Water treatment purifier

A technology of water treatment and purifier, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of inconvenient use, poor removal of small particles of impurities, and inability to effectively use water. Filtration devices and other issues to achieve the effect of saving consumption and improving high-efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

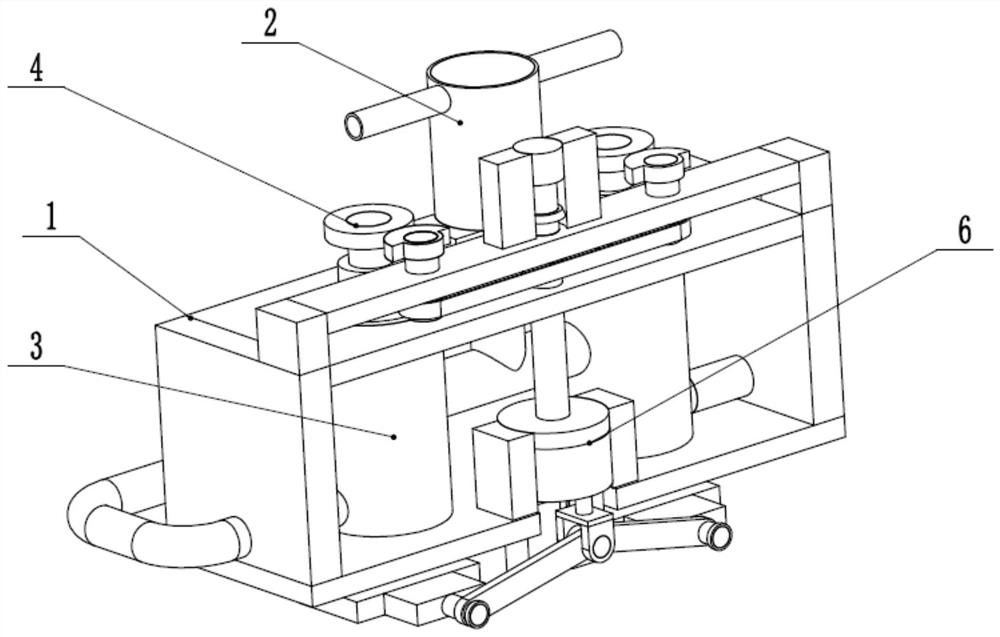

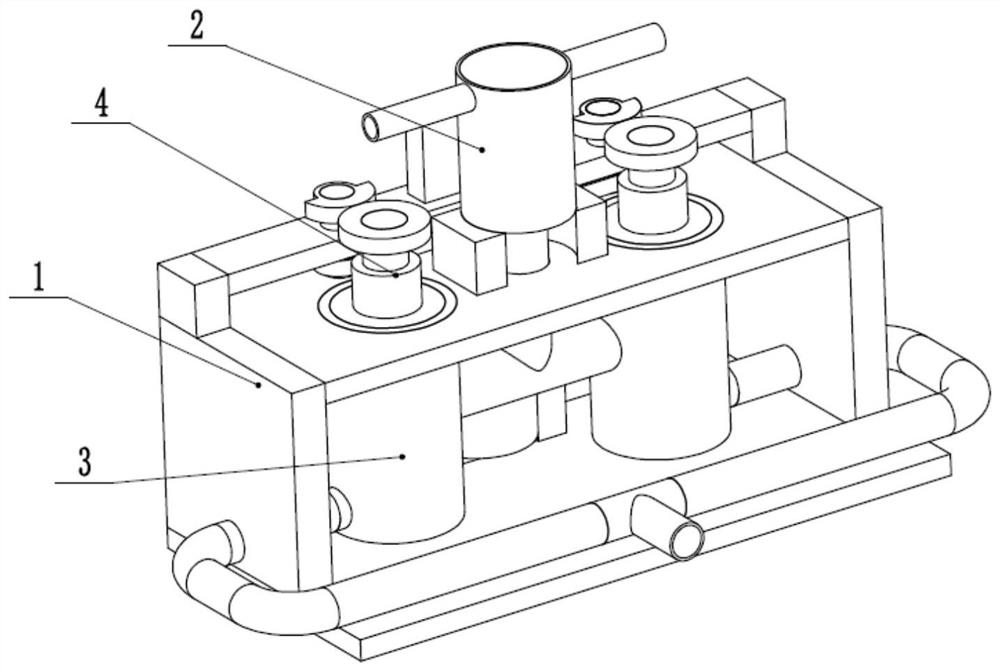

[0031] Such as Figure 1 to Figure 11As shown, a water treatment purifier includes a water treatment bottom frame 1, a flocculant mixing and adding cylinder 2, two filter impurity removal cylinders 3, two rotary adsorbers 4, two filter element scraping platforms 5 and a combined drive 6, The flocculant mixing and adding cylinder 2 is fixedly connected to the upper end of the water treatment chassis 1, and the flocculant mixing and adding cylinder 2 is connected to two filter and impurity removal cylinders 3 through pipelines, and the two filter and impurity removal cylinders 3 are connected by pipelines. Two filter and impurity removal cylinders 3 are uniformly and fixedly connected in the water treatment chassis 1, two rotary adsorbers 4 are respectively rotatably connected in the two filter and impurity removal cylinders 3, and two filter element scrapers 5 are respectively sealed and slidably connected to the two In the filter and impurity removal cylinder 3, the combinatio...

