Clean and environment-friendly anti-clogging vibration screening closed bin structure

A vibratory screening, clean and environmentally friendly technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of easy blockage of dust bag, easy blockage in the screen hole, poor anti-blocking effect of the sieve plate, etc., to ensure the screening Utilization rate, convenient for uniform screening, and improved screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

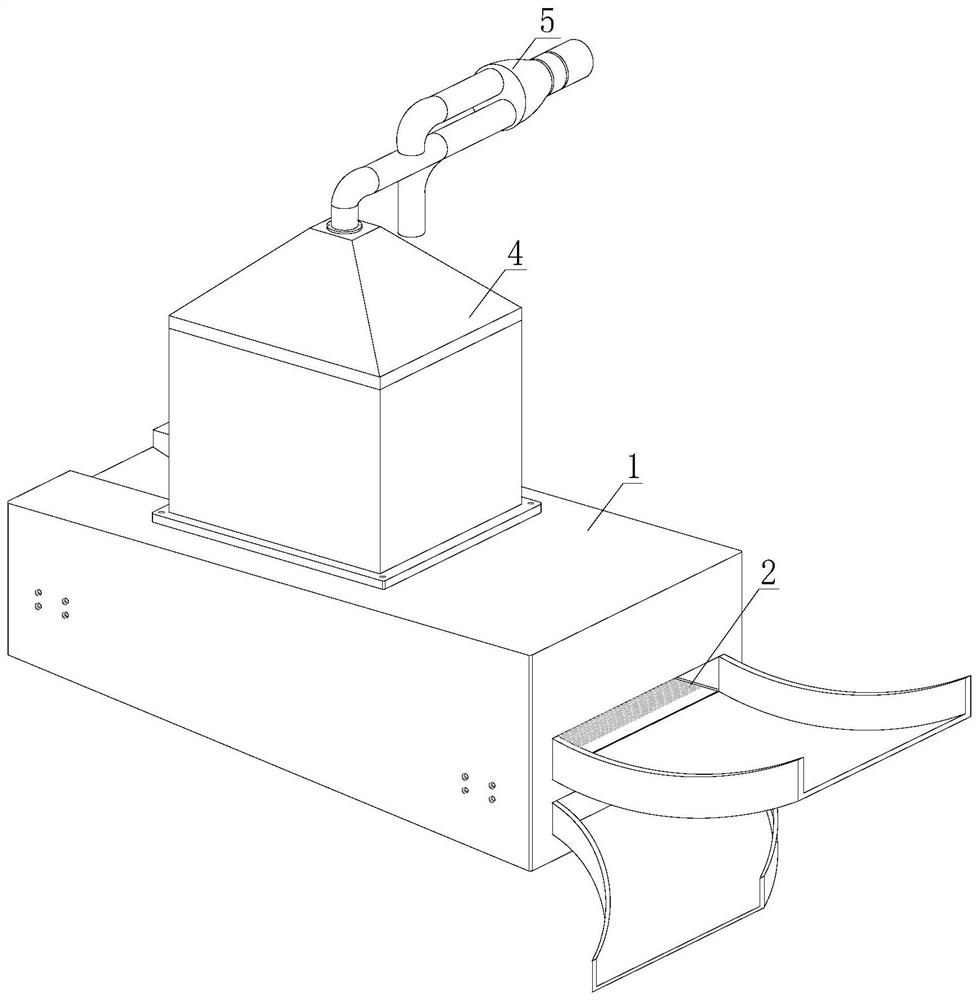

[0036] see Figure 1-2 , an anti-clogging vibrating screening closed bin structure for cleaning and environmental protection, including a vibrating screen main body 1, a sieve plate 2, an anti-blocking mechanism 3, a closed bin 4 and a dust removal assembly 5, and the sieve plate 2 is arranged on the vibrating screen main body 1 Inside, the anti-blocking mechanism 3 is set on the outside of the sieve plate 2 inside the vibrating screen main body 1, the closed bin 4 is installed on the upper end of the feeding end of the vibrating screen main body 1, and the dust removal assembly 5 is arranged in the middle of the upper end of the closed bin 4.

