A coal-fired unit boiler high-pressure feed water micro-oxygen precise control method and device

A technology for high-pressure water supply and coal-fired units, applied in water treatment parameter control, water supply control, chemical instruments and methods, etc., can solve problems such as spalling effect, accelerated superheater, etc., achieve low risk, reduce deposition rate and salt accumulation rate , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

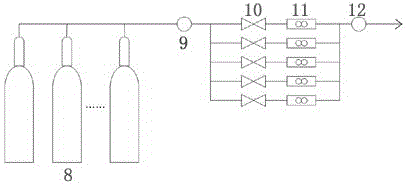

[0024] Such as figure 2 As shown, a coal-fired unit boiler high-pressure feed water micro-oxygen precision control device, which includes sequentially connected oxygen cylinder group 8, a first pressure reducing valve 9 and a second pressure reducing valve 12, the first pressure reducing valve 9 The pipeline between the second decompression valve 12 is composed of 5 oxygenation branches connected in parallel; a valve 10 and a flow meter 11 are arranged on the oxygenation branch; the oxygenation branch is a stainless steel with an effective diameter of 1mm Tube. The second decompression valve 12 is connected to the feed water oxygenation point. The oxygen cylinder group 8 is several oxygen cylinders.

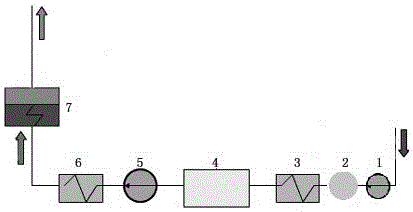

[0025]A precise control method for micro-oxygen in high-pressure feed water of a coal-fired unit boiler, specifically: before adding oxygen to the feed water, stop adding hydrazine, close the exhaust valve of the deaerator, and control the hydrogen conductance of the thermal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com