Household garbage incinerator bottom slag dry hard concrete and preparation method thereof

A technology of domestic waste incineration and dry hard concrete is applied in the field of building materials to achieve the effect of solving the problem of occupying land resources, good drying shrinkage performance, and avoiding excessive performance decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

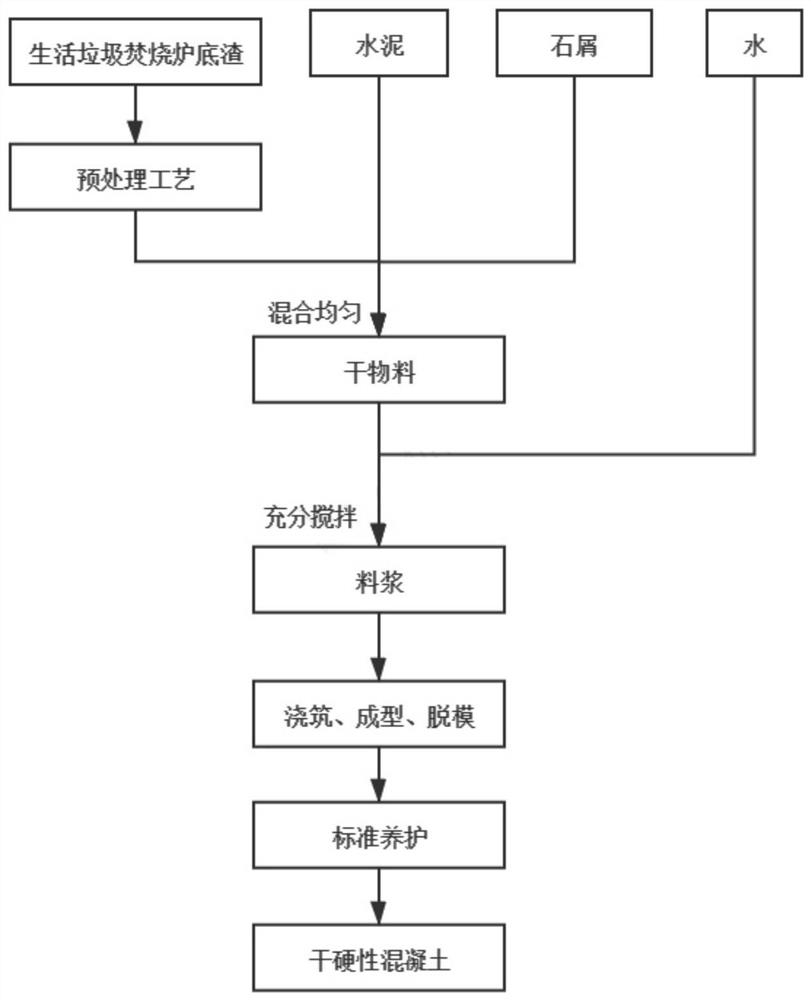

[0036] see Figure 1 to Figure 3 , the present invention also provides the preparation method of above-mentioned dry hard concrete, comprises the following steps:

