Lithium ion battery diaphragm cutting and positioning device

A lithium-ion battery and positioning device technology, which is applied to secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of low safety, low pass rate, and low efficiency of manual cutting, and reduce manpower Consumption, improve the qualified rate and efficiency, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

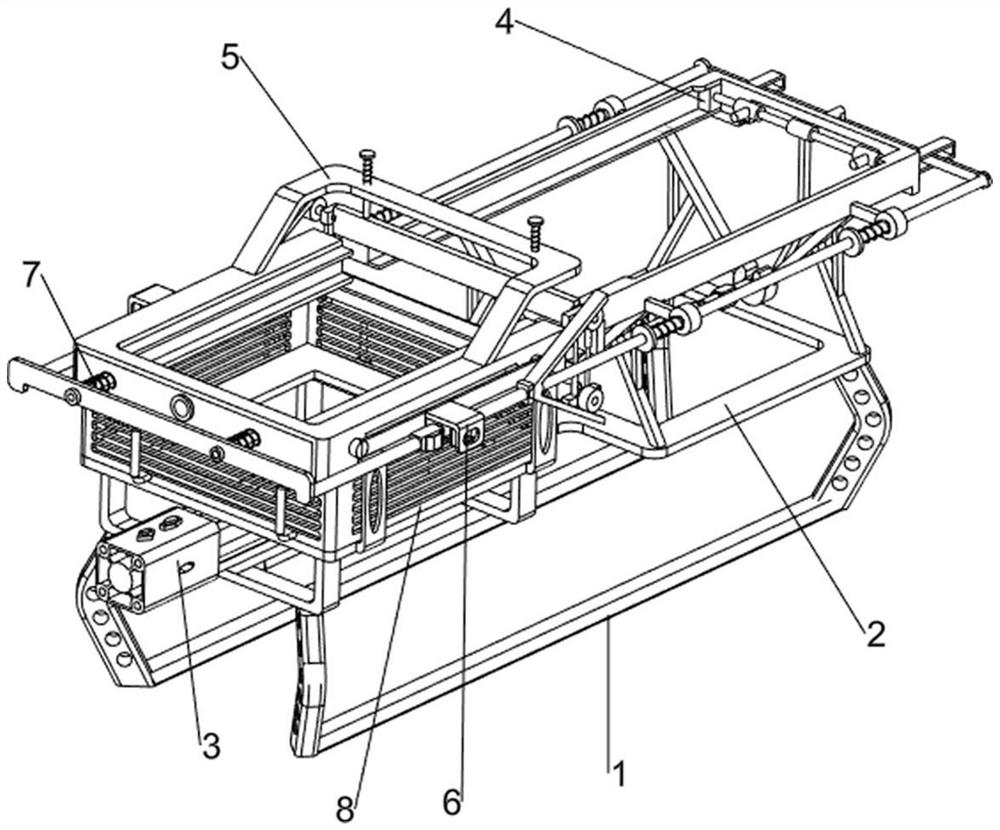

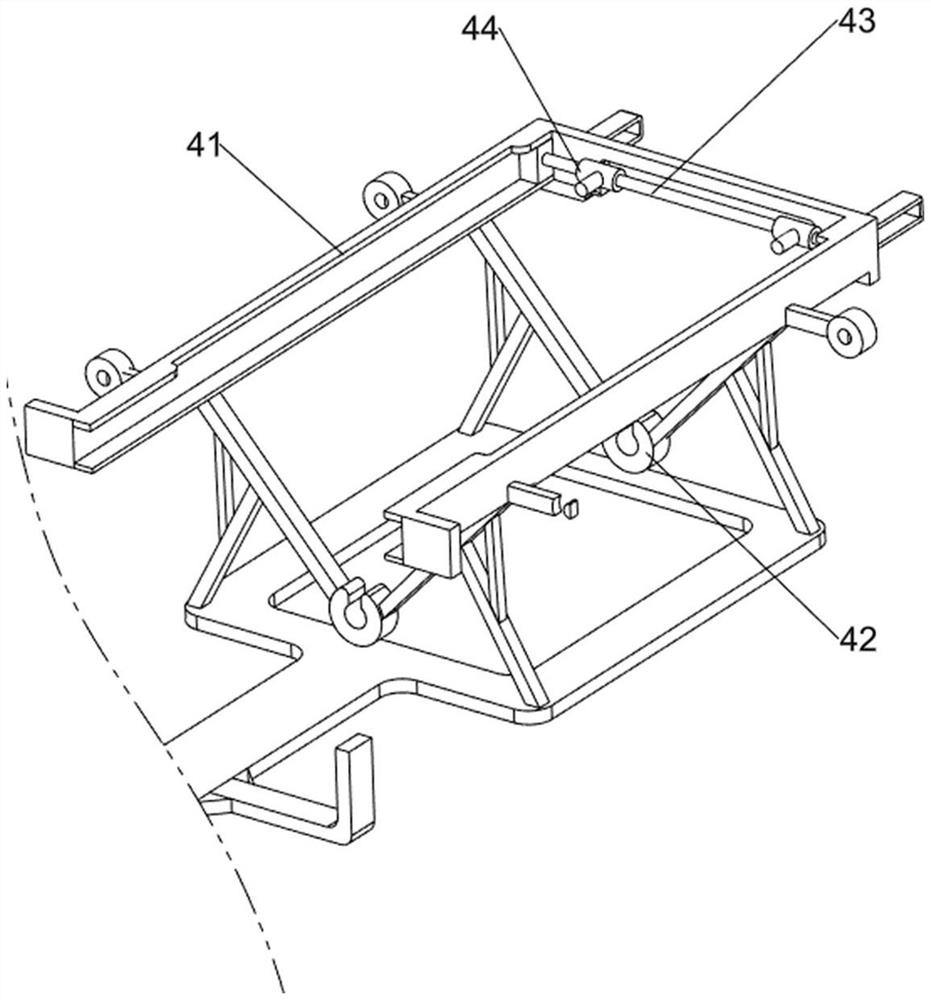

[0067] A lithium-ion battery diaphragm cutting positioning device, such asfigure 1 and figure 2 As shown, it includes a base 1, a working frame 2, a pulling mechanism 3, a sliding mechanism 4 and a cutting mechanism 5. The middle part of the base 1 is provided with a working frame 2, and the upper side of the working frame 2 is provided with a pulling mechanism 3. A sliding mechanism 4 is provided, and the sliding mechanism 4 is connected with the pulling mechanism 3. The front part of the working frame 2 is provided with a cutting mechanism 5, and the cutting mechanism 5 cooperates with the sliding mechanism 4.

[0068] When people are ready to cut off the lithium battery diaphragm, the lithium battery is placed in the sliding mechanism 4 first, and the pulling mechanism 3 is started at this time, the pulling mechanism 3 will drive the sliding mechanism 4 to move forward, and the sliding mechanism 4 will drive the lithium battery to move forward In the cutting mechanism 5, t...

Embodiment 2

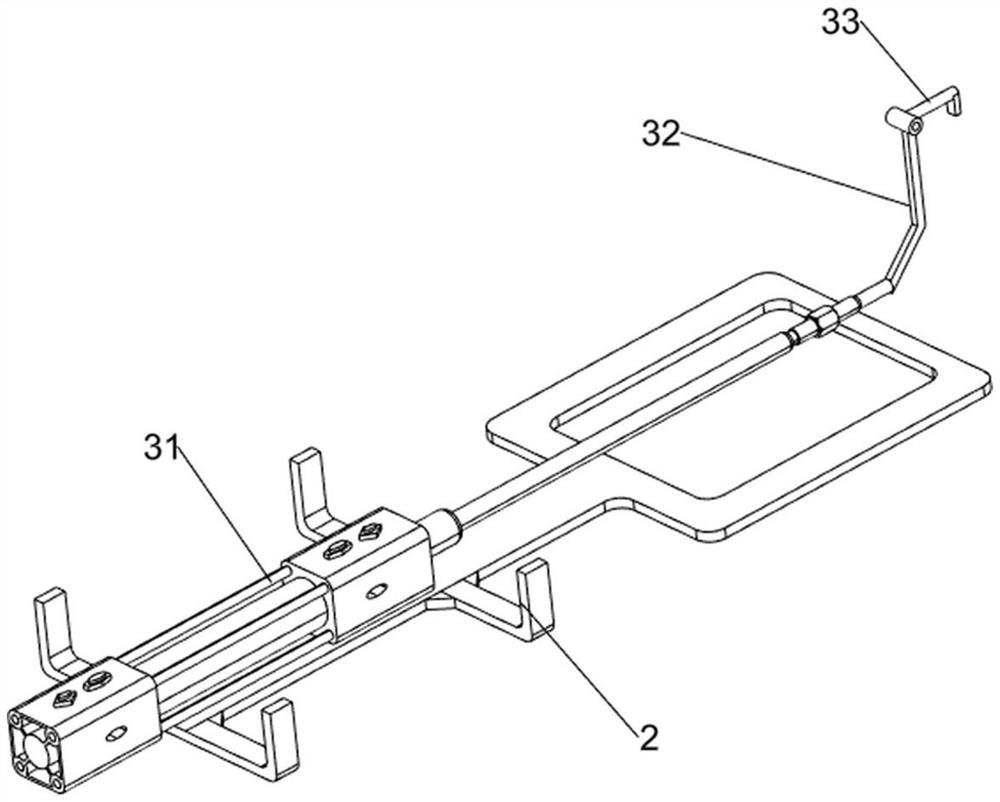

