A fully automatic blanking equipment for drying racks

A fully automatic, drying rack technology, applied in shearing machine equipment, metal processing equipment, pipe cutting devices, etc., can solve the problems of time-consuming and labor-intensive, low production efficiency, inability to complete automatic blanking, etc., and achieve the elimination of manual labor. Operation, the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] next combined with Figure 1-8 A specific embodiment of the present invention is described in detail.

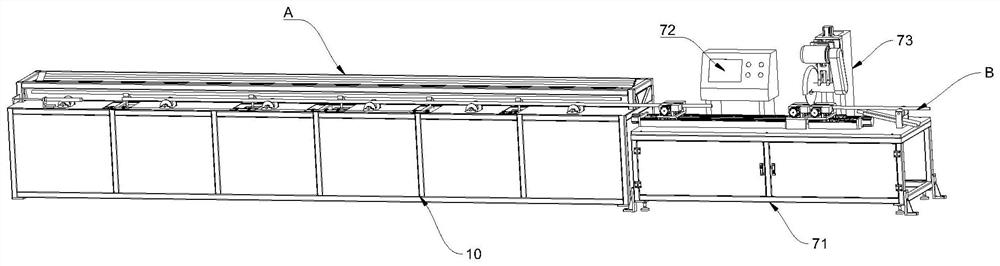

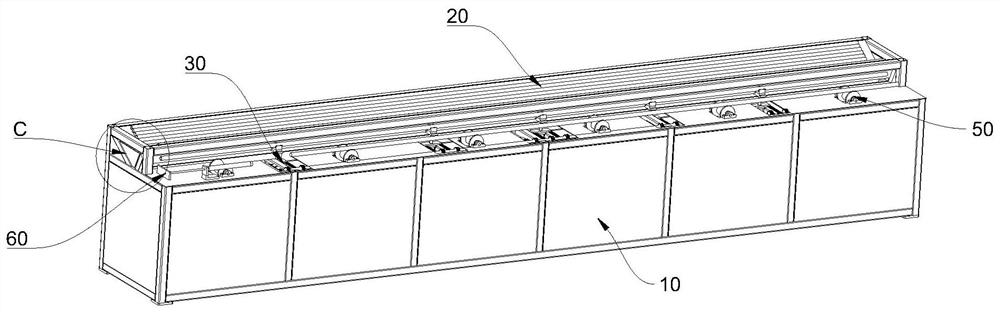

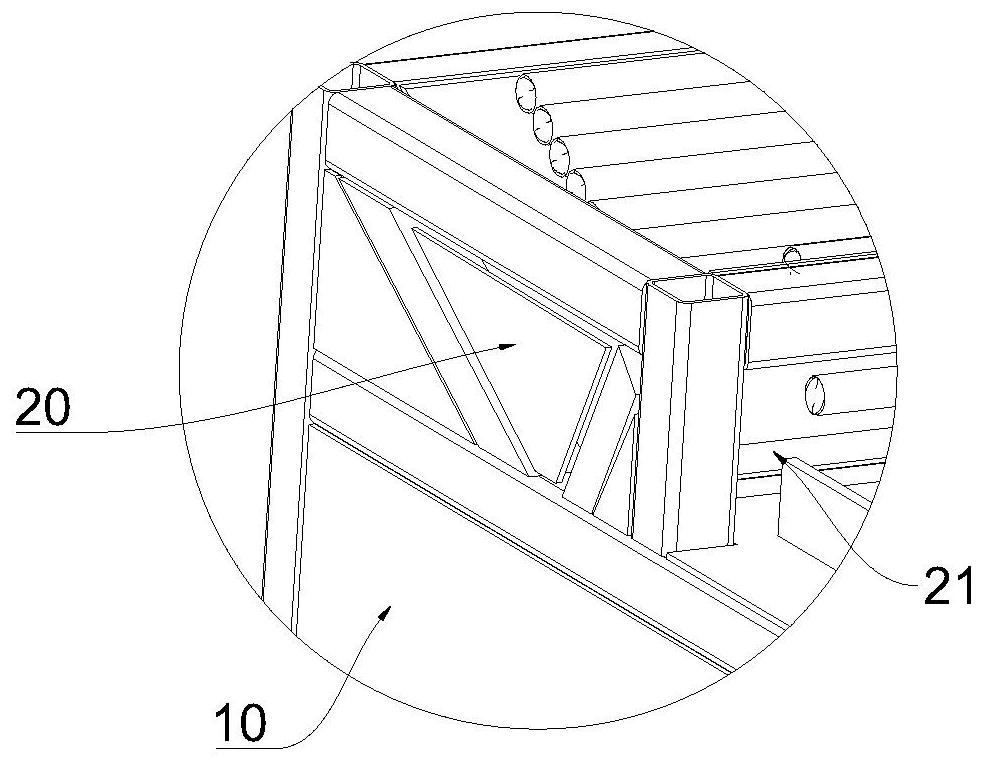

[0026] Reference attached Figure 1-8 , a kind of automatic blanking equipment for drying racks, including a frame 10 standing on the ground, the frame 10 is provided with a blanking bin 20, and the pipe fittings that need to be blanked are placed in the blanking bin 20 to enter the subsequent process, so The cross-section of the lower silo 20 is V-shaped, and one side of the bottom is provided with a discharge chute 21. The width of the discharge chute 21 is greater than the diameter of the pipe fitting and less than twice the diameter of the pipe fitting, preferably only slightly larger than the diameter of the pipe fitting. The lower silo 20 is V-shaped, and the pipes are piled up at the bottom of the lower silo 20 .

[0027] Reference attached Figure 4 , the feeding and transferring mechanism 30 is arranged on the frame 10, and the quantity of the feeding and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com