Bamboo dining table and processing technology thereof

A processing technology and a dining table technology, which is applied in the direction of manufacturing tools, wood processing utensils, tables, etc., can solve the problems of moisture, the surface of the bamboo dining table is easy to be wet or moldy, and the dining table cannot be fully irradiated by sunlight, so as to improve the use effect , The effect of reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

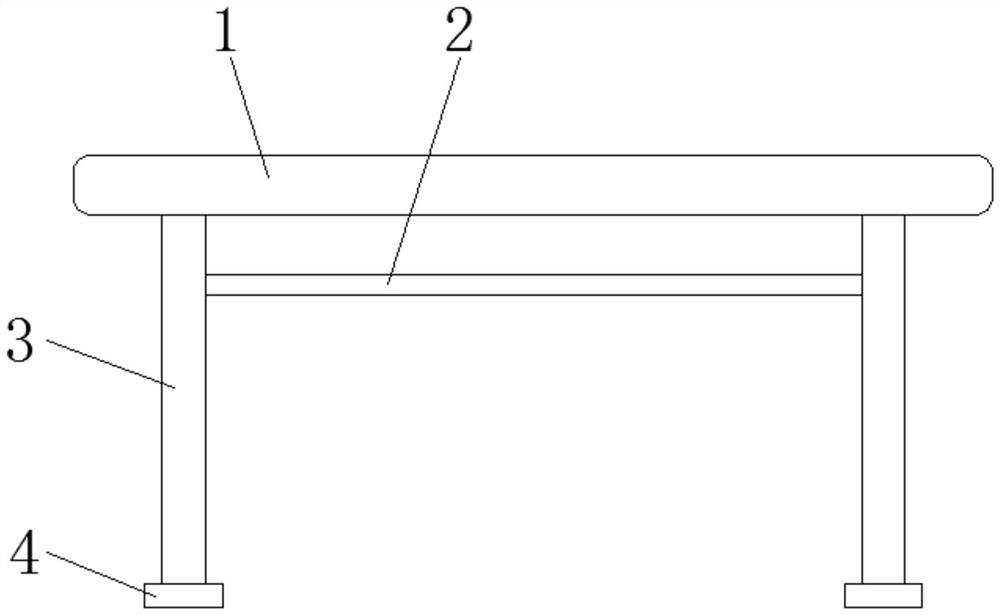

[0025] Such as figure 1 As shown, the present invention provides a technical solution: a bamboo table, including a first table, a second table 2, a vertical rod 3 and a foot pad 4, the lower surface of the first table 1 is close to four corners A second table 2 is fixedly connected between the plurality of vertical rods 3, and the bottom portion of each of the vertical rods 3 is fixedly connected.

[0026] The present invention also provides a processing process for bamboo table, including the following steps:

[0027] S1, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap