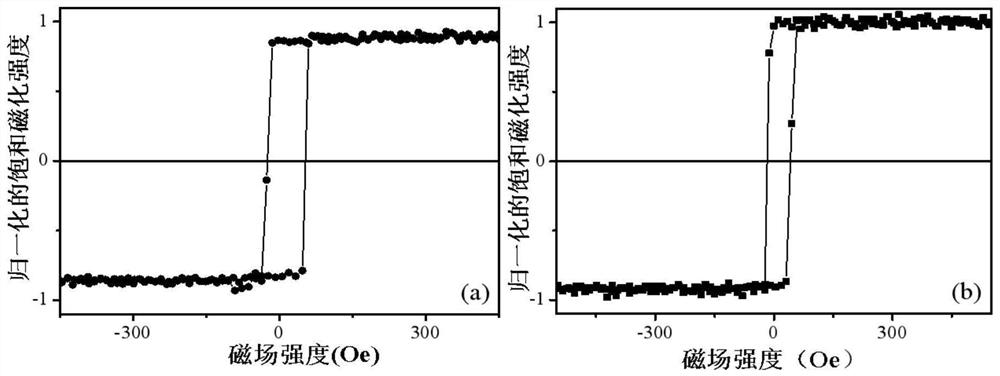

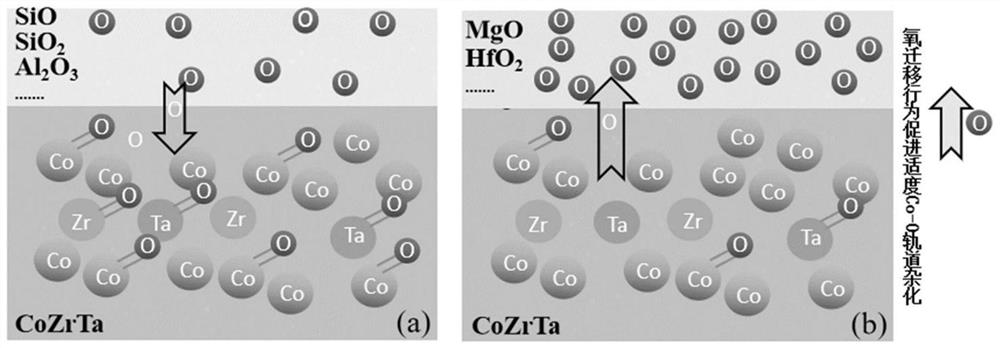

A method for optimizing the magnetic properties of cobalt-based thin-film inductor materials using active metal oxides

An active metal and oxide technology, applied in the application of magnetic films to substrates, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as limiting the coercivity control ability of CoZrTa films, and achieve increased range and controllability. The effect of sex, liveliness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] S1. Clean the surface of the CoZrTa target, the specific cleaning process is as follows:

[0034] (1) Ultrasonic cleaning with acetone alcohol;

[0035] (2) Ultrasonic cleaning with deionized water;

[0036] (3) Finally blow dry by nitrogen.

[0037] S2. Using the magnetron sputtering method, deposit CoZrTa and MgO sequentially on the silicon substrate to form a CoZrTa / MgO structure; first the CoZrTa target is bombarded for 2 minutes and 50 seconds, and then the MgO target is bombarded for 7 minutes and 48 seconds. Bottom vacuum 1×10 -5 Pa, the argon pressure during sputtering is 0.3Pa;

[0038] S3. After the deposition is completed, the sample is subjected to vacuum heat treatment. The process is: the vacuum degree is 1×10 -5 Pa, the heat treatment temperature is 250°C, and the holding time is 30 minutes.

Embodiment 2

[0047] S1. Clean the surface of the CoZrTa target, the specific cleaning process is as follows:

[0048] (1) Ultrasonic cleaning with acetone alcohol;

[0049] (2) Ultrasonic cleaning with deionized water;

[0050] (3) Finally blow dry by nitrogen.

[0051] S2. Using the magnetron sputtering method, sequentially deposit CoZrTa and HfO on the silicon substrate 2 , forming CoZrTa / HfO 2 Structure; first CoZrTa target bombardment for 3 minutes, then HfO 2 The target is bombarded for 3 minutes and 1 second, and the background vacuum of the sputtering chamber is 1×10 -5 Pa, the argon pressure during sputtering is 0.3Pa;

[0052] S3. After the deposition is completed, the sample is subjected to vacuum heat treatment. The process is: the vacuum degree is 1×10 -5 Pa, the heat treatment temperature is 250°C, and the holding time is 30 minutes.

Embodiment 3

[0064] S1. Clean the surface of the CoZrTaB target, the specific cleaning process is as follows:

[0065] (1) Ultrasonic cleaning with acetone alcohol;

[0066] (2) Ultrasonic cleaning with deionized water;

[0067] (3) Finally blow dry by nitrogen.

[0068] S2. Using the magnetron sputtering method, sequentially deposit CoZrTaB and HfO on the silicon substrate 2 , forming CoZrTaB / HfO 2 Structure; first CoZrTaB target bombardment for 3 minutes and 7 seconds, then HfO 2 The target is bombarded for 3 minutes and 1 second, and the background vacuum of the sputtering chamber is 1×10 -5 Pa, the argon pressure during sputtering is 0.3Pa;

[0069] S3. After the deposition is completed, the sample is subjected to vacuum heat treatment. The process is: the vacuum degree is 1×10 -5 Pa, the heat treatment temperature is 250°C, and the holding time is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com