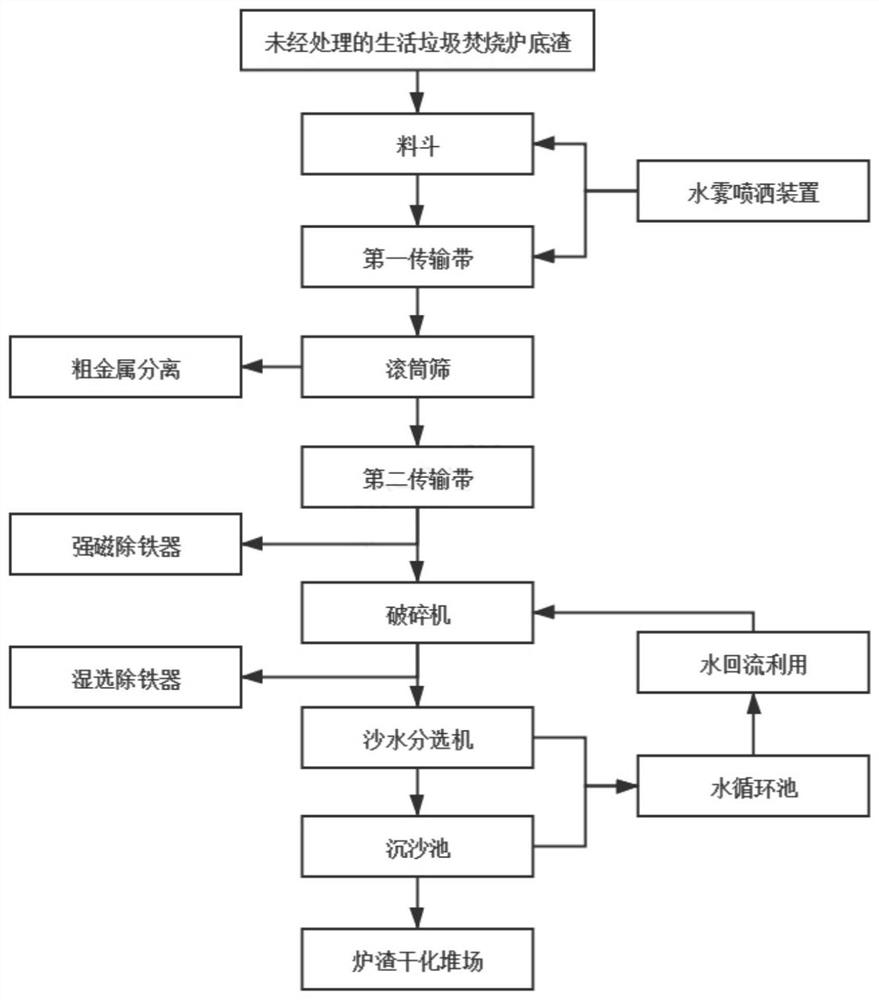

[0037] S01. The untreated domestic waste incinerator bottom slag is subjected to a pretreatment process to remove metals and impurities that are not conducive to building materials, and obtain domestic waste incinerator bottom slag that can be used to prepare dry hard concrete.

[0038] Wherein, the pretreatment process includes the following steps:

[0039] 1) Pour the untreated domestic waste incinerator bottom slag into the hopper, and then transfer it to the drum screen through the first conveyor belt, and use the water mist spraying device to spray the domestic waste incinerator bottom slag on the hopper and the first conveyor belt. Water mist spray cooling;

[0040] 2) The magnetic separation filter device on the drum screen separates the coarse metal from the crushed domestic waste incinerator bottom slag;...

Embodiment 1

[0054] A dry hard concrete with bottom slag of domestic waste incinerator, comprising the following components by mass percentage: 23.7% of bottom slag of domestic waste incinerator, 12.5% of 42.5 grade Portland cement, 55.4% of stone chips, and 8.4% of water; Garbage incinerator bottom slag / (stone chip + domestic waste incinerator bottom slag) ≈ 0.3; domestic waste incinerator bottom slag dry hard concrete ratio ≈ 0.092.

[0055] The preparation method of the above-mentioned domestic waste incinerator bottom slag dry hard concrete comprises the following steps:

[0056] S01. Pretreatment of untreated domestic waste incinerator bottom slag, including the following steps:

[0057] 1) Pour the untreated domestic waste incinerator bottom slag into the hopper, and then transfer it to the drum screen through the first conveyor belt, and use the water mist spraying device to spray the domestic waste incinerator bottom slag on the hopper and the first conveyor belt. Water mist spr...

Embodiment 2

[0072] A dry hard concrete with bottom slag of domestic waste incinerator, comprising the following components by mass percentage: 0% bottom slag of domestic waste incinerator, 12.5% of 42.5 grade Portland cement, 79.1% of stone chips, and 8.4% of water; Garbage incinerator bottom slag / (stone chips + domestic waste incinerator bottom slag) = 0; the water-solid ratio of dry hard concrete with domestic waste incinerator bottom slag is ≈0.092.

[0073] The preparation method of the above-mentioned domestic waste incinerator bottom slag dry hard concrete comprises the following steps:

[0074] S01. Pretreatment of untreated domestic waste incinerator bottom slag, including the following steps:

[0075] 1) Pour the untreated domestic waste incinerator bottom slag into the hopper, and then transfer it to the drum screen through the first conveyor belt, and use the water mist spraying device to spray the domestic waste incinerator bottom slag on the hopper and the first conveyor be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com