Local sensitivity discriminant analysis method for defect thermal image of composite material

A locally sensitive, discriminant analysis technology, applied in image analysis, image data processing, computer components and other directions, can solve the problems of spatial information without noise, unable to deal with the non-uniform background of thermal images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

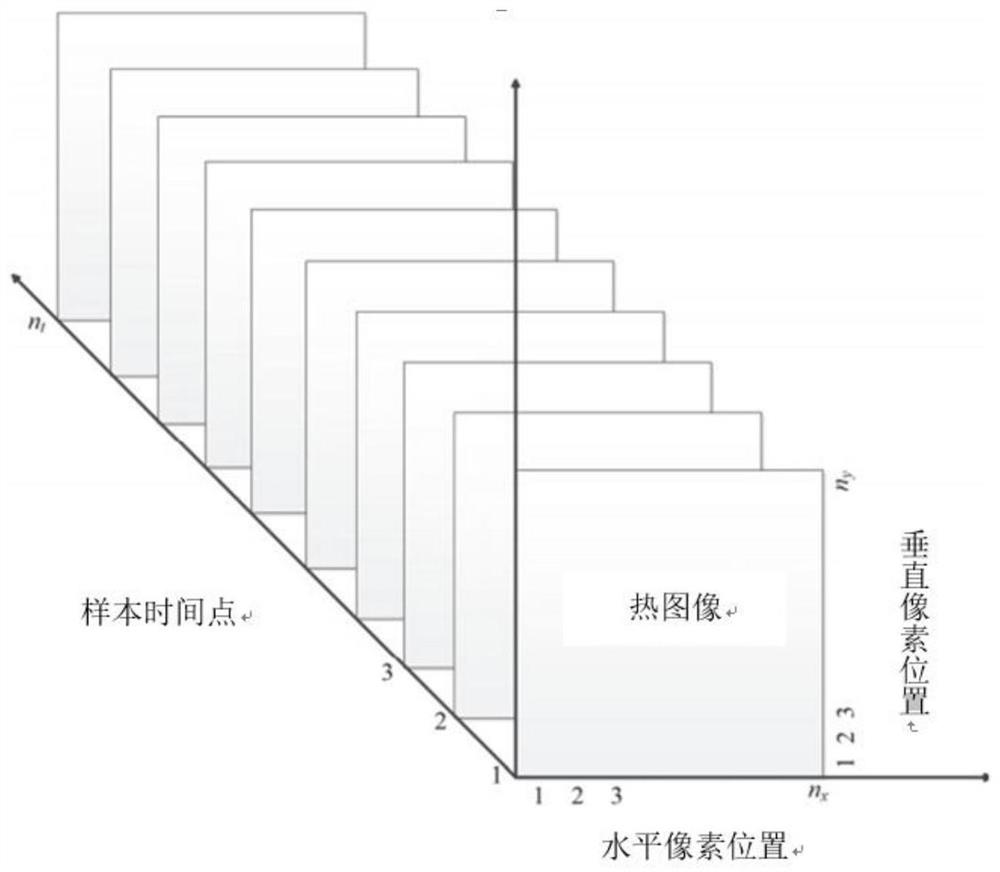

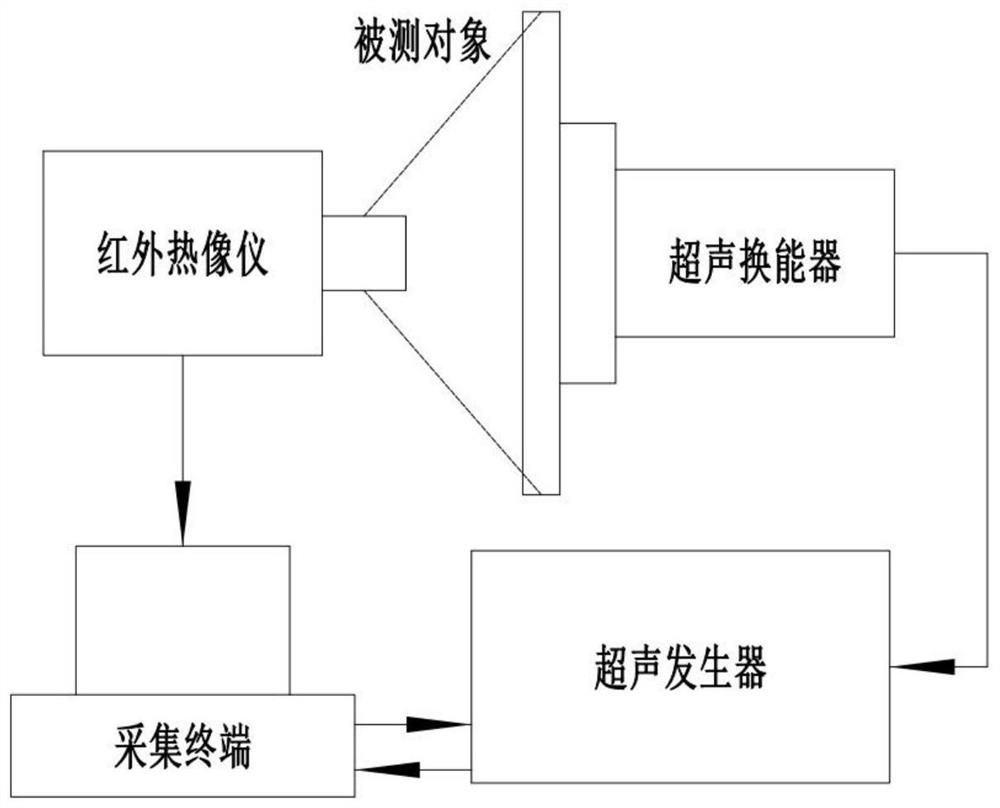

[0075] 1) Acquire defect thermal imaging sequence set:

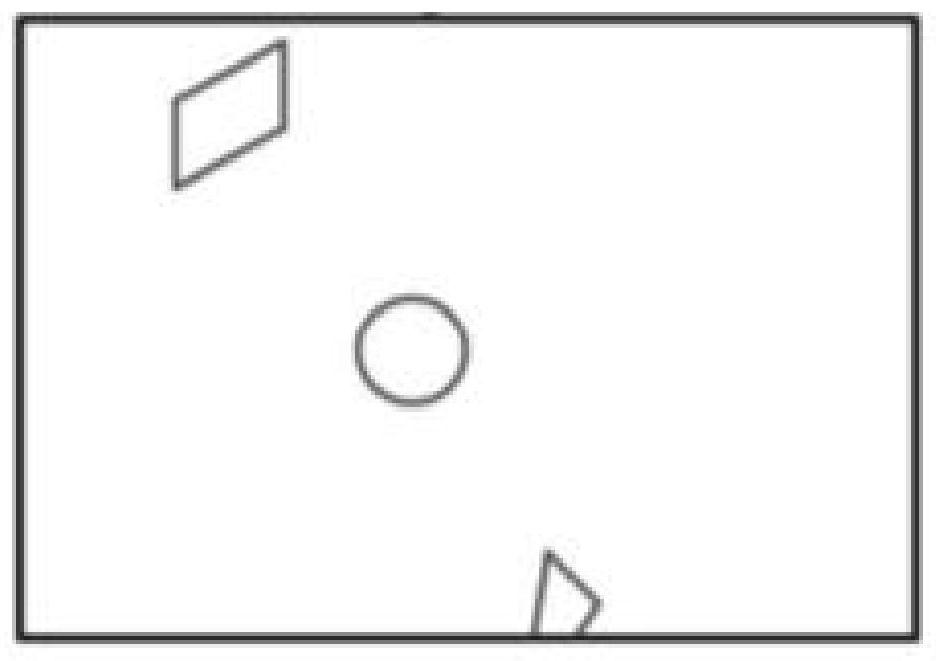

[0076] Three defects with different positions, depths and shapes were implanted in CFRP specimens. The trapezoidal defect is located in the lower right area. Of all three flaws, this one is the shallowest and is under a layer of carbon fiber sheeting. In the middle part of the specimen, there is a circular defect covered by two layers of fibreboard. The deepest defect is located in the upper left corner, it has a diamond shape and is covered by three layers of fiberboard. The area of each defect area is approximately 3 square centimeters.

[0077] For non-destructive testing of defects, we use 3000W ultrasonic pulses as energy and heat pulses to heat the test object. The duration of the heat pulse is approximately 3 milliseconds. Images related to surface temperature were captured in reflectance mode by an infrared camera (TAS-G100EXD, NEC). The resolution of the camera is 320×240 pixels, and the sampling rate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com