Door and window aluminum alloy frame corner assembling mechanical equipment

An aluminum alloy frame and mechanical equipment technology, applied in metal processing equipment, metal processing, manufacturing tools and other directions, can solve the problems of insufficient processing accuracy, small adjustment range, large energy demand, etc. Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

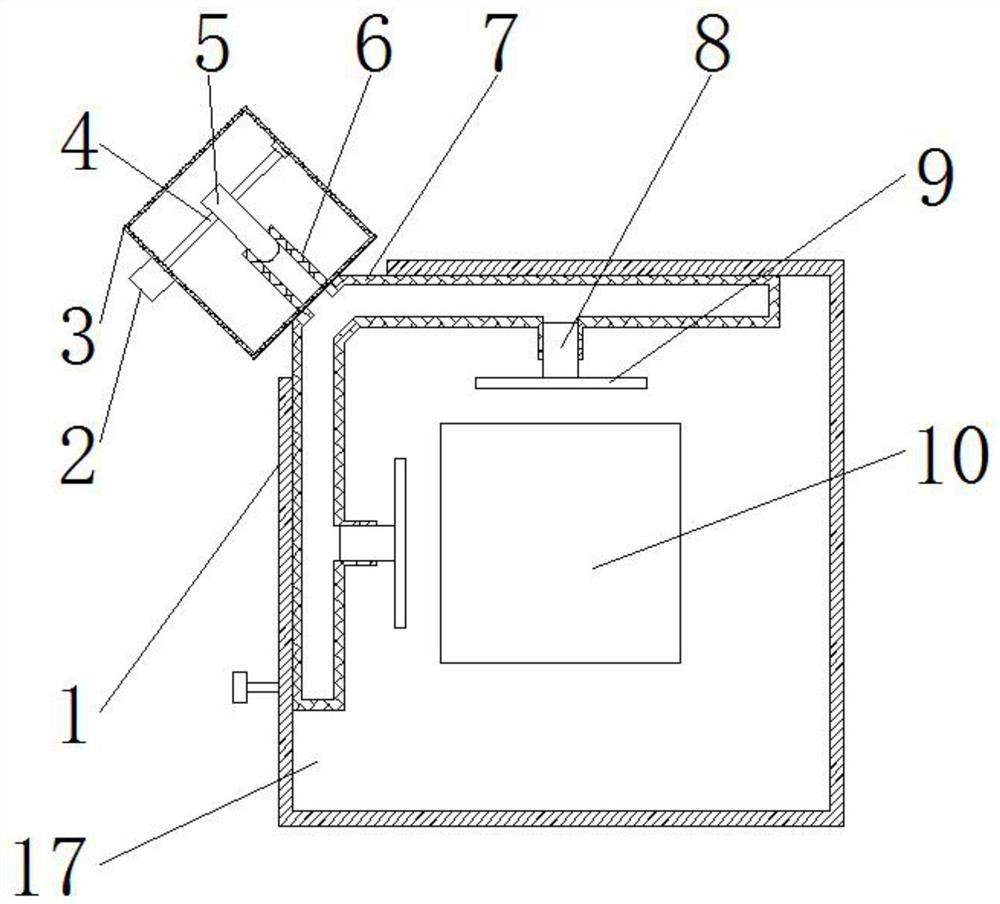

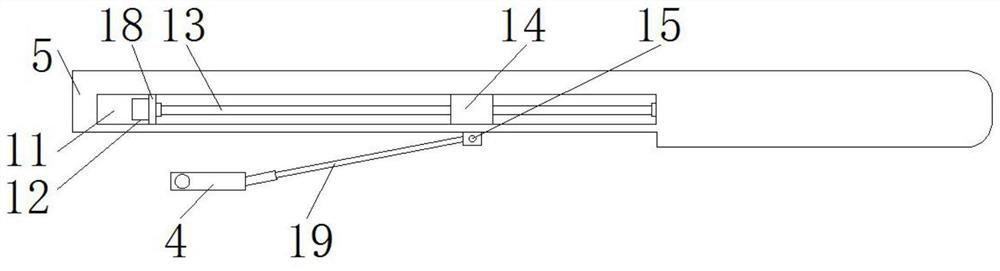

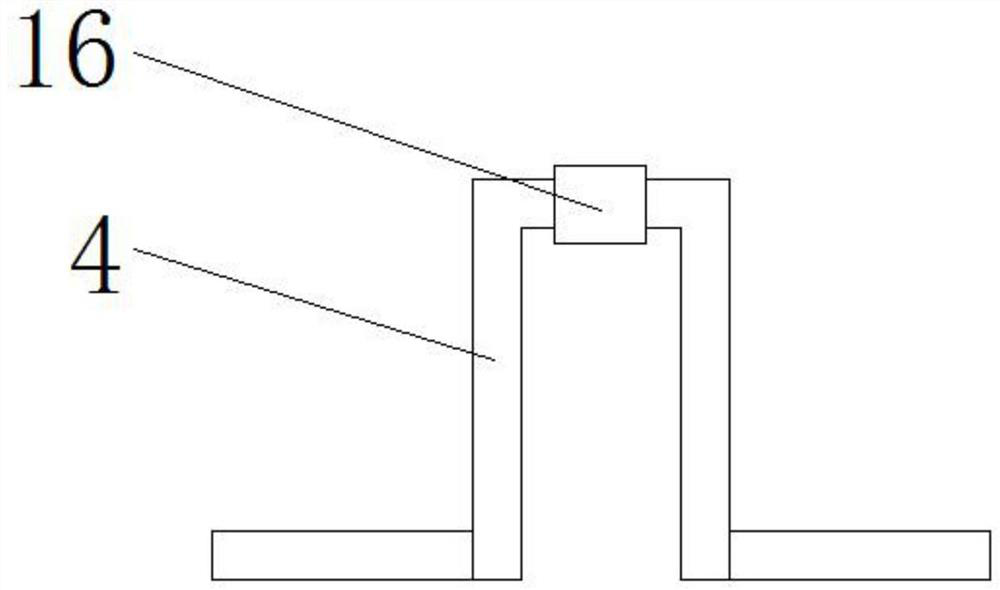

[0025] Such as Figure 1-3 As shown, the embodiment of the present invention provides a door and window aluminum alloy frame corner mechanical equipment, including a workbench 1, an installation box 3, a first motor 2, a brake cylinder 7, a guide pipe 6 and a working groove 17, and the working groove 17 is opened On the top of the workbench 1, a brake cylinder 7 is fixedly installed inside the working groove 17, the guide pipe 6 is connected with the side wall of the brake cylinder 7, the installation box 3 is fixedly connected with the side wall of the brake cylinder 7, and the guide The end of the pipeline 6 away from the brake cylinder 7 runs through the side wall of the installation box 3 and extends to the inside, the first motor 2 is fixedly connected to the outer side wall of the installation box 3, and the driving end of the first motor 2 runs through the side wall of the installation box 3 And extend to its inside, the inside of the working tank 17 is fixedly equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com