specific Embodiment approach 2

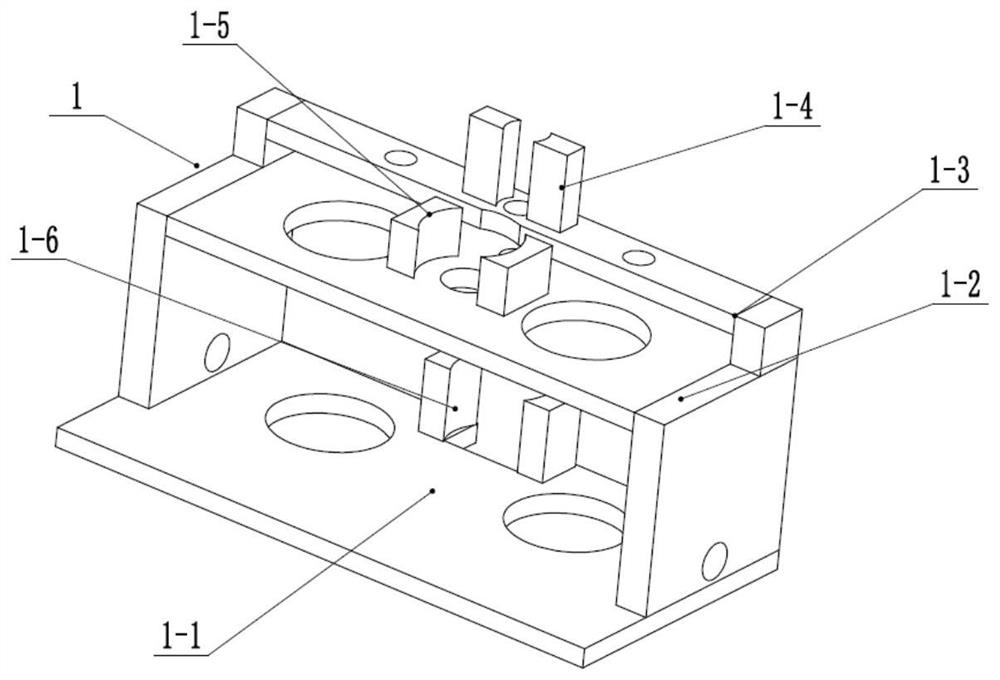

[0033] Such as Figure 1 to Figure 11 As shown, this embodiment will further explain Embodiment 1. The water treatment chassis 1 includes a fixed bottom plate 1-1, a middle fixed concave platform 1-2, an upper fixed concave platform 1-3, and a motor fixed platform 1. -4. The cylinder supporting platform 1-5 and the limit rotation frame 1-6, the middle fixed concave platform 1-2 is fixedly connected to the upper end of the fixed bottom plate 1-1, and the upper fixed concave platform 1-3 is fixedly connected to the middle The upper end of the fixed concave platform 1-2, the motor fixed platform 1-4 is fixedly connected on the upper fixed concave platform 1-3, and the cylinder support platform 1-5 is fixedly connected on the middle fixed concave platform 1-2. The bit rotating frame 1-6 is fixedly connected on the fixed base plate 1-1.

specific Embodiment approach 3

[0035] Such as Figure 1 to Figure 11 As shown, this embodiment will further explain Embodiment 2. The flocculant mixing and adding cylinder 2 includes a mixing cylinder 2-1, two adding pipes 2-2, a driven bevel gear 2-3, and a stirring shaft 2 -4. The inner rotating seat 2-5 and a plurality of stirring fins 2-6, the two ends of the mixing cylinder 2-1 are respectively fixedly connected and communicated with two adding pipes 2-2, and the driven bevel gear 2-3 is fixedly connected On the stirring shaft 2-4, the stirring shaft 2-4 is sealed and rotatably connected to the mixing cylinder 2-1 and the inner rotating seat 2-5, and the inner rotating seat 2-5 is fixedly connected to the inner wall of the mixing cylinder 2-1 , a plurality of stirring fins 2-6 are uniformly and fixedly connected to the stirring shaft 2-4. Sewage and flocculant are respectively added into the mixing cylinder 2-1 through two adding pipes 2-2, driven by the driving bevel gear 6-3 in the mixing cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com