[0070] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 and Figure 9 As shown, the pulling mechanism 3 includes a cylinder 31, a first connecting rod 32 and a first connecting block 33, and the upper side of the front part of the work frame 2 is equipped with a cylinder 31, and the cylinder 31 is provided with a first connecting rod 32, and the first connecting rod 32 is provided with a first connection block 33 on the top.

[0071] When people are ready to cut off the lithium battery diaphragm, the lithium battery is first placed in the sliding mechanism 4, and the cylinder 31 is started at this time, and the cylinder 31 will drive the first connecting rod 32 to move forward, and the first connecting rod 32 will drive the first connecting rod 32 to move forward. The block 33 moves forward, and the first connecting block 33 will drive the sliding mechanism 4 to move forward, and the sliding mechanism 4 will drive the...

Embodiment 3

[0077] On the basis of Example 2, such as figure 1 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a blanking mechanism 6, and the blanking mechanism 6 includes a second pull rod 61, a fifth connecting rod 62, an extruding block 63, a second connecting block 64, a fourth compression spring 65, and a third connecting block 66 , rotating block 67 and torsion spring 68, the special-shaped block 511 front portions on the left and right sides are provided with the second pull rod 61, the fifth connecting rod 62 is provided at the front portion of the second pull rod 61, and the middle part of the second pull rod 61 is provided with extruding Block 63, the left and right sides of the material storage frame 51 are all slidingly connected with the second connecting block 64, and the second connecting block 64 is wound with two fourth compression springs 65, and the fourth compression spring 65 is connected with the material storage frame 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com