Tritium-containing heavy water conveying device

A transmission device, heavy water technology, applied in auxiliary equipment of nuclear power plants, reduction of greenhouse gases, nuclear power generation, etc., can solve the problems of heavy workload, heavy pollution, staff and environmental impact, etc. The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

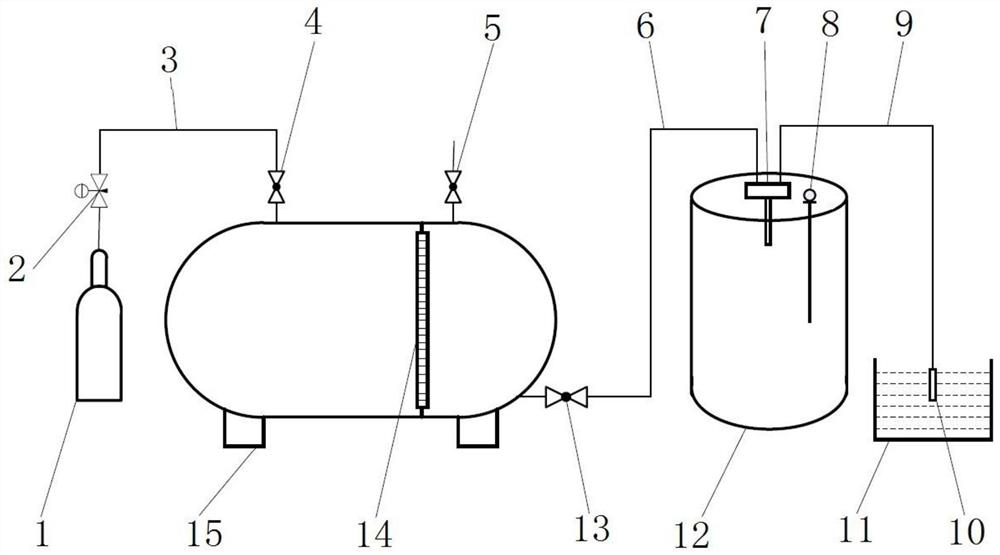

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation conditions.

[0016] The unloading plant of the heavy water reactor nuclear power plant has a special environment, the ground has steps and is uneven, and the heavy water collection tank is large in volume and heavy, so it cannot be moved or lifted directly. If the heavy water in the heavy water collection tank is manually drained, the staff will not only frequently Entering and exiting the unloading plant, the workload is heavy and the dosage is high, and the tritium in the heavy water will spread to the entire unloading plant, which will affect the staff and the plant environment. The tritium-containing heavy water transmission device provided by the present invention uses compressed air to transfer the tritium-containing heavy water in the heavy water collection tank to the heavy water barrel outside the factory building through pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com