Ore pulp treatment device

A processing device and a technology for ore pulp, which are applied in mixers with rotary stirring devices, transportation and packaging, chemical/physical processes, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

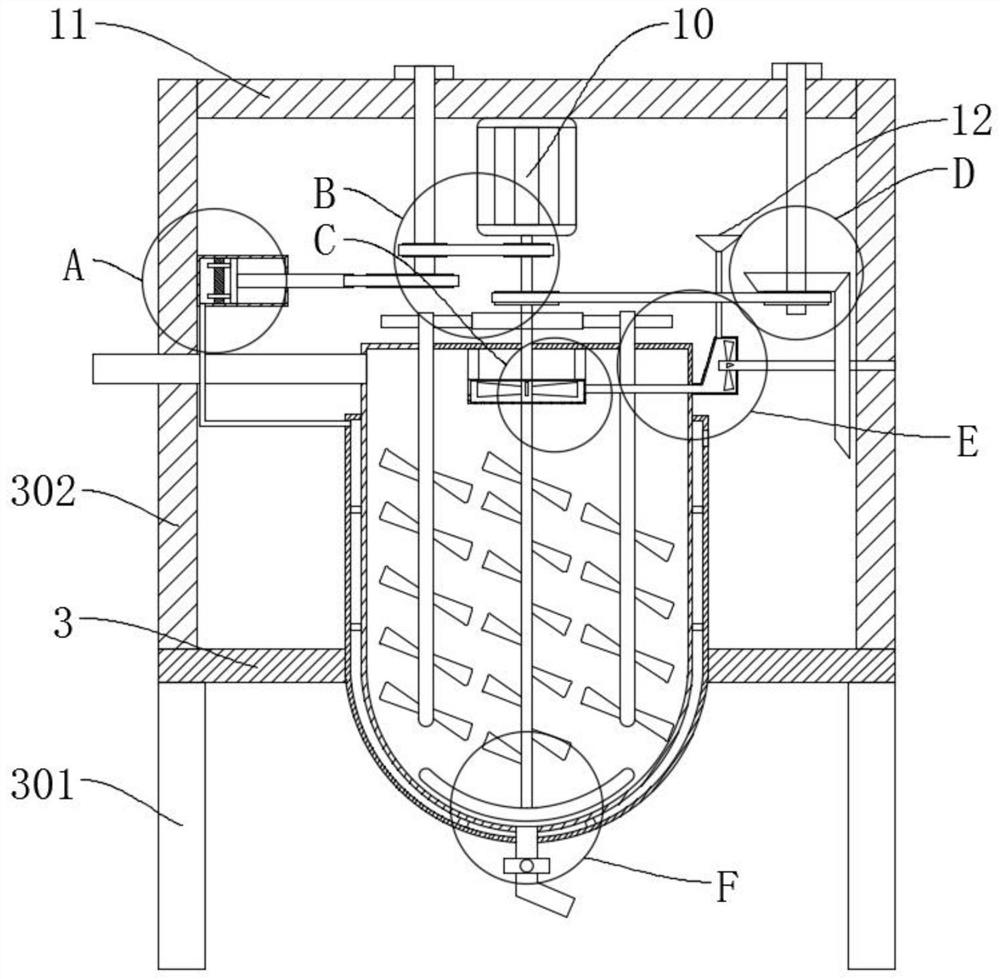

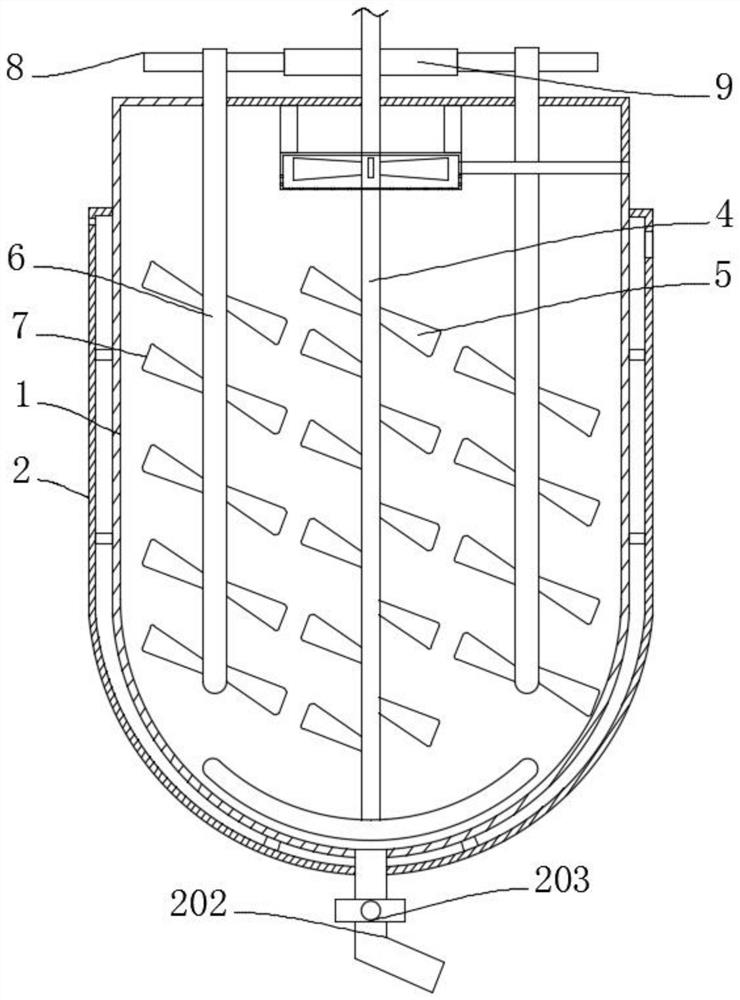

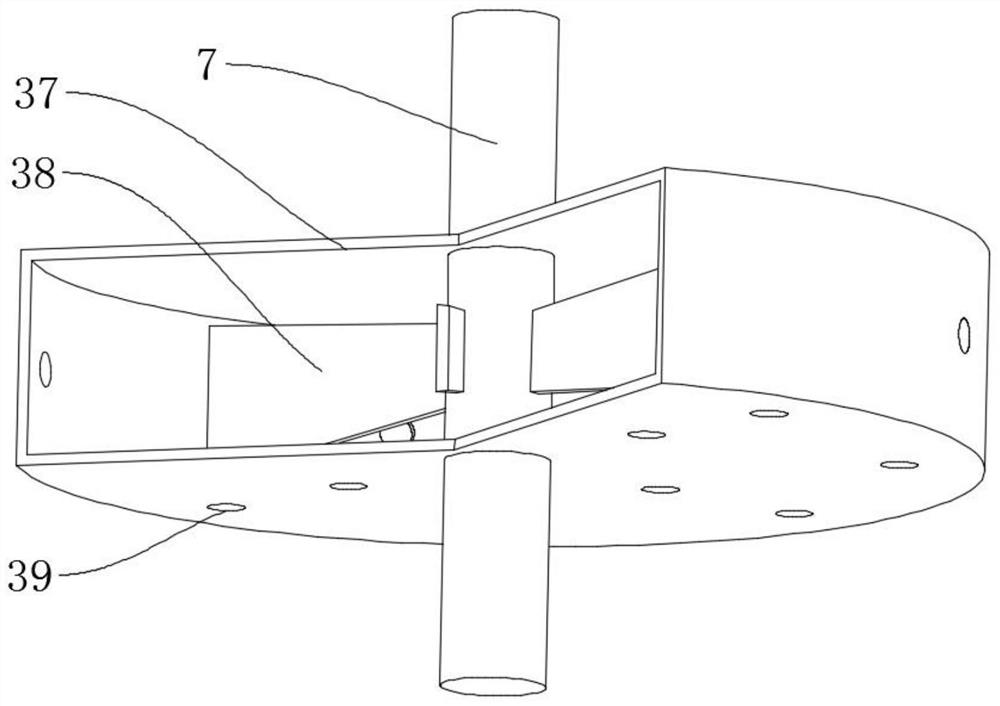

[0034] refer to figure 1 , 2 , 4, 5, a kind of ore pulp treatment device, comprises casing 1, heating mantle 2 and support plate 3, is connected with stirring rod 4 and auxiliary rod 6 in rotation in casing 1, and is respectively fixedly connected on stirring rod 4 and auxiliary rod 6 There are stirring fan blades 5 and auxiliary fan blades 7, the support plate 3 is fixedly connected with a fixed plate 302, the fixed plate 302 is fixedly connected with a top plate 11, the top plate 11 is fixedly connected with a motor 10, and the output end of the motor 10 is fixedly connected with a first The transmission mechanism, the second transmission mechanism and the stirring rod 4, the piston cylinder 14 and the rotating shaft 30 are connected on the fixed plate 302, the piston cylinder 14 is connected with the heating jacket 2 through the air outlet pipe 17, the first transmission mechanism is connected to the piston cylinder 14 in rotation, The rotating shaft 30 is fixedly connecte...

Embodiment 2

[0046] refer to figure 1 , 3 , 6, 7, 8, a pulp processing device, including a box body 1, a heating jacket 2 and a support plate 3, a stirring rod 4 and an auxiliary rod 6 are rotatably connected in the box body 1, and the stirring rod 4 and the auxiliary rod 6 are respectively The stirring blade 5 and the auxiliary blade 7 are