Installation climbing piece for direct-current supporting capacitor

A DC support and capacitor technology, applied in the direction of capacitors, electrical components, etc., can solve the problems that affect the installation dimension accuracy, the welding heat affects the deformation of the box shell, and affects the appearance of the appearance, so as to reduce the welding workload and structure. Simple, aesthetically-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

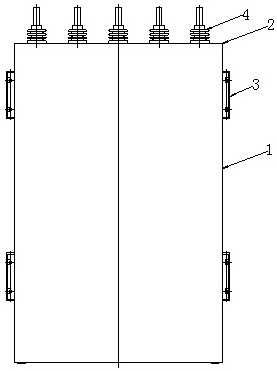

[0030] exist figure 1 It can be seen in the figure that the appearance of the DC support capacitor is composed of the DC support capacitor case (1), the DC support capacitor cover (2), the mounting plate (3), and the DC support capacitor terminal (4).

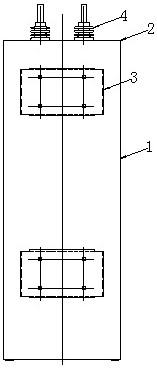

[0031] figure 2 yes figure 1 left illustration of .

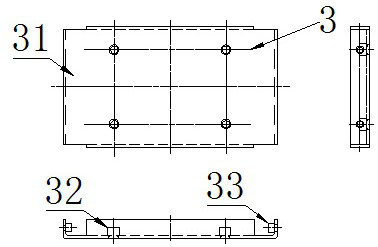

[0032] From image 3 and Figure 4 Visible in:

[0033] The installation climb (3) is mainly composed of the installation climbing board (31), the first welding nut (32) and the second welding nut (33); the installation climbing board (31) includes the installation of the climbing board body (311), the second One installation hole (312) and the second installation hole (313); the installation climbing board body (311) is an integrated structure, its four sides are folded at right angles, and its surface has 4 first installation holes (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com