Motor train unit traction motor

A technology for traction motors and EMUs, applied to electric components, electromechanical devices, electrical components, etc., can solve the problems that the ventilation structure is not suitable for intercity EMUs, increase ventilation and heat dissipation efficiency, prolong the life of the motor insulation system, and reduce maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

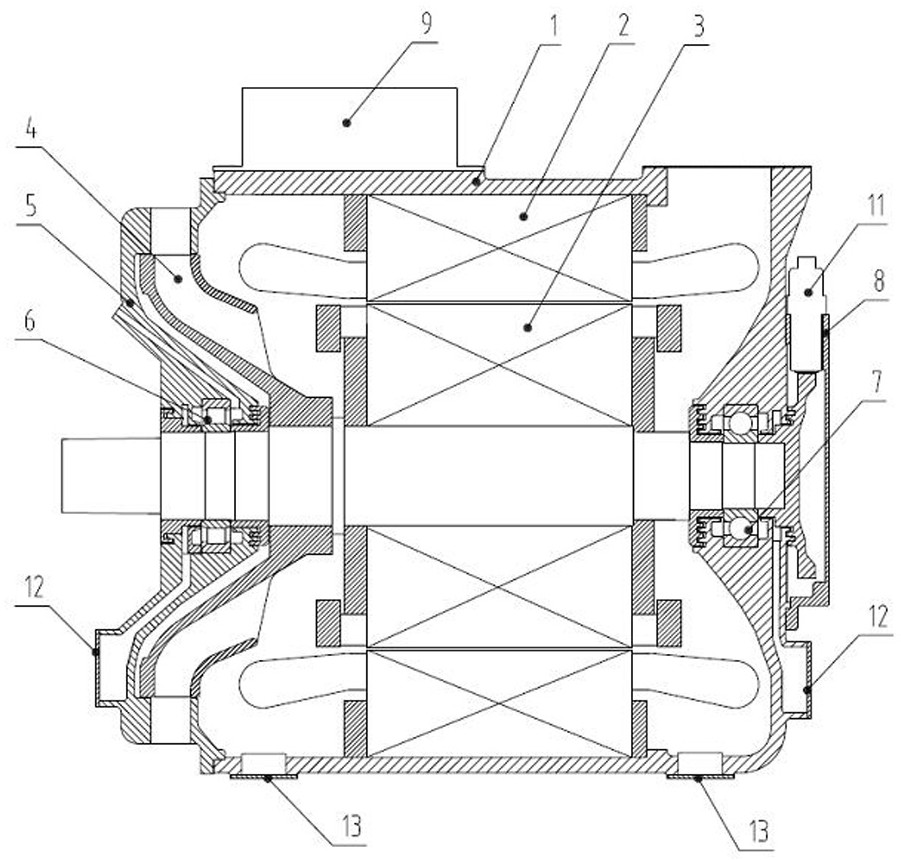

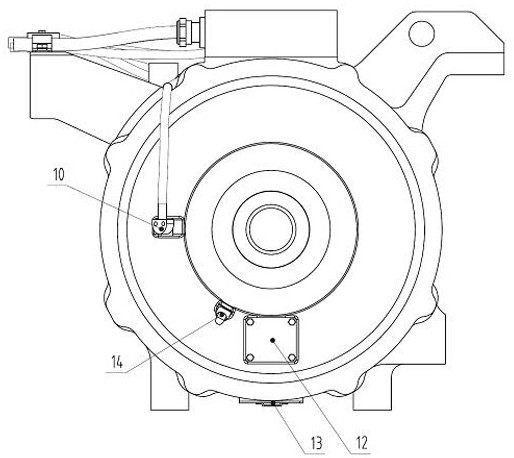

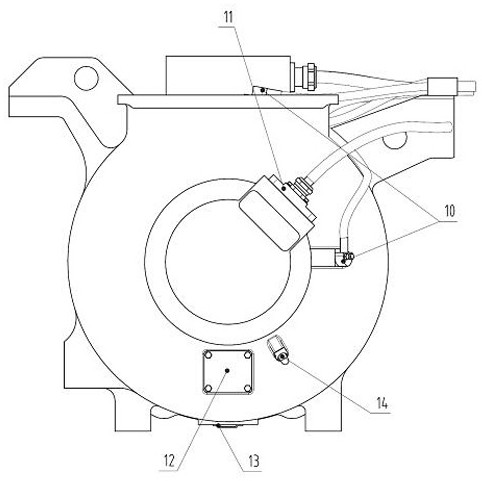

[0029] A traction motor for an EMU, comprising a barrel-shaped machine base 1 (that is, the transmission end of the machine base is open and the non-drive end is not open), the stator core 2 is shrink-fitted in the machine base 1, and the rotor 3 is installed on the rotor 3. The fan 4 at the transmission end of the shaft, and the end cover 5 at the transmission end; the air inlet is opened on the top of the non-transmission end of the frame 1, the air outlet is opened on the side of the end cover 5 of the transmission end, and the rotor 3 is punched with uniform holes in the circumferential direction of the core yoke. Ventilation holes in the cloth; the stator core 2 is punched with evenly distributed ventilation holes in the circumferential direction of the yoke. Such as Figure 4 As shown, the stator core 2 is shrunk into the base 1, and the top of the non-drive end of the base 1 is provided with an air inlet. The internal air path consists of three parts: stator core air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com