Concrete curing system and using process thereof

A maintenance system and concrete technology, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of time-consuming and labor-intensive watering maintenance, reduce construction efficiency, and large labor resources, so as to improve maintenance effects, reduce labor costs, and reduce manual operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

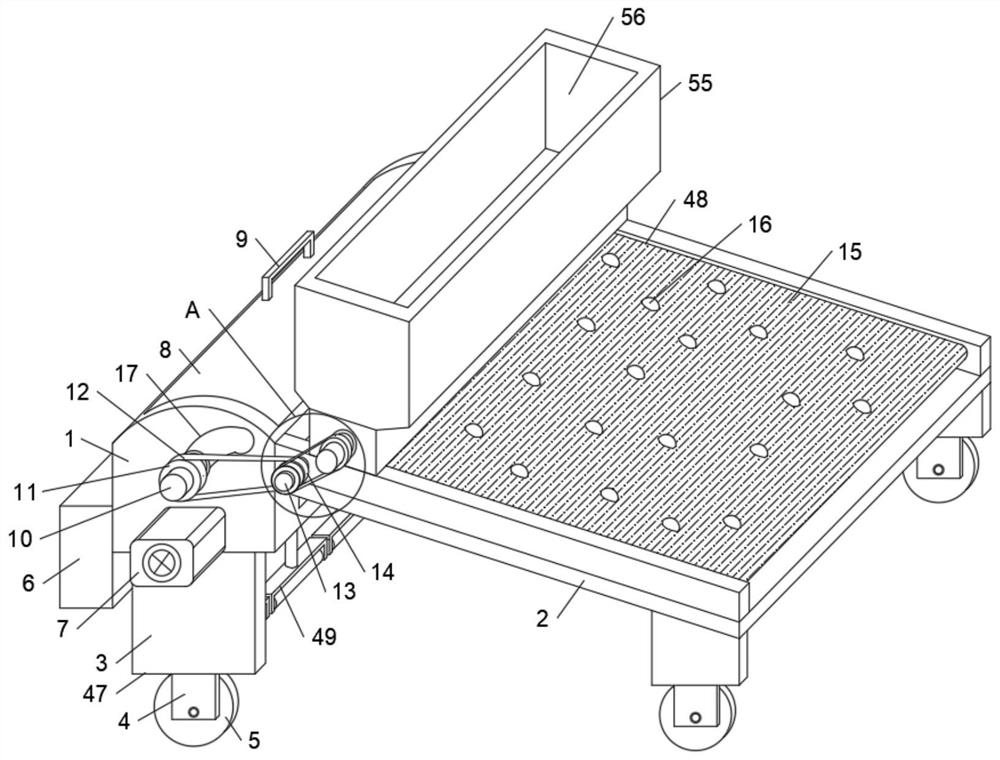

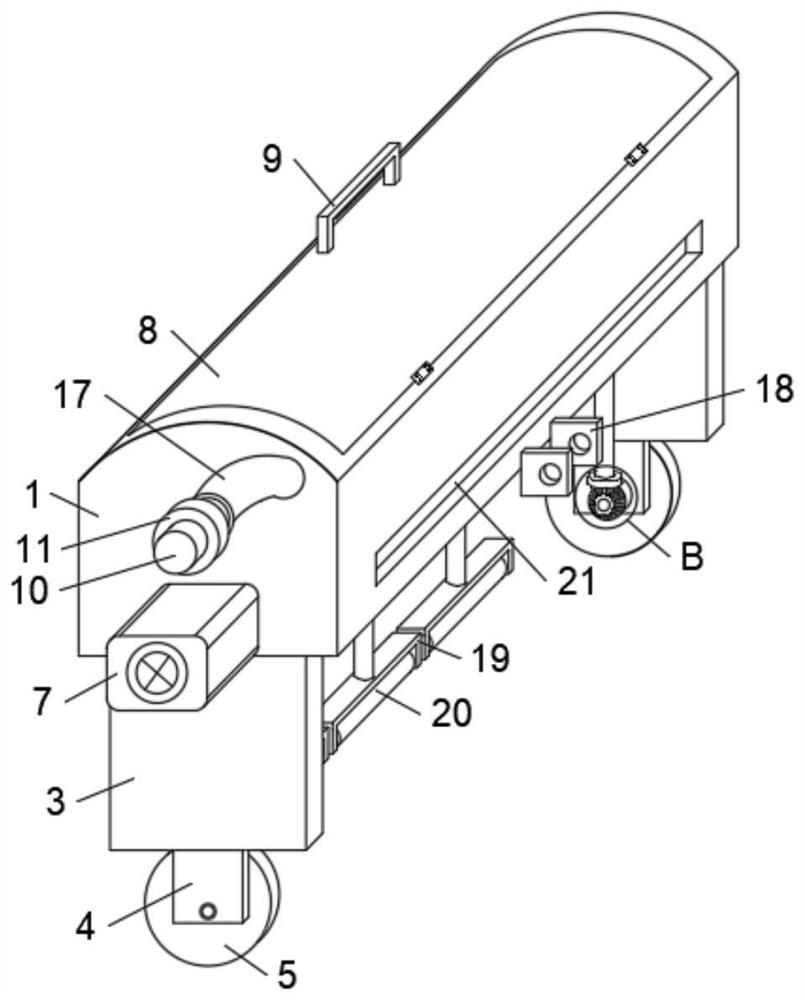

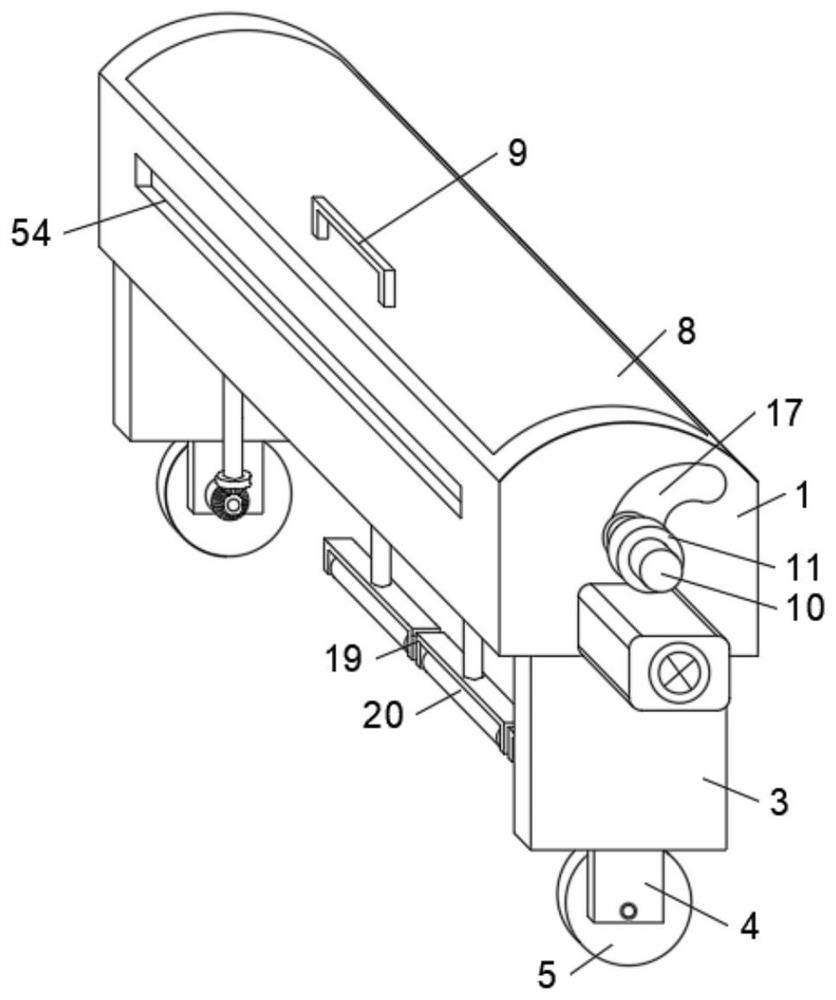

[0050] Such as Figure 1-Figure 16 As shown, the concrete curing system provided by this embodiment includes a housing 1 and a support frame 2 hinged with the housing 1. The upper end of the housing 1 is hinged with a cover 8 through a hinge, and the joint between the cover 8 and the housing 1 is sealed. The front side of the upper end of the body 8 is fixedly provided with a handle 9, and the outer side of the handle 9 is provided with rubber anti-skid lines, the bottom of the casing 1 and the support frame 2 are provided with a moving mechanism 47, and the inside of the casing 1 is provided with a coating mechanism 50 to support The upper part of the frame 2 is provided with a film fixing mechanism 48, the casing 1 is provided with a concrete surface leveling recording mechanism 49, the uppermost part of the support frame 2 is fixedly provided with a feeding mechanism 55, and the film covering mechanism 50 includes a rotating shaft 10 and a rotating shaft 10. The roll film r...

Embodiment 2

[0055] In this example, if figure 2 with Figure 4 As shown, the device can be provided with a smoothing mechanism 52. The smoothing mechanism 52 includes a bracket 22 and a smoothing roller 23. The smoothing roller 23 is rotatably arranged on the inner lower part of the bracket 22, and the bracket 22 is fixedly provided with a connecting block 24. , the position corresponding to the support frame 2 on the shell 1 is fixedly provided with a reserved connecting piece 18, the reserved connecting piece 18 is arranged below the film outlet 21, the reserved connecting piece 18 and the connecting block 24 are connected by a pin shaft, and there is a The smoothing mechanism 52, the connecting block 24, the reserved connecting piece 18 and the pin shaft can be freely installed and disassembled to facilitate the smoothing operation and improve the maintenance effect.

[0056] Such as Figure 1-Figure 16 The use process of a concrete curing system shown includes the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com