Ship cable cutting vehicle

A technology for cables and ships, which is applied in the field of ship cable cutting vehicles, can solve problems such as difficult measurement during cutting, low cable cutting efficiency, and influence on construction progress, and achieve the effects of automatic operation, reduced labor intensity, and improved measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

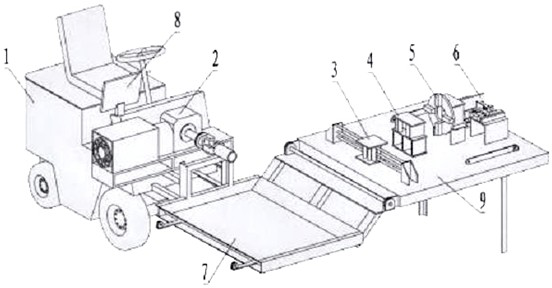

[0035] according to figure 1 As shown, a ship cable cutting vehicle includes: a four-wheel vehicle body 1, a cable winding device 2, an outer diameter measuring device 5, a length measuring device 18, a cable cutting device 6, a buckle mounting seat 19, a host computer 8, a limit Structures such as device 4. The cable barrel placement frame 7 among the figure is used to place the cable barrel. The platform 9 is installed in the figure, and the cutting vehicle can be folded when it moves to transfer the site, which is convenient for the operation of the cutting vehicle and saves space when not in use. After the device installation platform 9 is placed and installed securely, pass the cable from the cable length measuring device 18 through each device on the installation platform 9 in turn and fix it on the cable drum placement frame 7, and install the cable winding device 2 end sleeve 24 on the cable On the cable reel of the drum, cut according to the pre-set cable length and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com