fixedly connected, the support plate 3 is fixedly connected with a fixed plate 302, the fixed plate 302 is fixedly connected with a top plate 11, the top plate 11 is fixedly connected with a motor 10, and the output end of the motor 10 is fixedly connected with a The first transmission mechanism, the second transmission mechanism and the stirring rod 4, the fixed plate 302 is connected with the piston cylinder 14 and the rotating shaft 30, the piston cylinder 14 is connected with the heating jacket 2 by the air outlet pipe 17, and the first transmission mechanism and the piston cylinder 14 rotate The feeding fan blade 31 and the second bevel gear 29 ar...

Embodiment 3

[0058] refer to figure 1 , 9 , a pulp processing device, including a box body 1, a heating jacket 2 and a support plate 3, a stirring rod 4 and an auxiliary rod 6 are rotatably connected in the box body 1, and stirring fan blades are respectively fixedly connected to the stirring rod 4 and the auxiliary rod 6 5 and the auxiliary fan blade 7, the support plate 3 is fixedly connected with a fixed plate 302, the fixed plate 302 is fixedly connected with a top plate 11, the top plate 11 is fixedly connected with a motor 10, and the output end of the motor 10 is fixedly connected with a first transmission mechanism, a second The second transmission mechanism and the stirring rod 4, the fixed plate 302 is connected with the piston cylinder 14 and the rotating shaft 30, the piston cylinder 14 is connected with the heating jacket 2 through the air outlet pipe 17, the first transmission mechanism is connected with the piston cylinder 14 in rotation, and the rotating shaft 30 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com