive the drill pipe to rise slowly, and then the drilling work can be carried out, and by driving Three sets of telescopic guide rod assemblies 3 are arranged outside the assembly 11, and the bottom end of the outer sleeve rod 31 is fixedly connected with the bottom connecting plate 15 through the installation sleeve 17, so that when the bottom end of the supporting leg 13 drives the assembly 11 to go up and down, Utilizing the sliding cooperation of the sliding rod 33, the lining rod 32 and the outer rod 31, the lifting and lowering of the drive assembly 11 can be guided and supported, so that the equipment can work more smoothly when lifting, thereby ensuring the stable operation of the equipment without accidental tilting. safety accidents, and by install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com