Assembly torque monitoring system and method based on regression neural network

A regression neural network and monitoring system technology, applied in the field of intelligent manufacturing and assembly process monitoring, can solve the problems of reduced monitoring accuracy, performance degradation, and difficult replacement of sensors, so as to reduce assembly space constraints, reduce computation and parameters, and improve The effect of prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

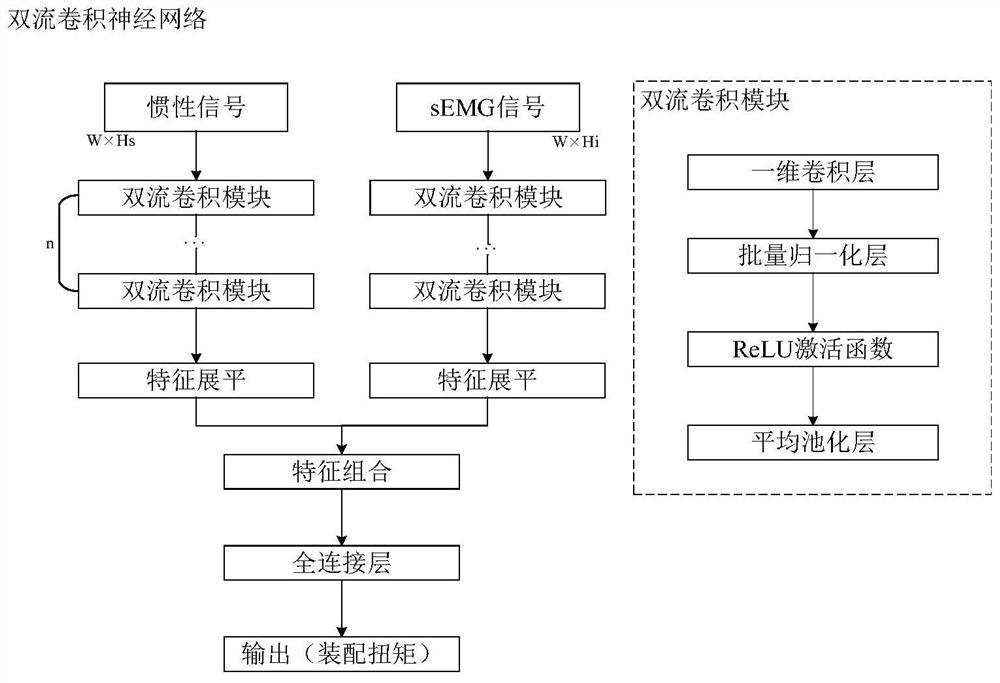

[0034] see figure 1 , an assembly torque monitoring system based on a regression neural network, including a wearable measuring device 1, a torque regression module 2 and a computer 4;

[0035] The wearable measurement device 1 is worn on the operator's arm, and includes a wireless communication unit 13 and a muscle measurement unit 11 and an inertial measurement unit 12 electrically connected to the wireless communication unit; the muscle measurement unit 11 and the inertial measurement unit 12 respectively collect The sEMG signal (surface electromyography signal) and inertial signal generated by the operator during the assembly process, the wireless communication unit 13 is connected to the computer for wireless communication, and is used to send the collected sEMG signal and inertial signal to the computer 4;

[0036] It also includes a torque sample collection device 3, which is arranged on the assembly sample and is electrically connected to the computer 4. The torque sam...

Embodiment 2

[0051] see Figure 4 , an assembly torque monitoring method based on a regression neural network, implemented based on the assembly torque monitoring system based on a regression neural network described in Embodiment 1, comprising the following steps:

[0052] Sample collection phase:

[0053] Step S1, the operator wears the wearable measuring device 1 to perform the assembly operation;

[0054] Step S2, the wearable measuring device 1 collects the sEMG signal and inertial signal of the operator, and the torque sample collection device 3 collects the torque information on the assembly, and transmits it to the computer 4 through the wireless communication unit 13;

[0055] Step S3, the sEMG signal, inertial signal and torque information pass through the data preprocessing module to eliminate signal power frequency interference and signal noise, and establish a sample data set, wherein the preprocessed sEMG signal and inertial signal are used as input, and the preprocessed To...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com