Heat dissipation aluminum pipe for robot arm

A technology of robot arms and aluminum tubes, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of wasting manpower and material resources, inconvenient disassembly and replacement, and manual cleaning troubles, and achieve the goal of accelerating heat The effect of dissipating, increasing the contact surface, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 includes a cooling mechanism 1 , and a protection mechanism 2 is arranged inside the cooling mechanism 1 .

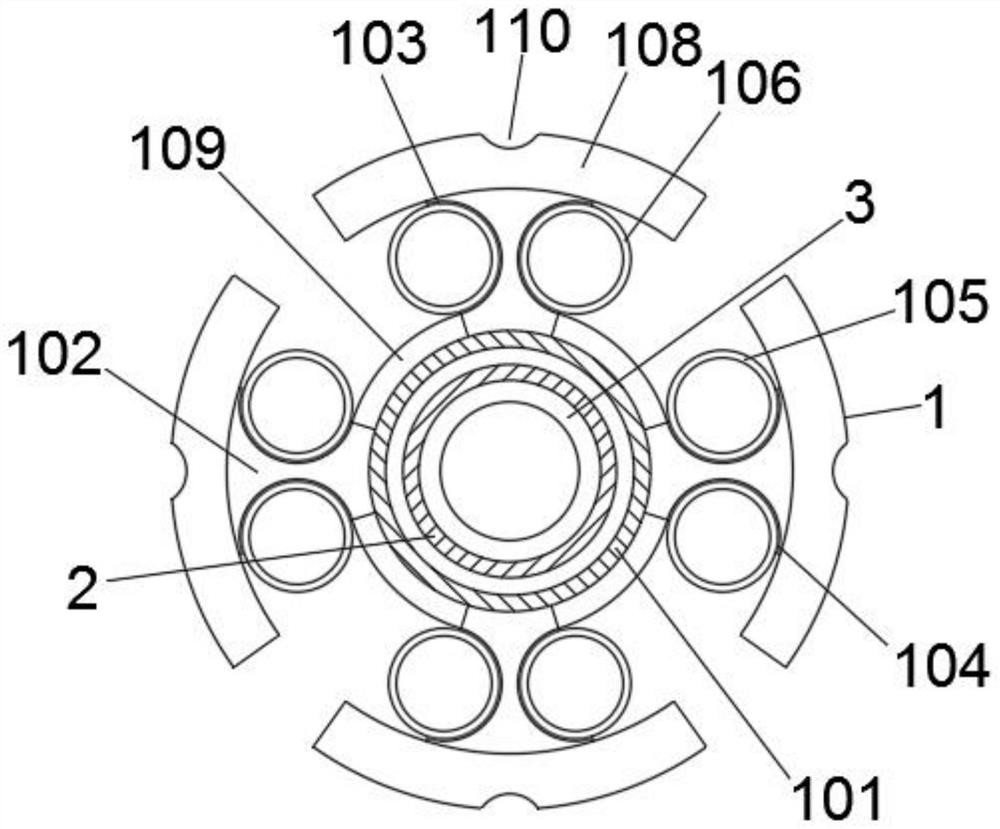

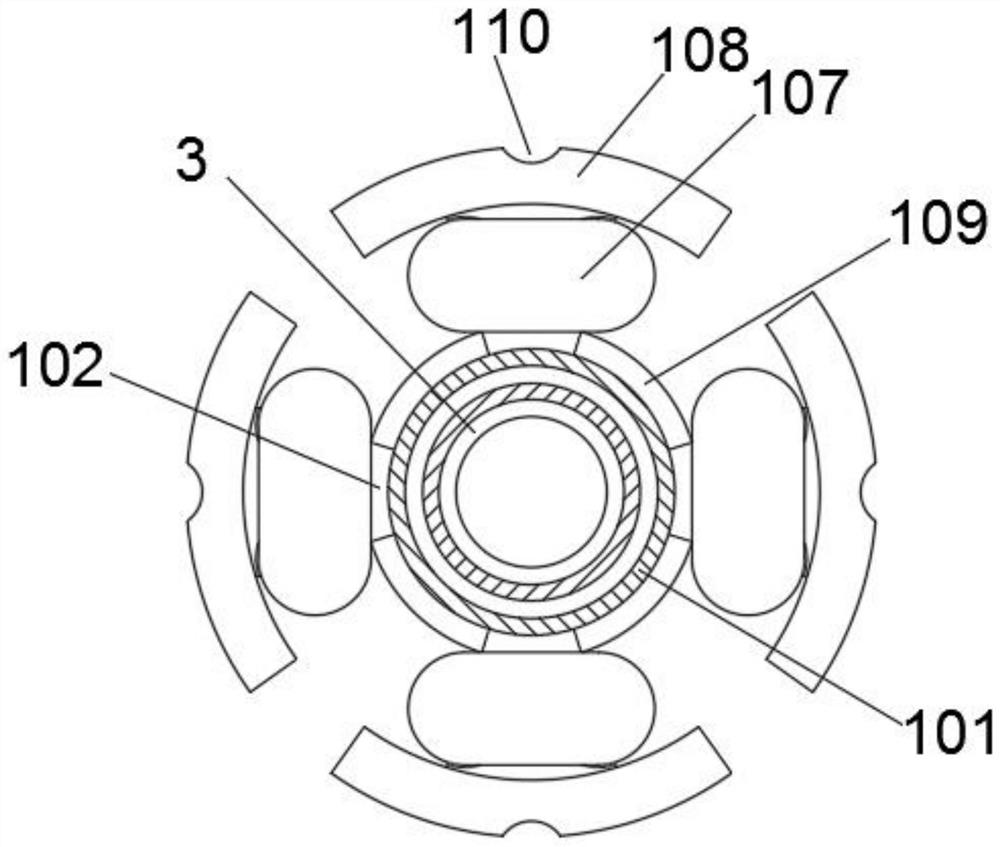

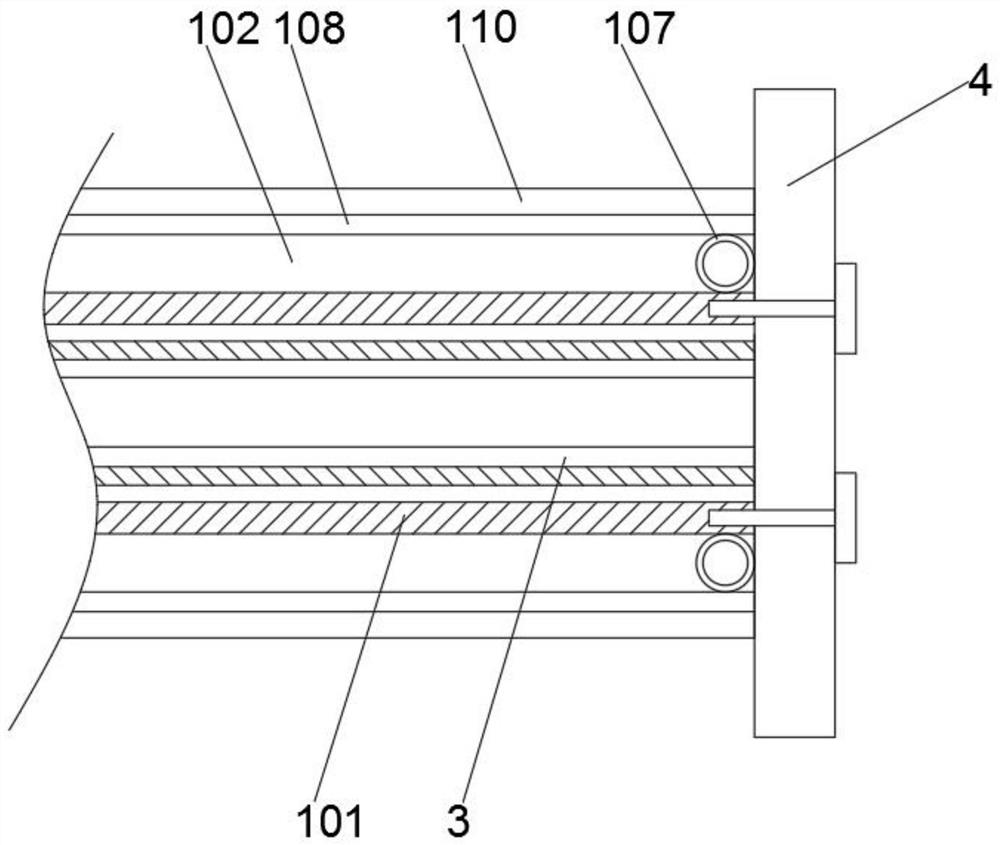

[0024] like figure 1 , figure 2 and image 3 As shown, the cooling mechanism 1 includes a support sleeve 101, four support frames 102 are fixedly connected to the outer surface of the support sleeve 101, and one side of the outer surface of the four support frames 102 is provided with a first arc groove 103, and the four The other side of the outer surface of the support frame 102 is provided with a second arc groove 104, the inner surfaces of the four first arc grooves 103 are fixedly connected with the water inlet pipe 105, and the inner surfaces of the four second arc grooves 104 are all fixed. A water outlet pipe 106 is connected, and the inner surfaces of the four support frames 102 are fixedly embedded with a connector 107, and one end of the four connectors 107 is connected with a water inlet pipe 105, and the other ends of the four connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com