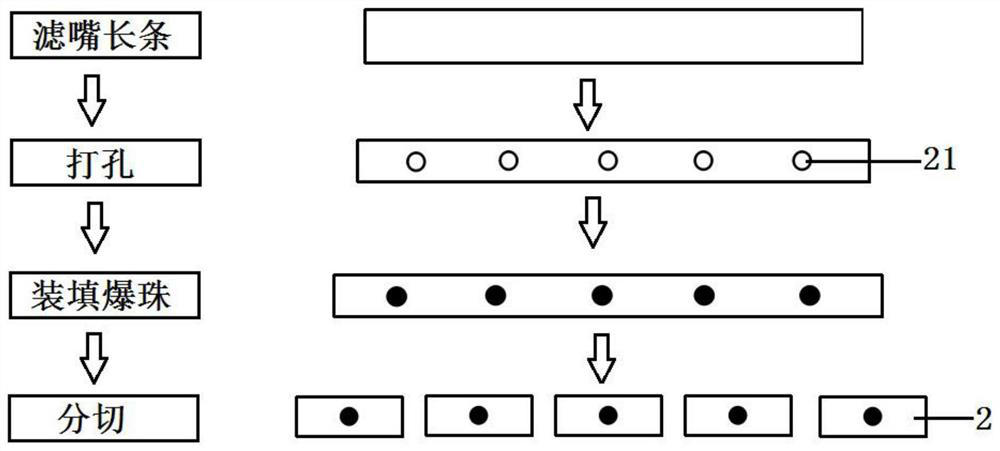

Aerosol generating product containing blasting beads and preparation method of aerosol generating product

An aerosol generation and bead blasting technology, which is applied in the manufacture of cigars, tobacco, food science, etc., can solve problems such as complex molding process, offset, and unqualified products, so as to improve the product qualification rate, simplify the molding process, and expand The effect of selecting a range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

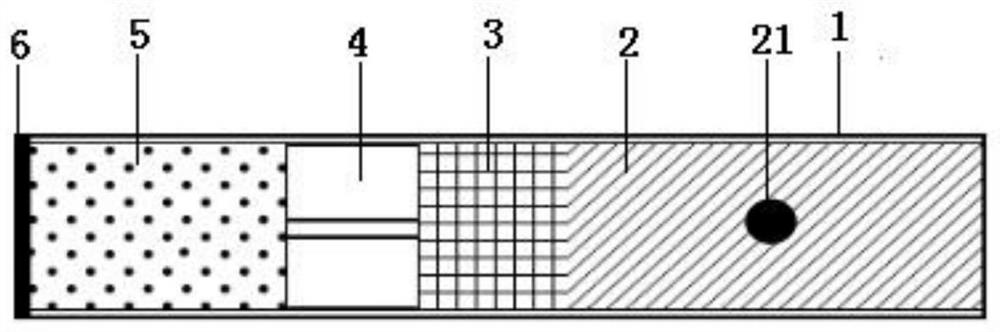

[0039] Such as figure 2 As shown, the aerosol generating product containing explosive beads includes a pipe fitting 1, and a filter section 2, a functional section 3, a cooling section 4, The aerosol generating section 5; the filter section 2 has a radially extending accommodation hole 21; the accommodation hole 21 contains explosive beads.

[0040] The receiving hole 21 penetrates the filter segment 2 in the radial direction. There is one accommodating hole 21 , and each accommodating hole 21 accommodates one. When there is one accommodation hole 21 , the accommodation hole 21 is located in the middle of the axial distance of the filter segment 2 . The diameter of the accommodation hole 21 is 3.5 mm.

[0041] The aerosol generating section 5 is a smoking material in the form of particles, and the end surface of the distal lip end of the pipe member 1 is also provided with a sealing member 6 .

[0042] The functional section 3 is a cavity.

[0043] The cooling section 4 ...

Embodiment 2

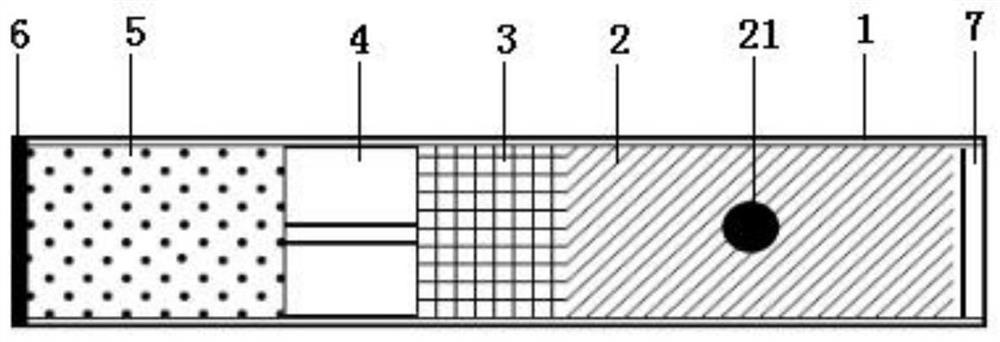

[0050] Such as image 3 , the aerosol generating product containing popping beads in Example 2 is similar to Example 1, the difference is that in the aerosol generating product containing popping beads in Example 2, the filter strip material is polyester fiber, and the There is also an end cavity 7 between the filter segment 2 and the end surface near the lip end of the tube 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com