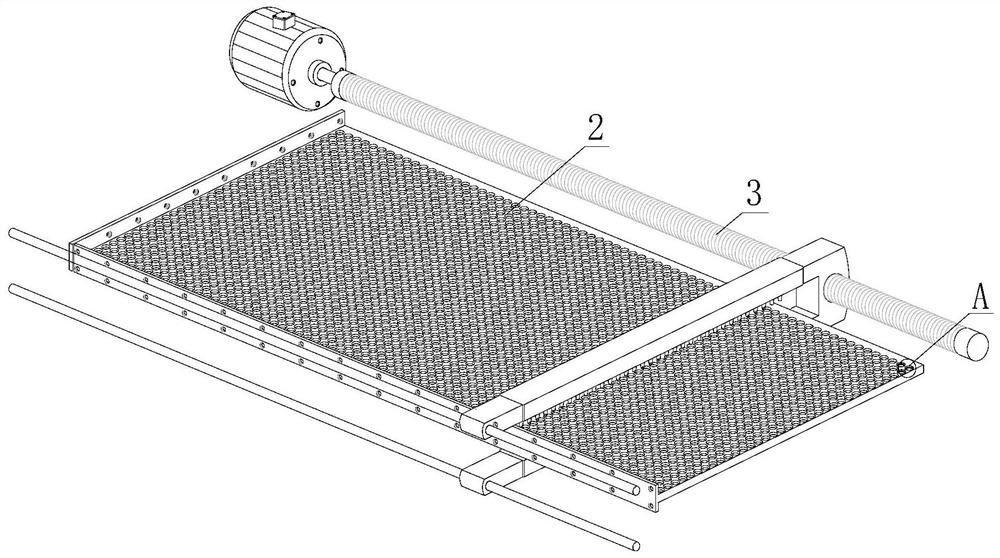

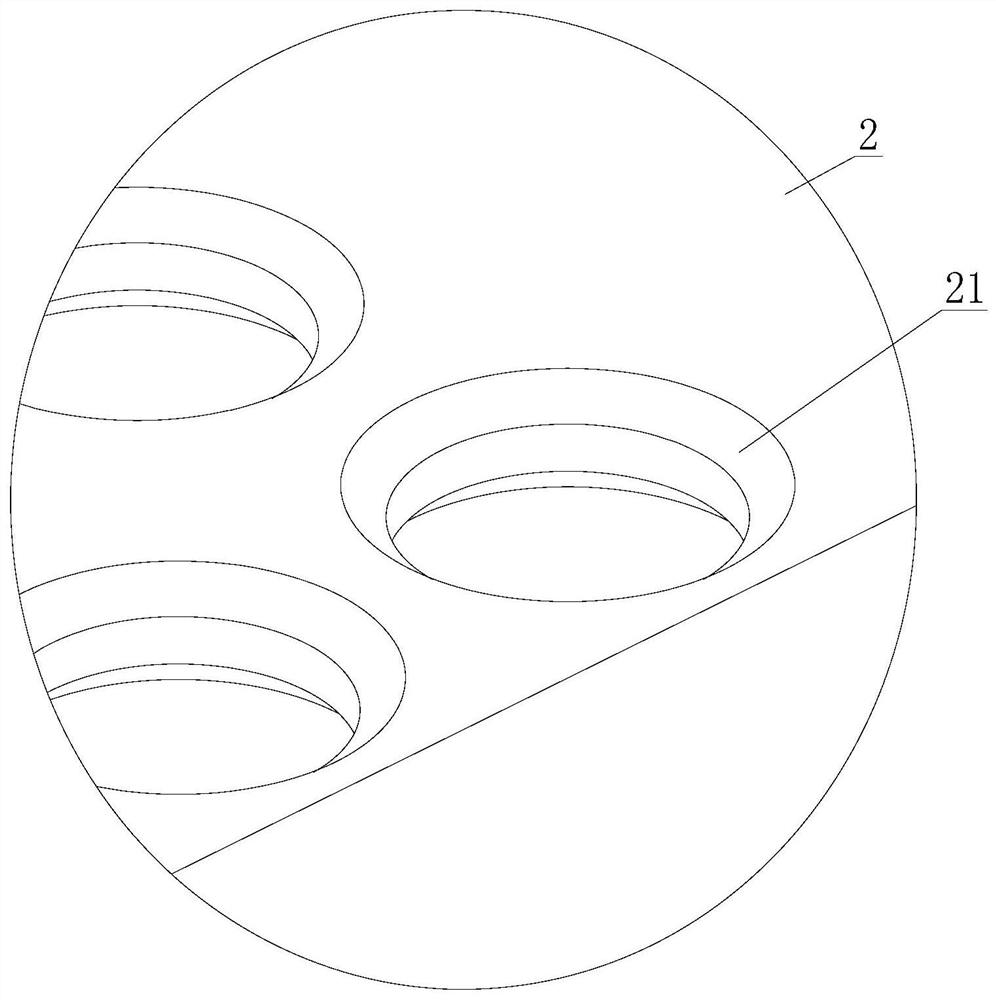

[0037] see Figure 3-8 , an anti-clogging vibrating screening closed bin structure for cleaning and environmental protection, the anti-blocking mechanism 3 includes a servo motor 31, a screw rod 32, a first stabilizing rod 33, a second stabilizing rod 34, a moving connecting block 35, and an anti-blocking assembly 36. The first moving...

Embodiment 2

[0044] see Figure 1-2 , an anti-clogging vibrating screening closed bin structure for cleaning and environmental protection, including a vibrating screen main body 1, a sieve plate 2, an anti-blocking mechanism 3, a closed bin 4 and a dust removal assembly 5, and the sieve plate 2 is arranged on the vibrating screen main body 1 Inside, the anti-blocking mechanism 3 is set on the outside of the sieve plate 2 inside the vibrating screen main body 1, the closed bin 4 is installed on the upper end of the feeding end of the vibrating screen main body 1, and the dust removal assembly 5 is arranged in the middle of the upper end of the closed bin 4.

[0045] see Figure 3-8 , an anti-clogging vibrating screening closed bin structure for cleaning and environmental protection, the anti-blocking mechanism 3 includes a servo motor 31, a screw rod 32, a first stabilizing rod 33, a second stabilizing rod 34, a moving connecting block 35, and an anti-blocking assembly 36. The first moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com