Feeding mechanism special for ceramic 3D printer

A technology of 3D printer and feeding mechanism, which is applied in the field of ceramic strengthening, and can solve the problems of closed feeding mechanism and inconvenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

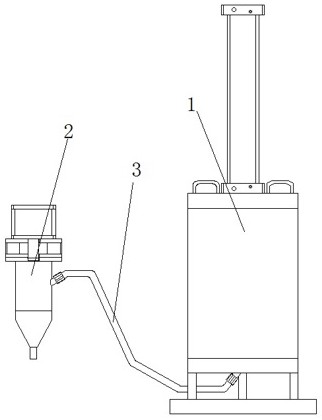

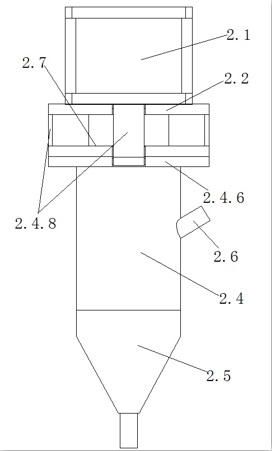

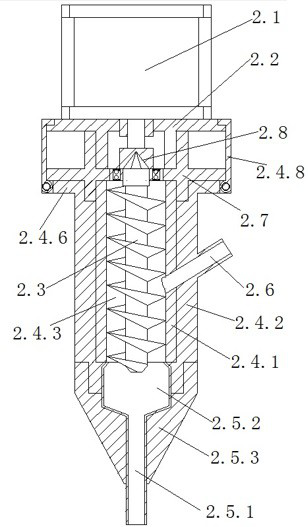

[0054] This embodiment discloses a special feeding mechanism for ceramic 3D printers. As a basic embodiment of the present invention, it includes a feeding barrel 1, a printing head 2 and a feeding hose 3, wherein the printing head 2 includes a feeding motor 2.1 assembly , feeding screw 2.3, working head and connecting seat 2.7; the assembly of feeding motor 2.1 includes feeding motor 2.1, and the working head includes feeding pipe 2.4 and discharging head 2.5; The end of the feeding screw 2.3 near the top is rotationally connected with the connecting seat 2.7 through the installation hole; the connecting seat 2.7 is detachably connected with the feeding motor 2.1 assembly, and is used to connect the feeding screw 2.3 with the rotating shaft of the feeding motor 2.1 assembly coaxially, and Axially fix the rotating shaft of the feeding screw 2.3 and the feeding motor 2.1 assembly; the top of the feeding screw 2.3 and the end of the rotating shaft of the feeding motor 2.1 assembl...

Embodiment 2

[0057] This example discloses a special feeding mechanism for ceramic 3D printers. As a preferred embodiment of the present invention, that is, in Example 1, the feeding barrel 1 includes a cylinder 1.1, a mud pressing plate 1.2, a base 1.5, a barrel body 1.3 and A top cover 1.4 matching the barrel body 1.3; the barrel body 1.3 is a hollow cylinder structure with top and bottom openings, and the top cover 1.4 covers the opening at the top of the barrel body 1.3 and is detachably connected to the top of the barrel body 1.3 The mud pressing plate 1.2 is detachably arranged inside the barrel body 1.3, and the edge of the mud pressing plate 1.2 is in airtight contact with the inner wall of the barrel body 1.3; the cylinder 1.1 is fixedly connected to the top of the top cover 1.4, and the push rod of the cylinder 1.1 runs through The top cover 1.4 is detachably connected to the top of the mud pressing plate 1.2; the base 1.5 includes a sealed bottom cover 1.5.1, a support disc 1.5.2...

Embodiment 3

[0060] This embodiment discloses a special feeding mechanism for ceramic 3D printers. As a preferred embodiment of the present invention, that is, in Embodiment 2, the end of the barrel body 1.3 near the top and the end near the bottom are respectively provided with external thread structures 1.3. 1. The top cover 1.4 and the sealing bottom cover 1.5.1 are respectively provided with an internal thread structure 1.6, and the inside of the sealing bottom cover 1.5.1 is provided with an elastic sealing ring 1.5.5; the external thread structure 1.3.1 and the internal thread structure 1.6 cooperate with each other, so that the top cover 1.4 and the sealed bottom cover 1.5.1 are respectively screw-connected with the barrel body 1.3; the top of the mud pressing plate 1.2 is provided with an installation groove 1.2.1, and the installation groove 1.2.1 is provided with a waterproof bearing part II 2.7.4 , the mud-pressing plate 1.2 is fixedly connected to the outer ring of the waterproo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com