Activated carbon-based catalytic flue gas deep desulfurization device

A deep desulfurization and activated carbon technology, applied in the field of flue gas purification, can solve problems such as fragmentation, loss, and low strength of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

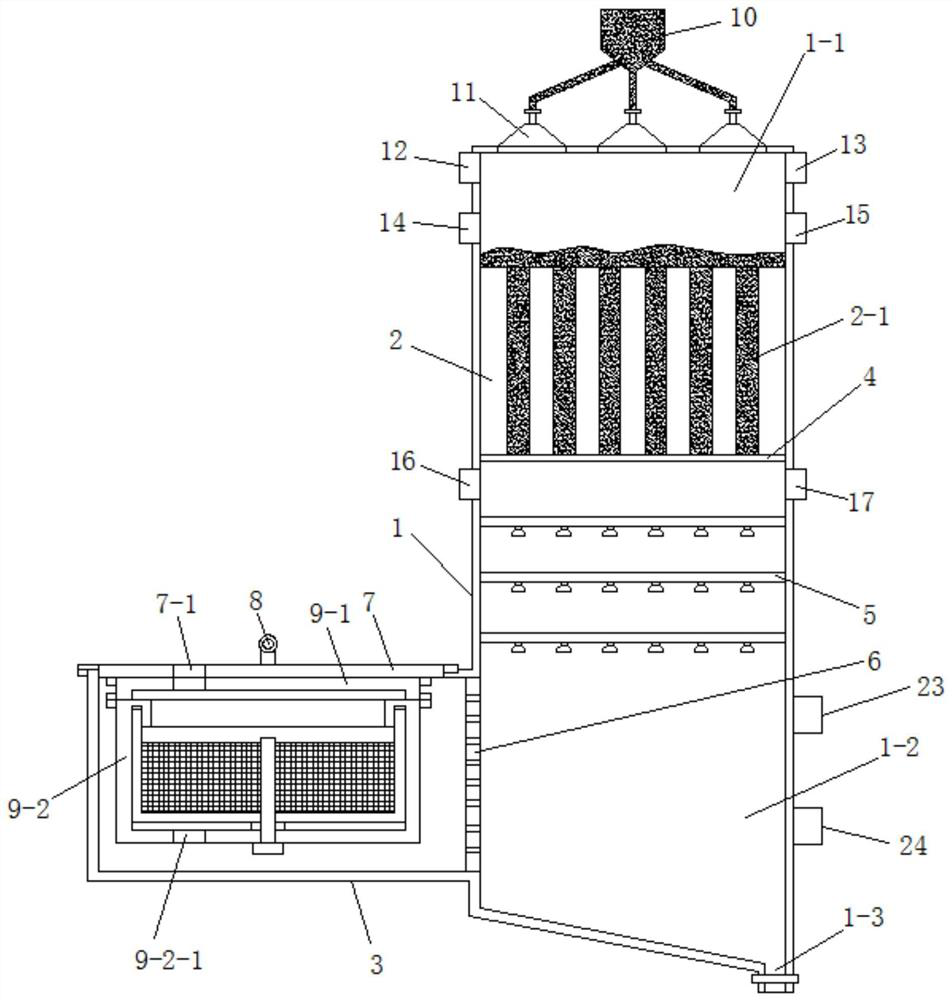

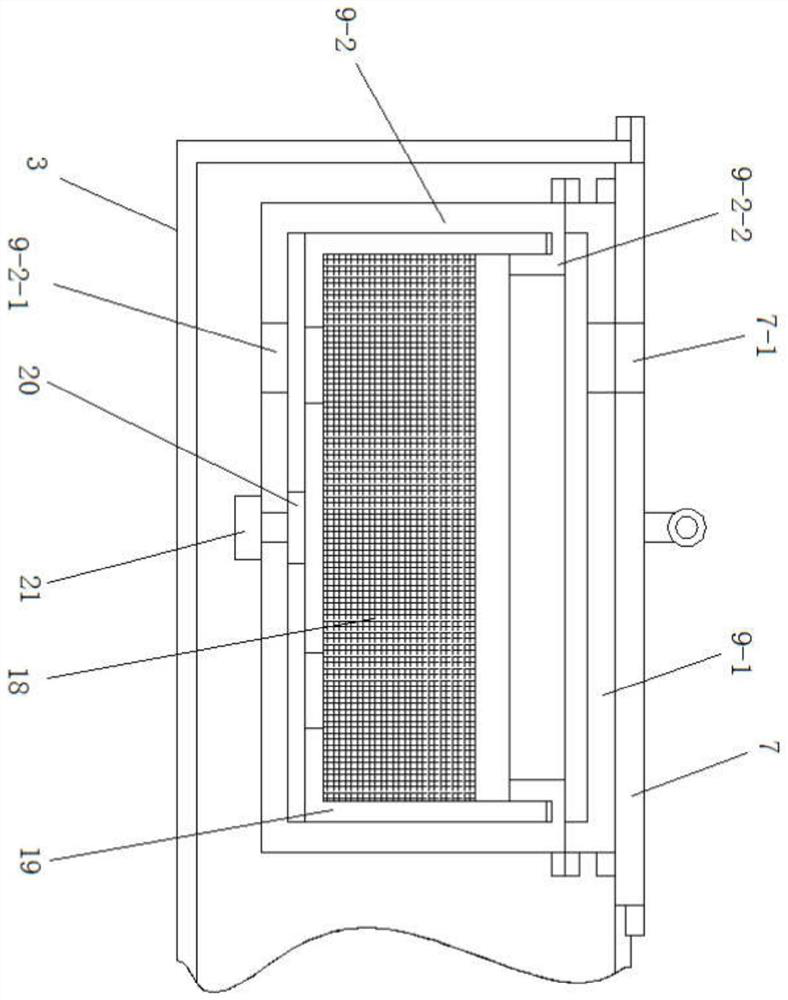

[0014] Such as figure 1 The shown activated carbon-based catalytic flue gas deep desulfurization device includes a desulfurization tower 1 and a desulfurization box 3. The desulfurization box is connected to one side of the lower end of the desulfurization tower and communicates with it. In the desulfurization box, A rotary desulfurization mechanism is provided, and a desulfurization seat 2 is provided in the desulfurization tower. There are several activated carbon channels 2-1 that penetrate up and down in the desulfurization tower. The desulfurization tower below the desulfurization seat is provided There is a restricted grid plate 4, the activated carbon in the desulfurization seat stays in the activated carbon channel through the restricted grid plate, and a spray pipe 5 is also arranged in the desulfurization tower below the restricted grid plate, and the The desulfurization tower is provided with three spray pipes sequentially from top to bottom, and the top of the desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com