Preparation method and production equipment of high-sphericity gas atomization powder

A production equipment and high sphericity technology, applied in the field of powder metallurgy, can solve the problems of low sphericity, the sphericity of gas atomized powder needs to be further improved, and easy to produce coated balls, etc., to achieve high sphericity, increase expansion, and improve The effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The metal powder was prepared by the above-mentioned preparation method and production equipment. Each experimental sample used different liquid outlet diameters, liquid flow rates of the melt, and atomizing gas medium temperature to verify the influence of each process parameter on the powder-making effect. The following experimental samples The preparation method comprises the following steps:

[0045] (1) Smelting: After preparing industrial pure iron, metal silicon, and pure aluminum particles according to the mass percentage of 85%, 9.6%, and 5.4%, they are sequentially added to the induction furnace for vacuum melting, and the temperature is raised. After the heat preservation operation, the molten steel meets After the request, the molten steel is poured, and the molten steel flows down from the leaking bag;

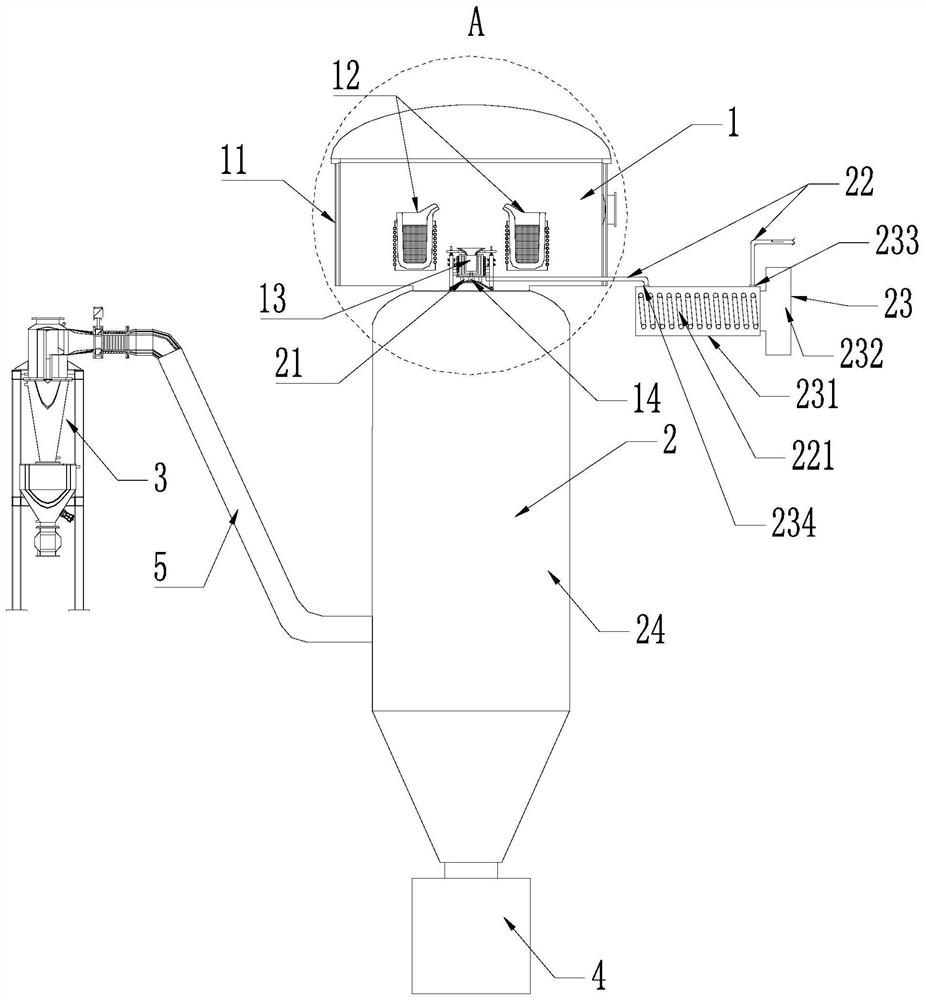

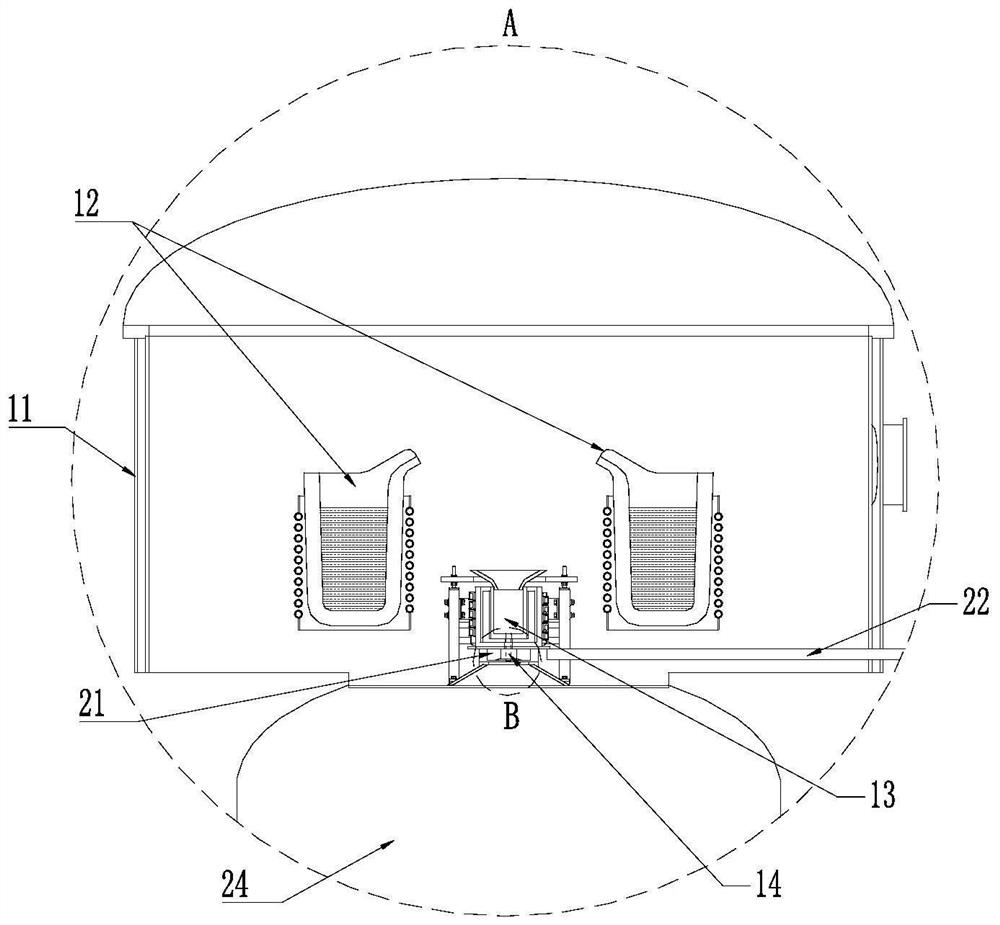

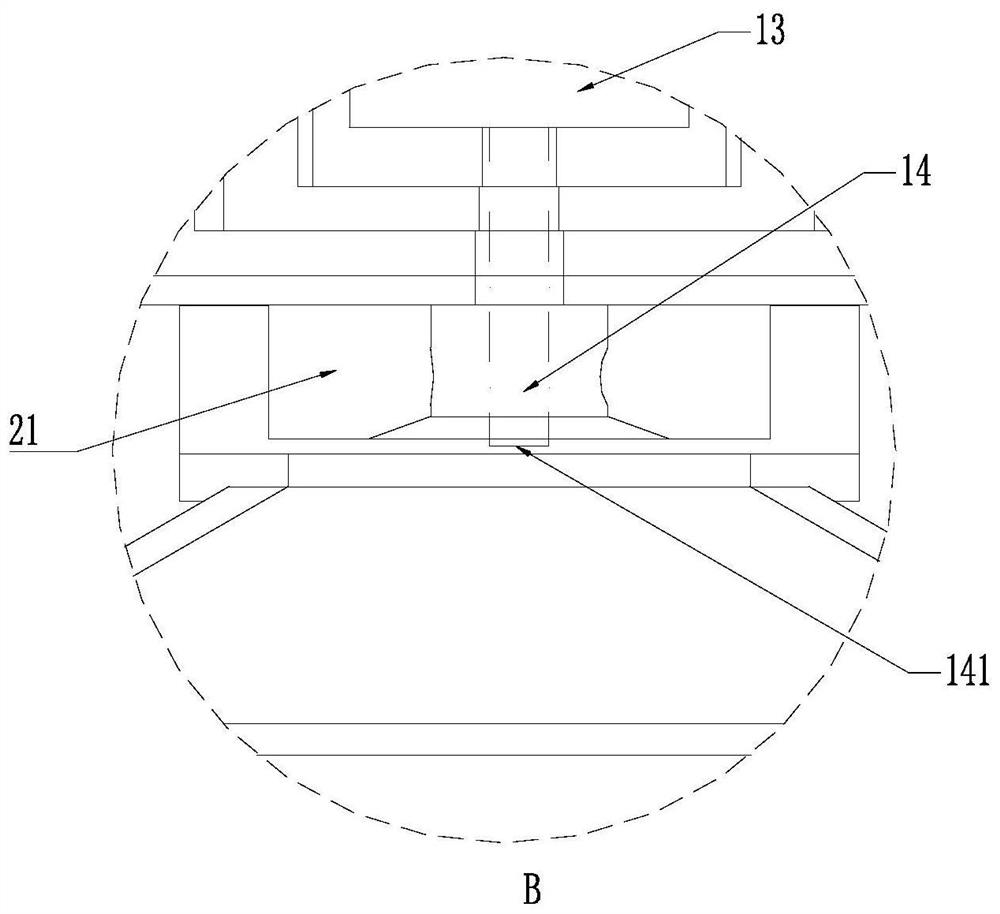

[0046] (2) Atomization: After preheating the nitrogen gas to the design temperature, the nitrogen gas is passed into the atomizing nozzle 21 to atomize the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com