Building material cleaning and polishing device

A technique for polishing devices and building materials, applied to cleaning methods and tools, cleaning methods using tools, and cleaning methods using liquids, etc., can solve the problems of difficult separation of impurities and pebbles, slow cleaning of pebbles, and unclean cleaning, etc., to achieve Ensure cleaning speed and fluency, improve efficiency, and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

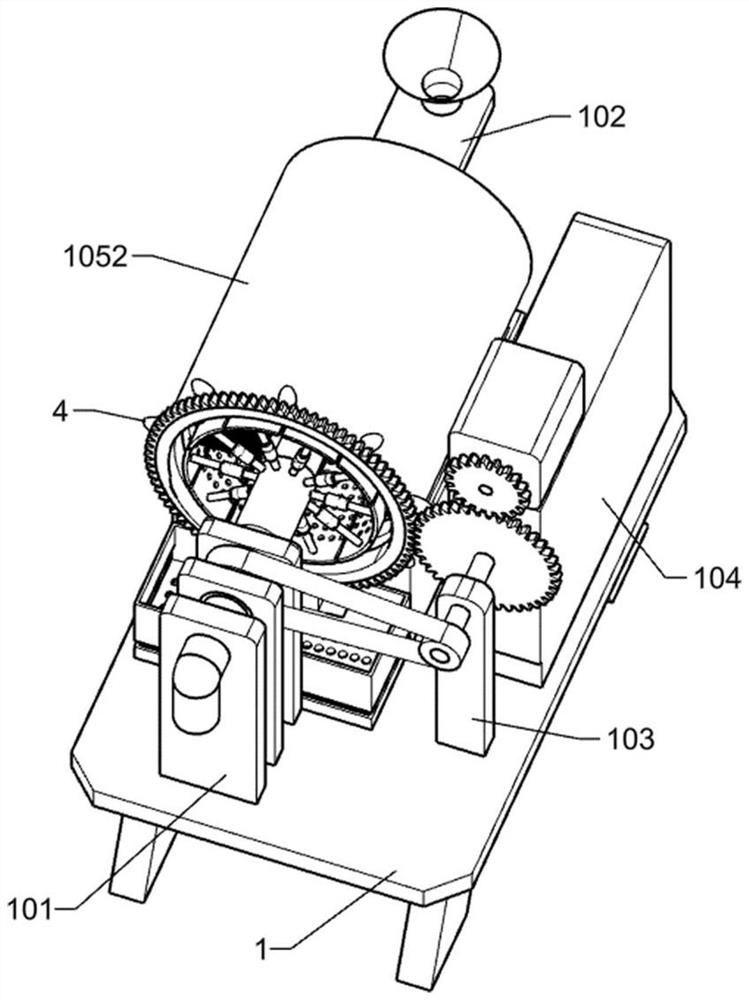

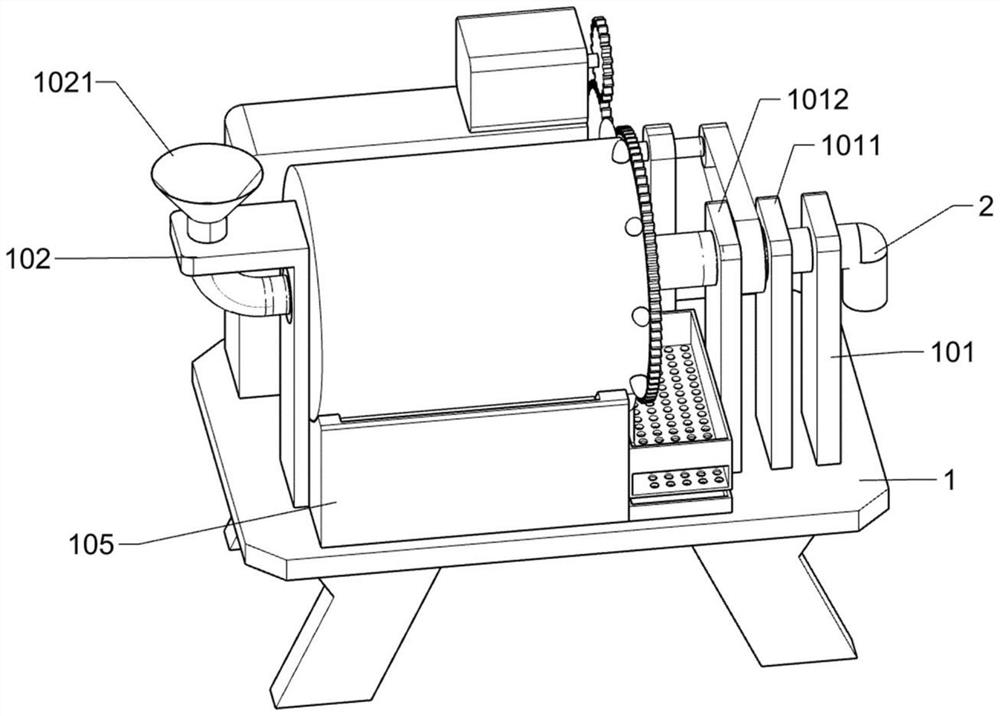

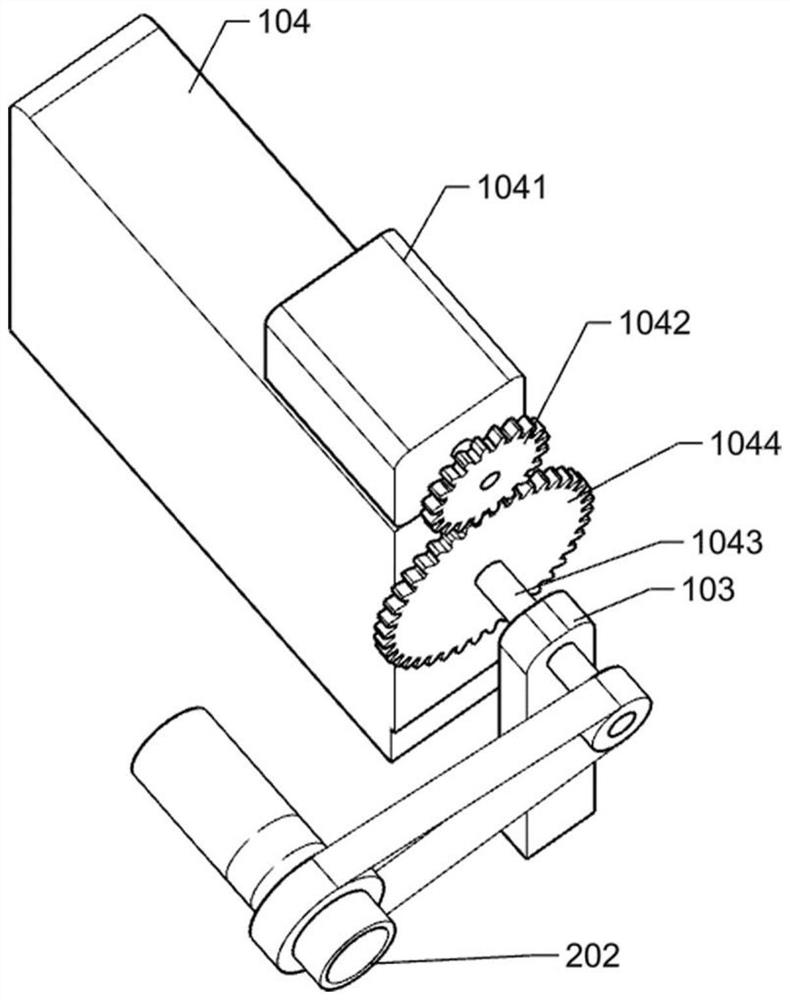

[0068] Such as Figure 1-8 As shown, a building material cleaning and polishing device includes a base 1, a first front support board 101, a second front support board 1011, a third front support board 1012, an L-shaped rear support board 102, a feeding funnel 1021, and a shaft Support plate 103, motor bracket 104, servo motor 1041, pinion gear 1042, major shaft 1043, large gear 1044, small pulley 1045, large pulley 1046, belt 1047, barrel bracket 105, roller 1051, threaded barrel 1052, outer Gear 1053, water pipe 2, spray gun 201, sleeve 202, axle sleeve 208, concave rod 203, first spring 204, convex rod 205, fan-shaped funnel 206 and soft brush 207, base 1 is that a bottom is provided with four table legs The table frame, the first front support plate 101, the first front support plate 101 is fixedly connected to the front end of the base 1, the second front support plate 1011 is fixedly connected to the base 1, and is located at the rear side of the first front support plat...

Embodiment 2

[0071] According to embodiment 1, as Figure 7 As shown, a building material cleaning and polishing device includes a cleaning brush 3, which is fixedly connected to the outer wall on the left side of the water pipe 2, and the cleaning brush 3 is in contact with the round hole of the fan-shaped funnel 206.

[0072] Working principle: When cleaning cobblestones, since a large amount of water is needed for flushing, there are many circular holes on the fan-shaped funnel 206. Although these holes have the function of water leakage, it is inevitable that some smaller pebbles will be stuck in the In the circular hole, in order to prevent the pebbles from blocking the circular hole, a device for clearing the hole - a cleaning brush 3 is installed. One side of the cleaning brush 3 is connected to the outer wall of the water pipe 2, and the brush at the other end passes through the fan-shaped hole. The circular aperture on the funnel 206, so, when fan-shaped funnel 206 rotates, cleani...

Embodiment 3

[0074] According to embodiment 2, as Figure 9 and Figure 10 As shown, a building material cleaning and polishing device includes a trigger block 4, a vibration chamber 401, a second spring 402, a block 403 and a storage box 404, the storage box 404 is placed on the base 1, and the storage box 4 is located on the front support plate 101 Between the threaded barrel 1052, the vibration bin 401 is located directly above the storage box 404. The vibration bin 401 is slidingly connected with the threaded barrel 1052 and the third support plate. The vibration bin 401 is a rectangular accommodation bin with protrusions on both sides. The bottom of the bin 401 is provided with countless small holes, one bump is provided on the front side of the vibration bin 401, two bumps are arranged on the rear side of the vibration bin 401, and the upper end of the second spring 402 is fixedly connected to the bumps on both sides of the vibration bin 401. The bottom of the block, the lower end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com